Light emitting diode and manufacture method thereof

A technology of light-emitting diodes and manufacturing methods, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve problems such as the influence of epitaxial layer growth, and achieve the effects of improving light extraction efficiency and reducing crystal defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings.

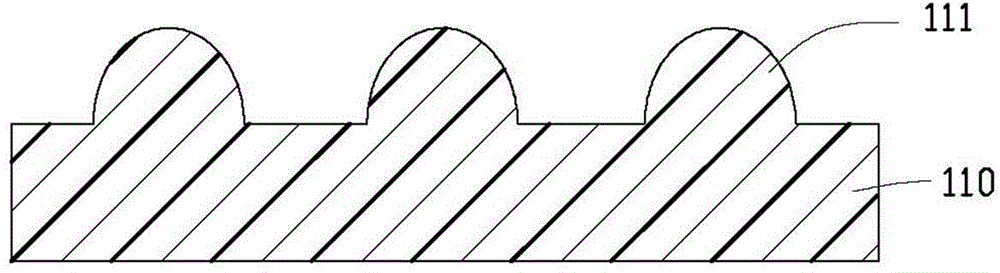

[0033] See figure 1 , first provide a sapphire substrate 110 . The surface of the sapphire substrate 110 has a plurality of protrusions 111 . In this embodiment, the cross section of the protruding portion 111 is semicircular. The cross section of the protruding portion 111 may also be triangular, trapezoidal or other polygonal.

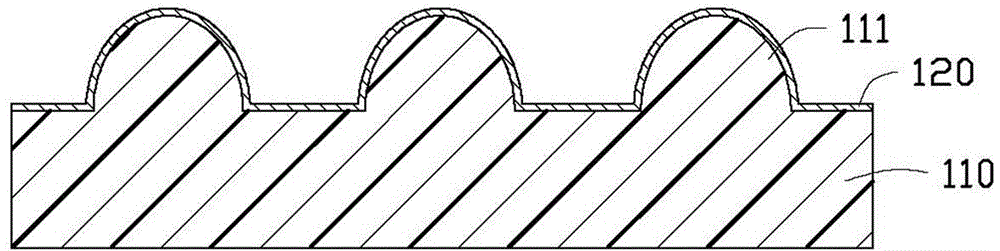

[0034] See figure 2 , grow an undoped low-temperature GaN layer 120 with uniform thickness on the surface of the sapphire substrate 110 and the protruding portion 111 . The thickness of the undoped low-temperature GaN layer 120 is 20-30 nm. The growth temperature of the undoped low temperature GaN layer 120 is 500-600°C. The purpose of growing the undoped low-temperature GaN layer is to grow the subsequent undoped high-temperature GaN layer 121 well.

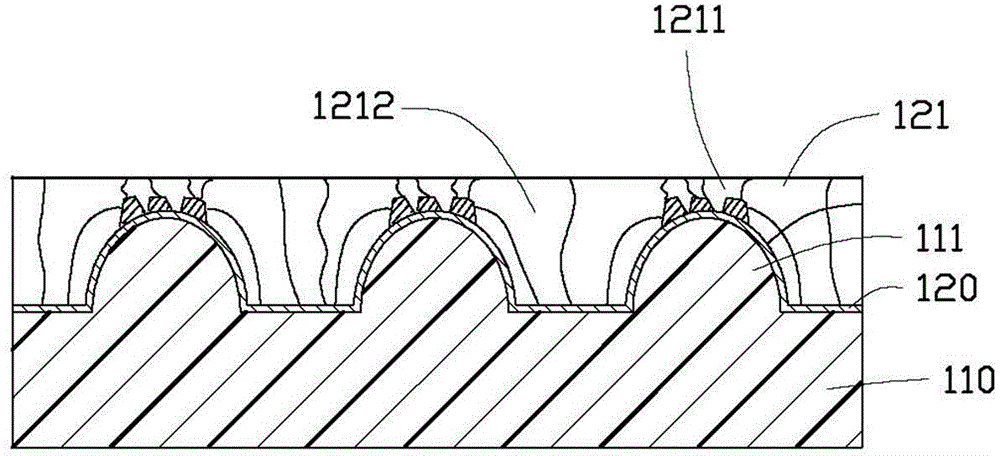

[0035] see image 3 , growing an undoped high temperature GaN layer 121 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com