Silicon nitride nanoribbon aerogel and preparation method thereof

A silicon nitride and nanobelt technology, applied in ceramic products, other household appliances, applications, etc., can solve the problems of long cycle, low output and high cost, and achieve the effect of increasing growth space and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

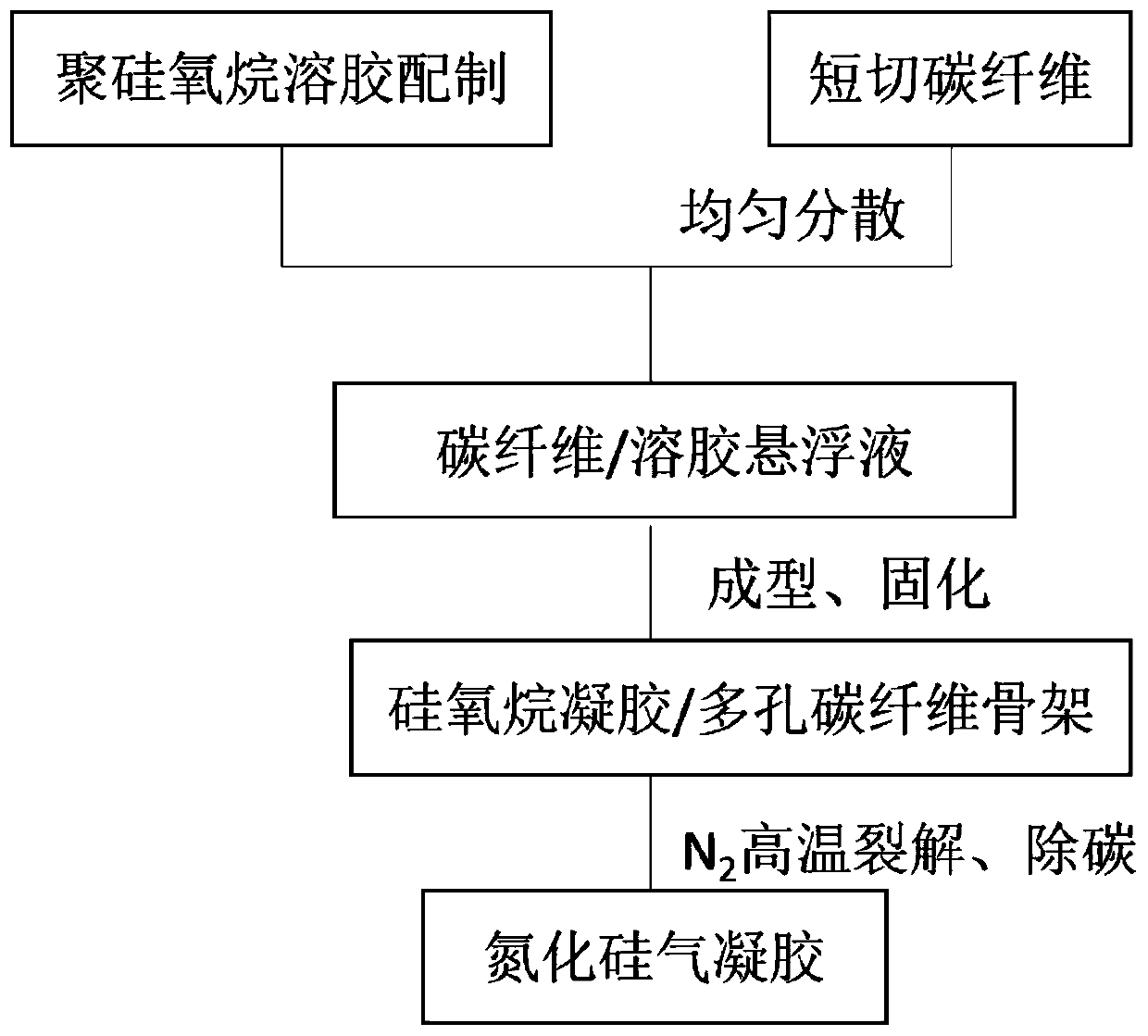

[0035] see figure 1 , is the process flow chart of the preparation method of the silicon nitride nanofiber airgel of the present invention, comprising the following steps:

[0036] 1) Using siloxane precursors, such as methyltrimethoxysilane and dimethyldimethoxysilane, as raw materials, water as a crosslinking agent, and absolute ethanol as a solvent, prepare a polysiloxane sol in a certain proportion;

