Three-dimensional printing photosensitive resin material containing solid rubber and preparation method

A solid rubber, 3D printing technology, applied in epoxy resin coatings, rubber derivative coatings, additive processing, etc., can solve problems such as high brittleness, restrictions on the large-scale popularization and application of additive manufacturing technology, aging and yellowing, etc., to achieve The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

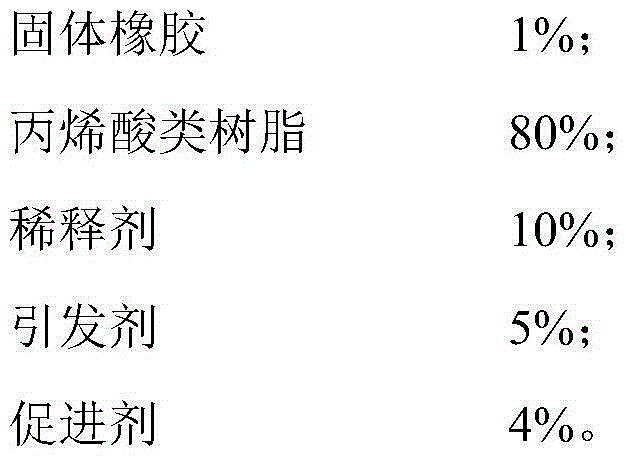

[0022] 1. Proportion according to mass percentage:

[0023]

[0024] 2. Preparation method: a 3D printing photosensitive resin material containing solid rubber, the preparation method of which comprises the following steps:

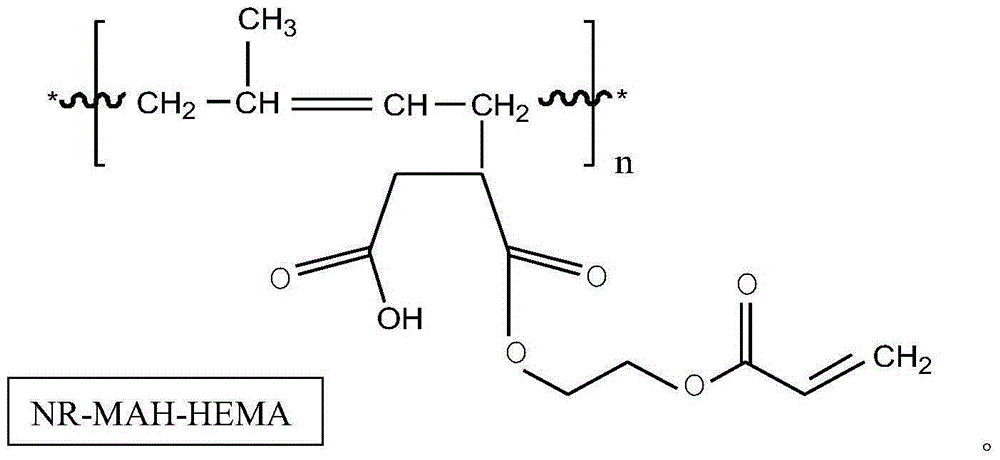

[0025] (1) Preparation of solid rubber: natural rubber mastication, with toluene as solvent, maleic anhydride as graft monomer, described natural rubber: maleic anhydride=(1.5-2.5): 1, temperature is 70-90°C , react for 2h to obtain the grafted product NR-g-MAH; then use triethylenediamine as an initiator to react with hydroxyethyl methacrylate, said hydroxyethyl methacrylate: natural rubber: triethylenediamine=1 : 1: (0.01-0.1), the final product NR-MAH-HEMA was obtained; separated with acetone to obtain a gel-like substance, dried at 60-80°C for 1-2d and taken out; extracted by Soxhlet extractor for 12-48h, Dry at 60-80°C for 1-2 days before use; freeze in liquid nitrogen and grind with a grinder to obtain solid rubber with a size of 300 meshes.

...

Embodiment 2

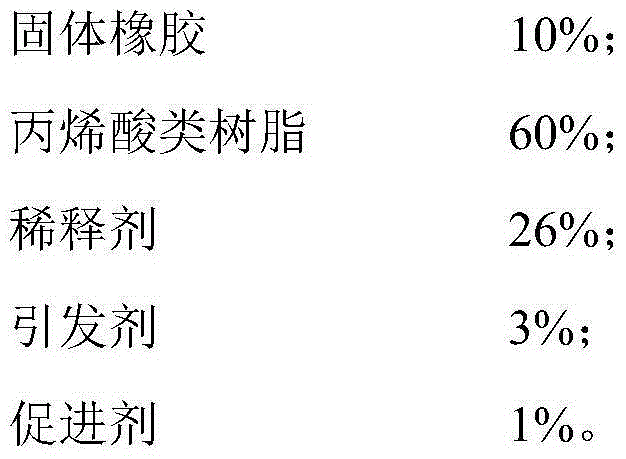

[0029] 1. Proportion according to mass percentage:

[0030]

[0031] 2. Preparation method: a 3D printing photosensitive resin material containing solid rubber, the preparation method of which comprises the following steps:

[0032] (1) The preparation of solid rubber is the same as in Example 1.

[0033] (2) Weigh 10g, 5g, 45g, and 26g of hydroxyl acrylic resin, urethane acrylate resin, epoxy acrylate resin, and trimethylolpropane triacrylate according to the above mass percentage, and weigh solid rubber, UV-369, Each 10g, 3g, 1g of N,N-dimethylaniline was put into the mixer and stirred, the stirring speed was set to 500r / min, and the time was 0.5h. Curing is carried out in a light curing machine, the coating thickness is 1-5μm, the light curing wavelength is 300-400nm, and the curing time is 60s.

[0034] 3. The effect of this embodiment: the universal tensile machine and the impact test are used to test, and the results are as follows: the impact strength is 130J / M, th...

Embodiment 3

[0036] 1. Proportion according to mass percentage:

[0037]

[0038] 2. Preparation method: a 3D printing photosensitive resin material containing solid rubber, the preparation method of which comprises the following steps:

[0039] (1) The preparation of solid rubber is the same as in Example 1.

[0040] (2) Weigh 8g, 11g, 11g, 40g of hydroxyl acrylic resin, polyurethane acrylate resin, epoxy acrylate resin, and styrene according to the above mass percentage, and weigh solid rubber, UV-1173, N,N-dimethyl Each 20g, 5g, 5g of aniline was put into a mixer and stirred, and the stirring speed was set to 500r / min, and the time was 0.5h. After standing without air bubbles, it was coated on the surface-treated iron sheet, and placed in a light curing machine for curing. , the coating thickness is 1-5μm, the photocuring wavelength is 300-400nm, and the curing time is 60s.

[0041] Three, the effect of this embodiment: the universal tensile machine and the impact test are used to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com