Light-induction anti-soil anti-fogging self-cleaning resin glasses lens and preparing method thereof

A resin lens, light-induced technology, applied in optics, optical components, optical components, etc., can solve the problems of inability to use resin lenses, reduce visible light transmittance, and high manufacturing cost of alloy targets, and achieve excellent light-induced anti-fouling and anti-fog. The effect of self-cleaning, excellent anti-reflection performance, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

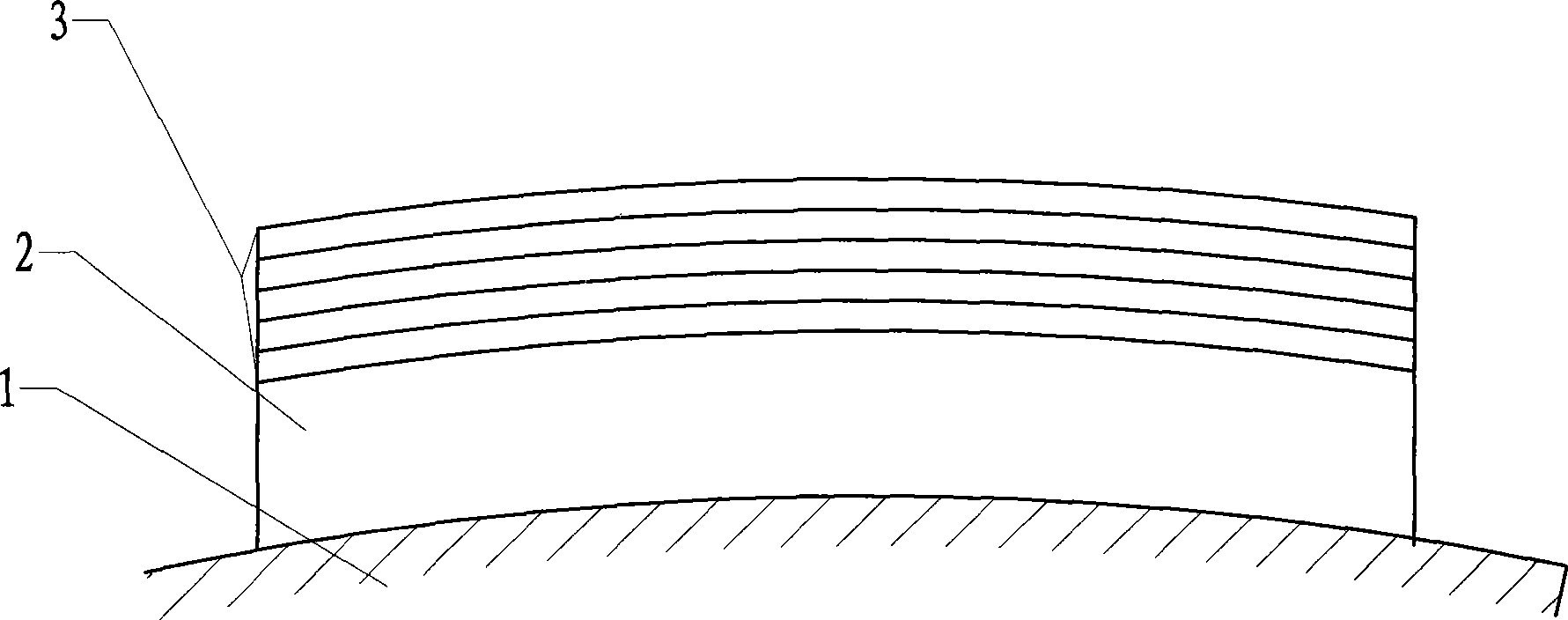

[0022] Embodiments of the present invention are now further described in conjunction with the accompanying drawings:

[0023] As shown in the figure, an embodiment of a light-induced anti-fouling, anti-fog, and self-cleaning resin lens of the present invention includes a resin lens substrate, a hard coat layer formed on the resin lens substrate, and a The anti-reflection film on the film layer, the anti-reflection film is composed of five layers of films, the first to fourth layers of films are respectively TiO 2-x C x Thin film and SiO 2 The thin films are overlapped, and the first layer close to the hard coat layer is TiO 2-x C x film, the outermost film is TiO 2-x-y C x N y film. In the anti-reflection film of this embodiment, the refractive index of the silicon dioxide film layer is 1.46, and the refractive index of the titanium dioxide film layer is 2.3. According to the empirical formula for anti-reflection film design, when the difference between the high and low...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com