High-thermal-conductivity and high-pressure-resistance aluminum-based copper-clad plate and preparation method thereof

An aluminum-based copper-clad laminate, high withstand voltage technology, applied in the field of circuit boards, can solve the problems of lower product qualification rate, easy delamination of sheets, poor bonding force, etc., improve oxidation resistance, have promising development prospects, and solve brittleness problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

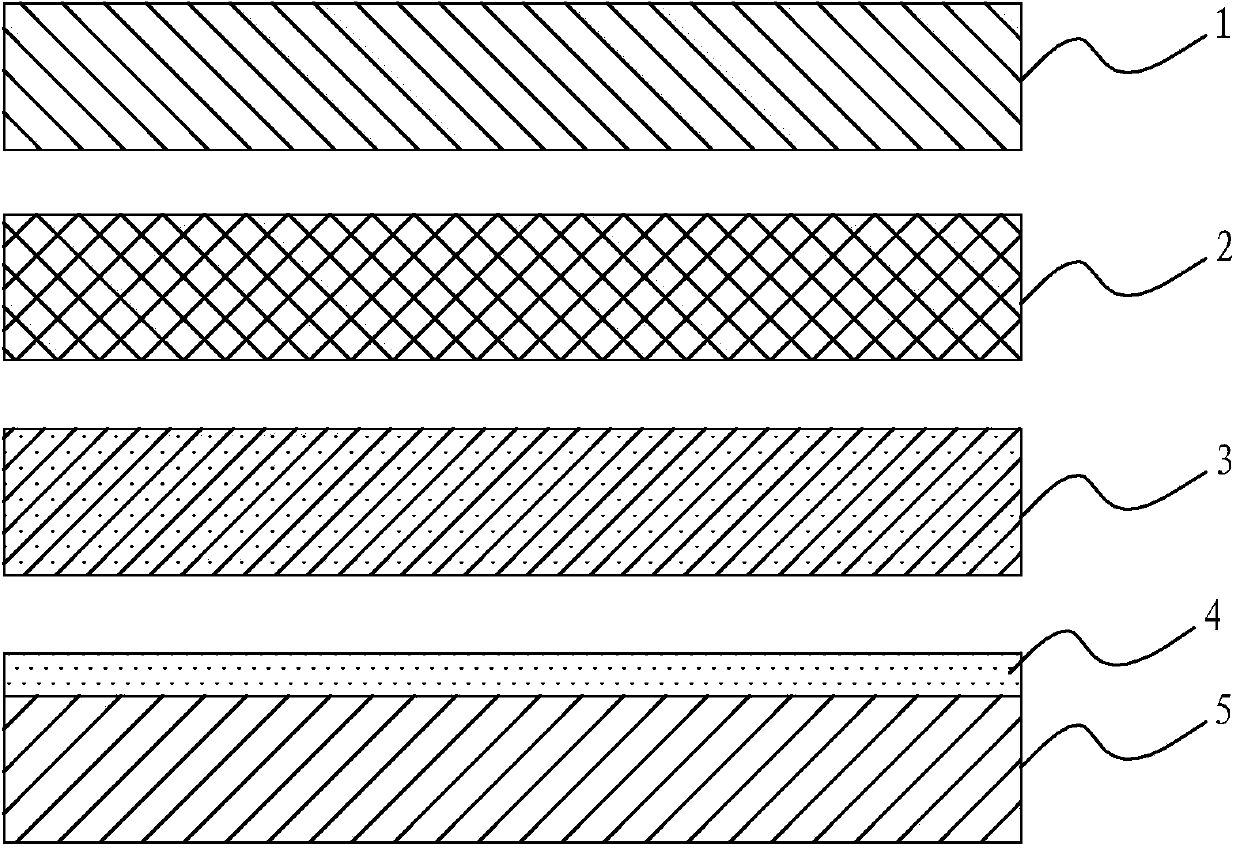

Image

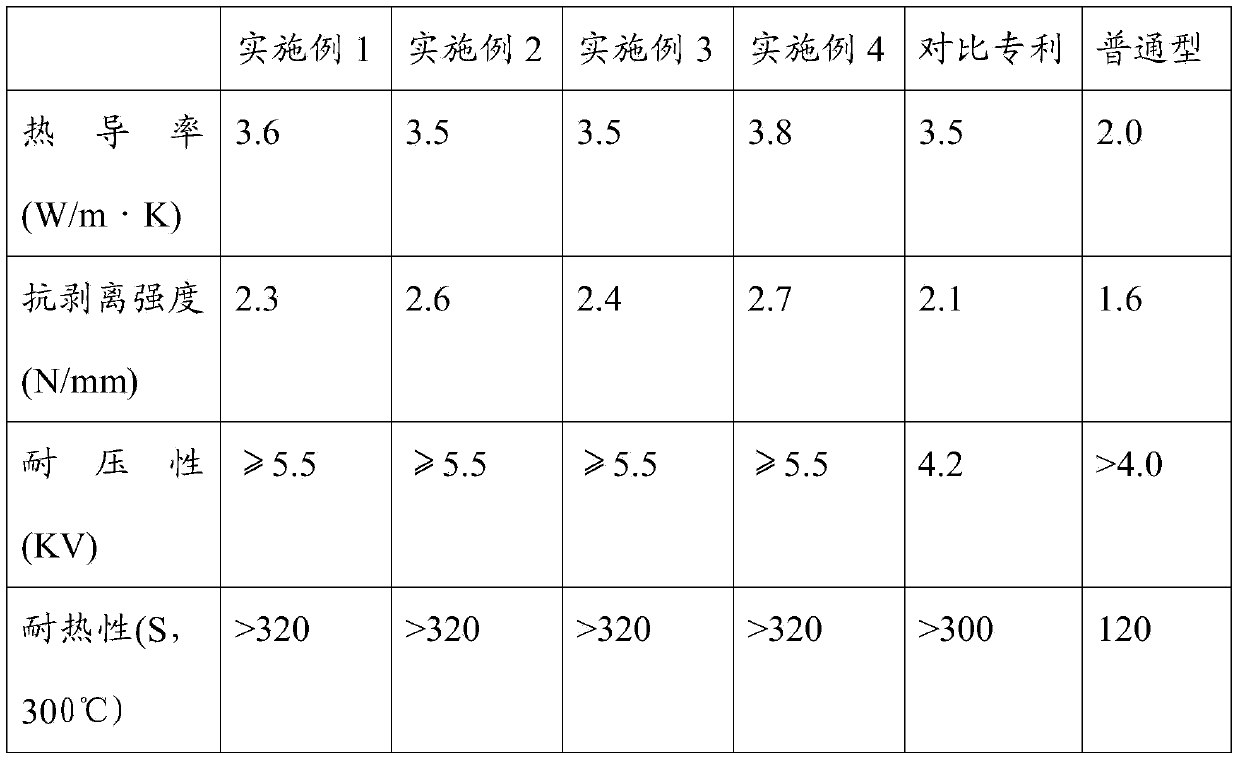

Examples

Embodiment 1

[0034] The components and contents of the insulating and thermally conductive adhesive layer:

[0035] Epoxy resin: 50 parts (resin A: resin B=1:0.6)

[0036] Toughener: 2 parts (phenolic resin: nitrile rubber: acrylic rubber = 5: 2: 1.5)

[0037] Silane coupling agent: 2 parts

[0038] Curing agent: 3.5 parts (phenolic resin: diaminodiphenyl sulfone = 3:1)

[0039] Thermally conductive filler: 45 parts (94% aluminum oxide, 3.2% silicon dioxide, 2.6% silicon carbide)

[0040] The preparation method of the aluminum-based copper-clad laminate: prepare the heat-conducting glue according to the above-mentioned components and content ratio, apply the prepared heat-conducting glue evenly on the release carrier material through the coating machine, and bake the semi-cured film at 70°C. A thermally conductive adhesive film is formed; the surface layer of the aluminum plate is anodized to obtain a uniform and dense oxide film; the adhesive layer, the insulating thermally conductive ...

Embodiment 2

