A method for improving the magnetron sputtering deposition rate of SiO2 thin film

A technology of magnetron sputtering and deposition rate, applied in the direction of sputtering plating, ion implantation plating, metal material coating process, etc., can solve the problem of time-consuming, index parameters are easy to change, and reactive sputtering is easy to enter the metal mode and other issues to achieve the effect of reducing production costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

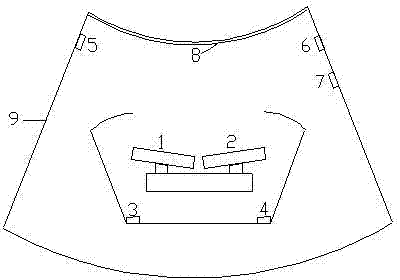

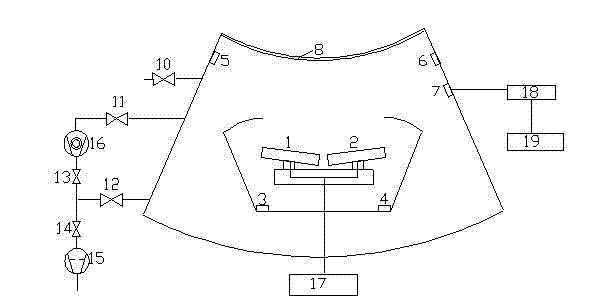

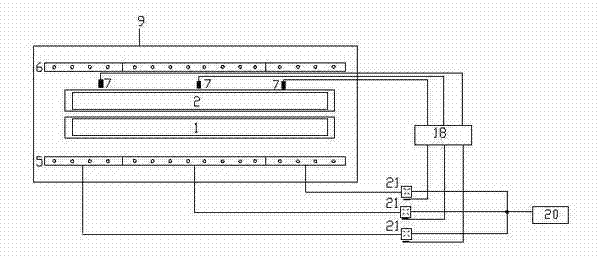

[0024] Attached below figure 1 , 2 , 3 The present invention is described in detail: a kind of improving SiO 2 Thin film magnetron sputtering deposition rate method, the plasma emission detection system is used to monitor the plasma emission spectrum of intermediate frequency reactive magnetron sputtering in real time, and the reactive magnetron sputtering is stabilized at any working point in the transition state according to the set value of the detection system;

[0025] The gas atmosphere is: process gas argon and reaction gas oxygen; the process gas is placed below the twin targets, and the reaction gas is placed above the twin targets;

[0026] This method requires the use of an online monitoring SiO 2 Thin film magnetron sputtering deposition rate device, which includes the following components:

[0027] Twin target position Ⅰ1, twin target position Ⅱ2, process gas inlet Ⅰ3, process gas inlet Ⅱ4, reaction gas inlet Ⅰ5, reaction gas inlet Ⅱ6, optical fiber probe 7, su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com