Method for preparing A12O3 tritium permeation barrier by adopting gas pulse response sputtering method

A gas pulse, sputtering technology, applied in coating, sputtering, metal material coating process, etc., to achieve the effect of strong repeatability, simple process operation and easy phase formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

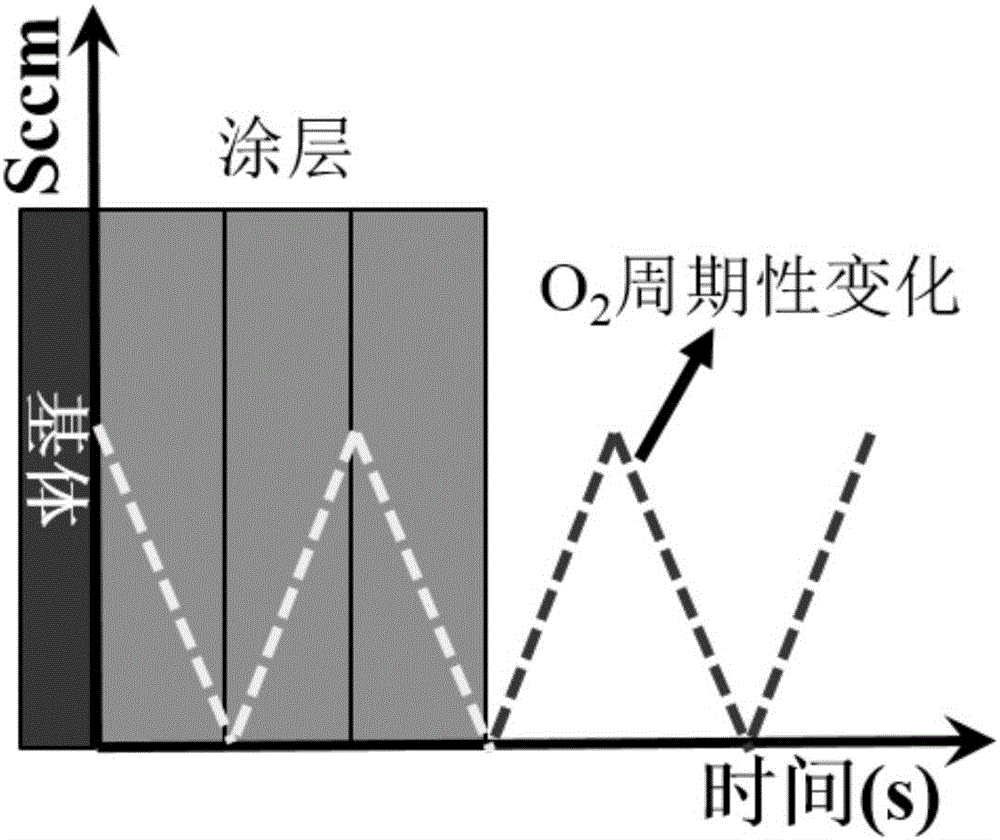

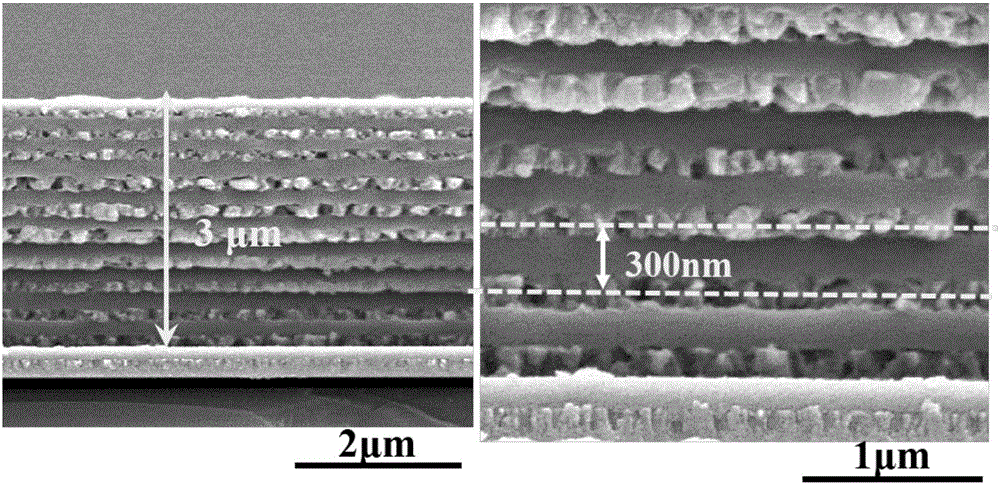

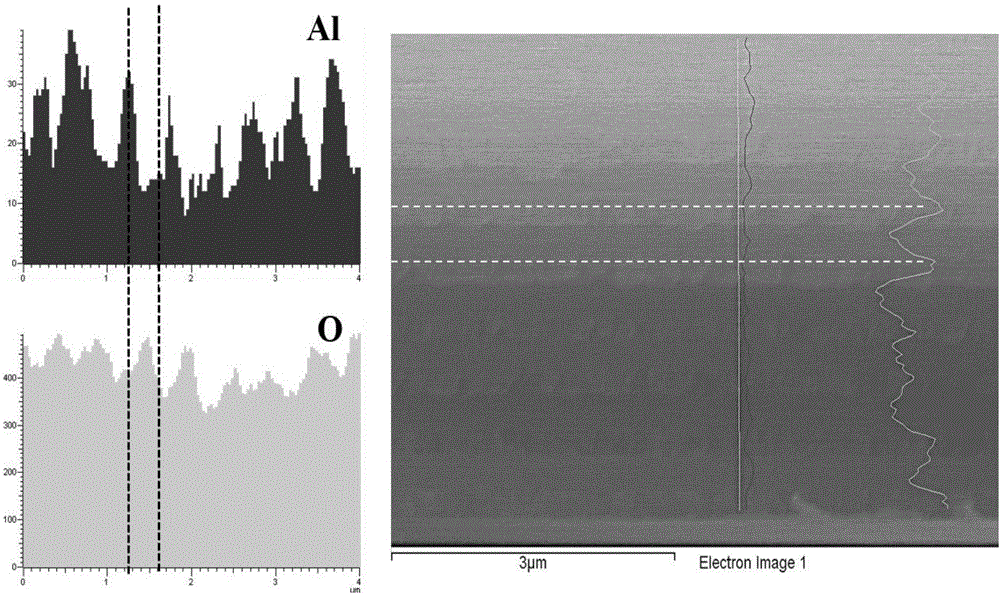

Method used

Image

Examples

Embodiment 1

[0033] (1) Substrate pretreatment

[0034] Use 180#, 240#, 600#, 1000#, 1200# water sandpaper to polish the CLF-1 substrate in sequence from coarse to fine, and then polish it with 1μm diamond polishing agent, W1 polishing powder, W1 polishing paste, and electrolytic polishing , degreasing, pickling, and finally rinsed with deionized water and dried for use; the degreasing agent formula is composed of sodium carbonate 160g / L, sodium citrate 45g / L, active agent 5g / L, sodium phosphate 50g / L .

[0035] (2) Bias backsplash cleaning

[0036] Deflate the vacuum multi-functional magnetron sputtering equipment until the vacuum degree of the vacuum chamber is atmospheric pressure, open the vacuum chamber, place the CLF-1 wafer processed in step (1) on the sample