Gallium nitride Schottky barrier diode and manufacturing method thereof

A technology of Schottky potential and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems affecting the efficiency of rectification systems, large reverse leakage current, and insufficient stability of diodes, etc., to achieve Effects of low leakage current, reduced reverse leakage current, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

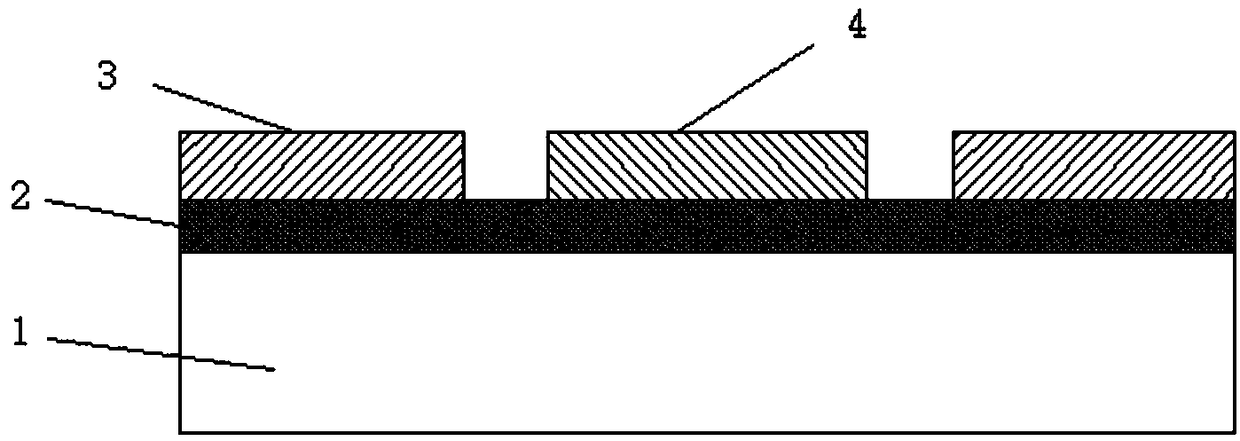

[0024] Such as figure 1 As shown, a gallium nitride Schottky barrier diode provided by the present invention includes a substrate and an epitaxial layer grown on the substrate, and an ohmic electrode and a Schottky electrode are arranged on the epitaxial layer. The Schottky electrode in this example can be circular or any other shape.

[0025] The substrate adopted in the present invention is a sapphire matrix, the epitaxial layer is an n-GaN layer, and the ohmic electrode on the epitaxial layer is a multilayer metal, which is successively titanium / aluminum / titanium / gold from bottom to top, and the titanium layer and The epitaxial layer is contacted, and the ohmic electrode is located at the periphery of the Schottky electrode.

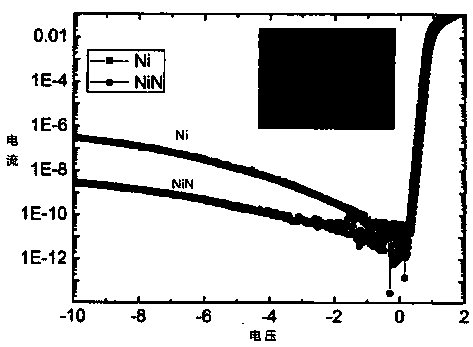

[0026] Wherein, the Schottky electrode includes a nickel nitride thin film layer, and the present invention replaces the nickel metal with the nickel nitride thin film layer as the Schottky contact, which can improve stability and reduce leakage curr...

Embodiment 2

[0037] A Gallium Nitride Schottky barrier diode provided by the present invention includes a substrate and an epitaxial layer grown on the substrate, and an ohmic electrode and a Schottky electrode are arranged on the epitaxial layer. In this embodiment, The Schottky electrode can be circular or any other shape.

[0038] Wherein, the Schottky electrode includes a nickel nitride thin film layer, and the present invention replaces the nickel metal with the nickel nitride thin film layer as the Schottky contact, which can improve stability and reduce leakage current.

[0039] Wherein, the epitaxial layer is an n-GaN layer.

[0040] The present invention also provides a method for manufacturing a Gallium Nitride Schottky barrier diode, comprising the following steps:

[0041] S1: The epitaxial layer of n-GaN is formed on the surface of the substrate by metal organic chemical vapor deposition;

[0042] S2: Use the magnetron sputtering method to sequentially form titanium / aluminum...

Embodiment 3

[0048] A Gallium Nitride Schottky barrier diode provided by the present invention includes a substrate and an epitaxial layer grown on the substrate, and an ohmic electrode and a Schottky electrode are arranged on the epitaxial layer. In this embodiment, The Schottky electrode can be circular or any other shape.

[0049]Wherein, the Schottky electrode includes a nickel nitride thin film layer, and the present invention replaces the nickel metal with the nickel nitride thin film layer as the Schottky contact, which can improve stability and reduce leakage current.

[0050] Wherein, the epitaxial layer is an n-GaN layer.

[0051] The present invention also provides a method for manufacturing a Gallium Nitride Schottky barrier diode, comprising the following steps:

[0052] S1: The epitaxial layer of n-GaN is formed on the surface of the substrate by metal organic chemical vapor deposition;

[0053] S2: Use the magnetron sputtering method to sequentially form titanium / aluminum / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com