[0042] The components and contents of the insulating and thermally conductive adhesive layer:

[0043] Epoxy resin: 70 parts (resin A: resin B=1:0.6)

[0044] Toughener: 5 parts (phenolic resin: nitrile rubber: polyurethane=4:3:2.5)

[0045] Silane coupling agent: 1 part

[0046] Curing agent: 6 parts (ie diaminodiphenyl sulfone)

[0047]Thermally conductive filler: 30 parts (98% aluminum oxide, 1% silicon dioxide, 0.2% silicon carbide, 0.8% magnesium oxide)

[0048] The preparation method of the aluminum-based copper-clad laminate: prepare a heat-conducting adhesive solution according to the above-mentioned components and content ratios, bake and semi-cure at 60°C to form a heat-conducting adhesive film, and heat-press at 200°C. The rest of the preparation process is the same as in Example 1.

Embodiment 3

[0050] The components and contents of the insulating and thermally conductive adhesive layer:

[0051] Epoxy resin: 40 parts

[0052] Toughener: 3 parts (nitrile rubber: acrylic rubber = 2: 1.5)

[0053] Silane coupling agent: 3 parts

[0054] Curing agent: 3 parts (ie diaminodiphenylamine)

[0055] Thermally conductive filler: 40 parts (63% aluminum oxide, 10% silicon dioxide, 5% silicon carbide, 20% aluminum nitride, and 2% magnesium oxide)

[0056] The preparation method of the aluminum-based copper-clad laminate: prepare a heat-conducting adhesive solution according to the above-mentioned components and content ratios, bake and semi-cure at 80°C to form a heat-conducting adhesive film, and heat-press at 220°C. The rest of the preparation process is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com