stage of the vacuum chamber, and first pump the vacuum chamber to a low vacuum , after the molecular pump pumps high vacuum to a vacuum degree of 5×10 -4 After Pa, the bias voltage backsplash cleaning, the backsplash bias vo...

Embodiment 2

[0044] (1) Substrate pretreatment

[0045] Use 180#, 240#, 600#, 1000#, 1200# water sandpaper to polish the CLF-1 substrate in turn from coarse to fine, and then polish it with 1μm diamond polishing agent, W1 polishing powder, W1 polishing paste, and electrolytic polishing , degreasing, pickling, and finally rinse with deionized water and dry for use; the degreasing agent formula is composed of sodium carbonate 160g / L, sodium citrate 45g / L, active agent 5g / L, sodium phosphate 50g / L .

[0046] (2) Bias backsplash cleaning

[0047] Deflate the vacuum multi-functional magnetron sputtering equipment until the vacuum degree of the vacuum chamber is atmospheric pressure, open the vacuum chamber, place the CLF-1 wafer processed in step (1) on the sample stage of the vacuum chamber, and first pump the vacuum chamber to a low vacuum , after the molecular pump pumps high vacuum to a vacuum degree of 5×10 -4 After Pa, the bias voltage backsplash cleaning, the backsplash bias voltage i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com