Porous metal hollow fibrous membrane and preparation method

A porous metal and fiber membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as difficult control of operating conditions, complicated preparation process, low packing density, etc., and achieve brittleness, separation The effect of high efficiency and high packing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Stainless steel powder (316L, d 50 =15μm), 1-methyl-2-pyrrolidone (NMP), polyethersulfone (PES) and water (H 2 O) According to the mass ratio of 0.68:0.2:0.1:0.02, stir continuously and mix evenly. After vacuum defoaming, it is driven by 0.1MPa nitrogen pressure and controlled by a metering pump (25r / min). The 15cm air gap enters the tap water (15°C) tank, deionized water (15°C) is used as the internal coagulation bath, and the flow rate of the internal coagulation bath is controlled at 10ml / min. The obtained hollow fiber body was soaked in water to remove the solvent NMP. After natural air drying, it was sintered under high-purity nitrogen atmosphere. Control the heating rate at 1°C / min to 600°C, hold for 60 minutes, then heat at a rate of 3°C / min to 1050°C, hold for 60 minutes, and finally cool down to room temperature naturally to obtain a porous stainless steel hollow fiber membrane.

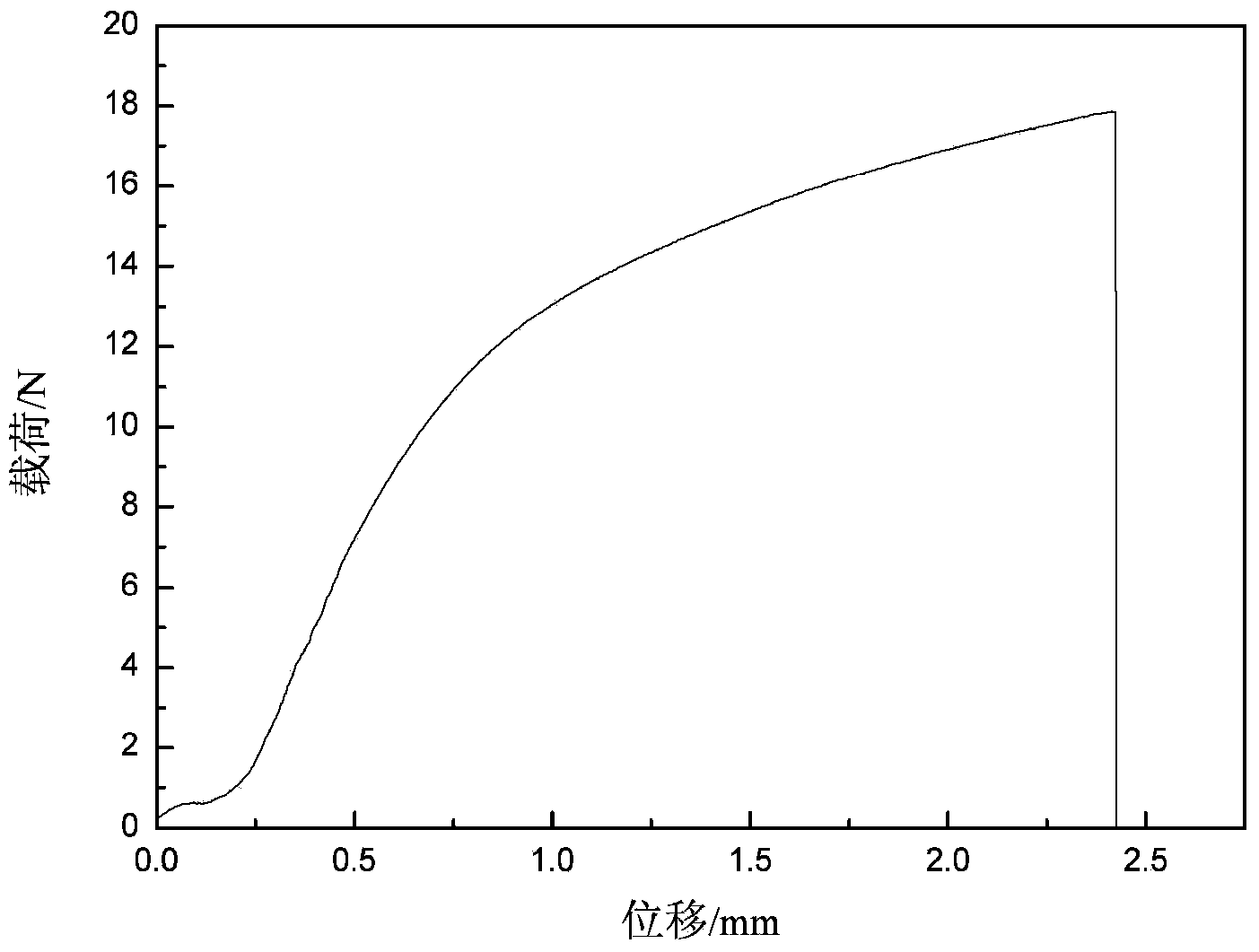

[0027] The hollow fiber membrane prepared by the above process has good tough...

Embodiment 2

[0029] Stainless steel powder (316L, d 50 =6μm), 1-methyl-2-pyrrolidone (NMP), polyethersulfone (PES) and polyvinylpyrrolidone (PVP) according to 0.8:0.15:0.04:0.01. After vacuum defoaming, push the air pressure of 0.15MPa to control the extrusion flow rate of 5ml / min through the metering pump (20r / min). The 10cm air gap enters the tap water (20°C) tank, and the deionized water (20°C) is used as the internal coagulation bath, and its flow rate is controlled at 20ml / min. The obtained hollow fiber body was soaked in water to remove the solvent NMP. After natural air drying, it was sintered under hydrogen atmosphere. Control the heating rate at 3°C / min to 400°C, hold for 120 minutes, then heat to 1150°C at a heating rate of 1°C / min, hold for 120 minutes, and naturally cool to room temperature to obtain a porous stainless steel hollow fiber membrane.

[0030] The outer diameter of the hollow fiber membrane prepared by the above process is 2 mm, the wall thickness is 0.35 mm, an...

Embodiment 3

[0032] Stainless steel powder (316L, d 50=8μm), 1-methyl-2-pyrrolidone (NMP), polyethersulfone (PES) according to the mass ratio of 0.85:0.12:0.03 continuous stirring and mixing. After vacuum defoaming, it is propelled by 0.25MPa nitrogen pressure, and the extrusion flow rate is controlled by a metering pump (5r / min) to 2ml / min, and the hollow fiber blank is extruded from the spinning head (inner diameter / outer diameter is 0.5mm / 1.8mm). The 5cm air gap enters the tap water (25°C) tank, deionized water (25°C) is used as the internal coagulation bath, and its flow rate is controlled at 30ml / min. The obtained hollow fiber body was soaked in water to remove the solvent NMP. After natural air drying, it was sintered in a helium atmosphere. Control the heating rate at 2°C / min to 400°C, hold for 120 minutes, then heat to 1300°C at a rate of 2°C / min, hold for 120 minutes, and finally cool down to room temperature naturally to obtain a porous stainless steel hollow fiber membrane.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com