[0037] 2) uniformly disperse a certain amount of chopped carbon fiber in the polysiloxane sol, so that the surface of the carbon fiber has a layer of siloxane sol;

[0038] 3) Forming: remove most of the silica sol, such as vacuum filtration or pressure filtration, so that the chopped carbon fibers form a three-dimensional porous carbon fiber skeleton bonded by polysiloxane sol;

[0039]4) Curing: place the three-dimensional porous carbon fiber skeleton in an environment of 80°C to 120°C for heat preservation for 4 to 8 hours;

[0040] 5) Cracking: Put the cured carbon fibe...

Embodiment 1

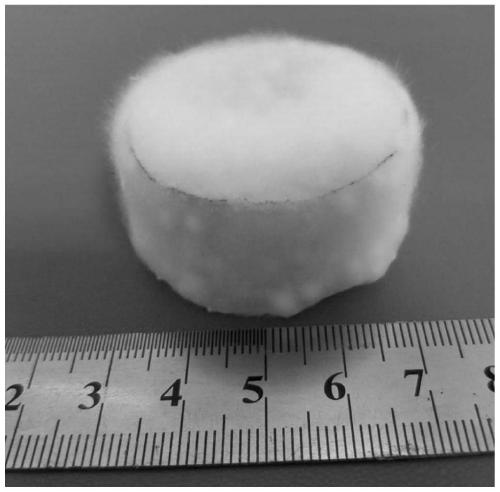

[0043] This embodiment has prepared the density is 5mg / cm 3 , and silicon nitride airgel with adjustable size and density, the specific steps are as follows:

[0044] 1) Prepare silica sol with methyltrimethoxysilane (mass fraction 10wt.%) and silica sol raw materials, water as crosslinking agent (mass fraction 30wt.%) and absolute ethanol as solvent (mass fraction 60wt.%) ;

[0045] 2) Disperse 2g of chopped carbon fibers (about 2mm in length) in 100ml of silica sol, and mechanically stir for 10min;

[0046] 3) The method of vacuum filtration is adopted to overlap the carbon fibers dispersed in the sol to form a three-dimensional porous carbon fiber skeleton;

[0047] 4) The porous carbon fiber skeleton is placed in an environment of 100 ° C, and heat preservation treatment is carried out for 4 hours;

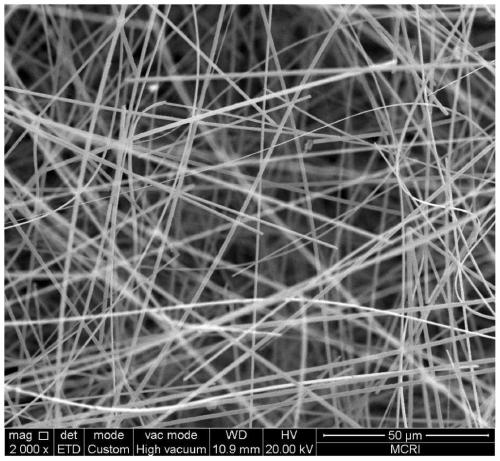

[0048] 5) Raise the temperature to 1400°C in nitrogen with a pressure of 0.2Mpa, heat preservation treatment for 2 hours, and generate a large number of silicon nitride nan...

Embodiment 2

[0053] This embodiment has prepared the density is 15mg / cm 3 , and silicon nitride airgel with adjustable size and density, the specific steps are as follows:

[0054] 1) Using dimethyldimethoxysilane (mass fraction 40wt.%) as raw material, water as crosslinking agent (mass fraction 10wt.%) and absolute ethanol as solvent (mass fraction 50wt.%) to prepare polysilicon Oxygen sol;

[0055] 2) Disperse the chopped carbon fiber (about 1 mm in length) in the silica sol, and perform mechanical stirring for 10 minutes;

[0056] 3) The method of vacuum filtration is adopted to overlap the carbon fibers dispersed in the sol to form a three-dimensional porous carbon fiber skeleton;

[0057] 4) Place the porous carbon fiber skeleton in an oven at 70°C for 8 hours of heat preservation;

[0058] 5) Rise to 1550°C in nitrogen with a pressure of 0.5Mpa, heat preservation treatment for 2 hours, generate a large number of silicon nitride nanofibers in the carbon fiber skeleton, and cool wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com