ZnO/AlN/Si multi-layer structure film and preparation method and application thereof

A multi-layer structure and thin film technology, applied in the coating, superimposed layer plating, metal material coating process and other directions, can solve the problems that piezoelectric thin film materials cannot be integrated with semiconductor Si process, and the preparation cost is high, and achieves low cost, The effect of simple equipment and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

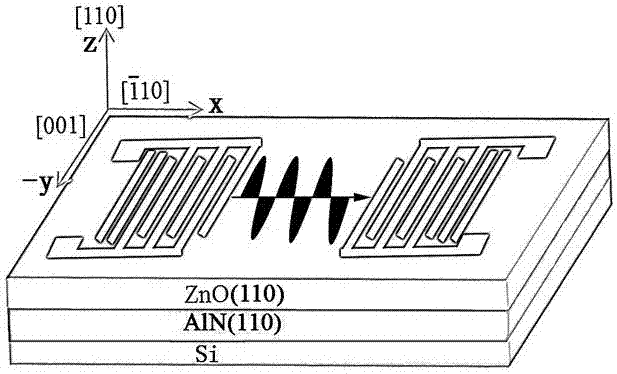

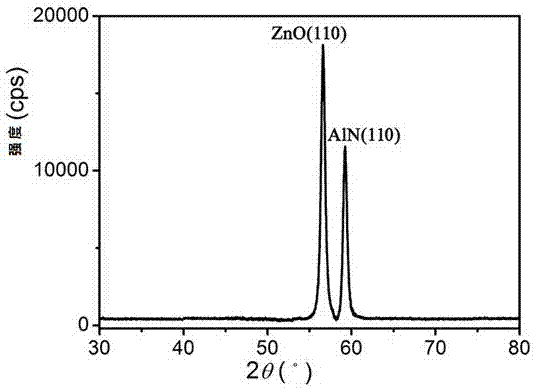

[0037] The polished Si(100) single crystal substrate was ultrasonically cleaned with acetone, alcohol, and deionized water for 10 min, then dried with a nitrogen gun, and installed on the substrate holder in the magnetron sputtering vacuum chamber. Al target and After the Zn target is installed, start vacuuming. When the vacuum degree is higher than 10 -5 After Pa, argon gas was introduced and the Al target was pre-sputtered for 8 min to remove the contamination on the surface of the Si substrate. Introduce nitrogen gas as the reaction gas, adjust the working pressure to 1.2Pa, the ratio of the flow rate of nitrogen gas and argon gas to 0.6, the gas flow rate to 40 sccm, the sputtering power to 80W, the substrate temperature to 250°C, and adjust the substrate negative bias voltage to 100V. The deposition time was controlled to be 30 min, and the AlN thin film with (110) preferred orientation was deposited. Then use Zn target reactive magnetron sputtering to deposit ZnO thin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com