Cold working process for high Cr ferrite stainless steel seamless pipe

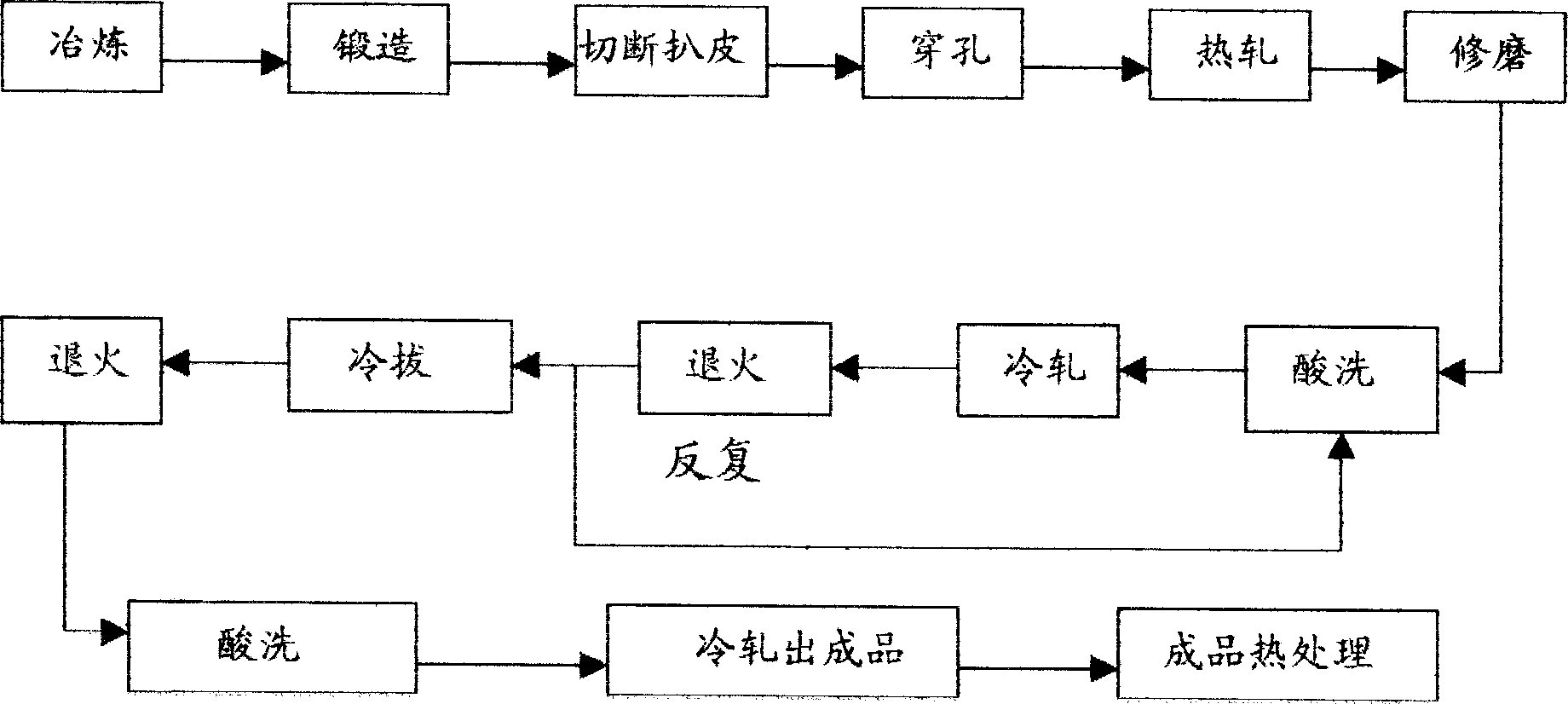

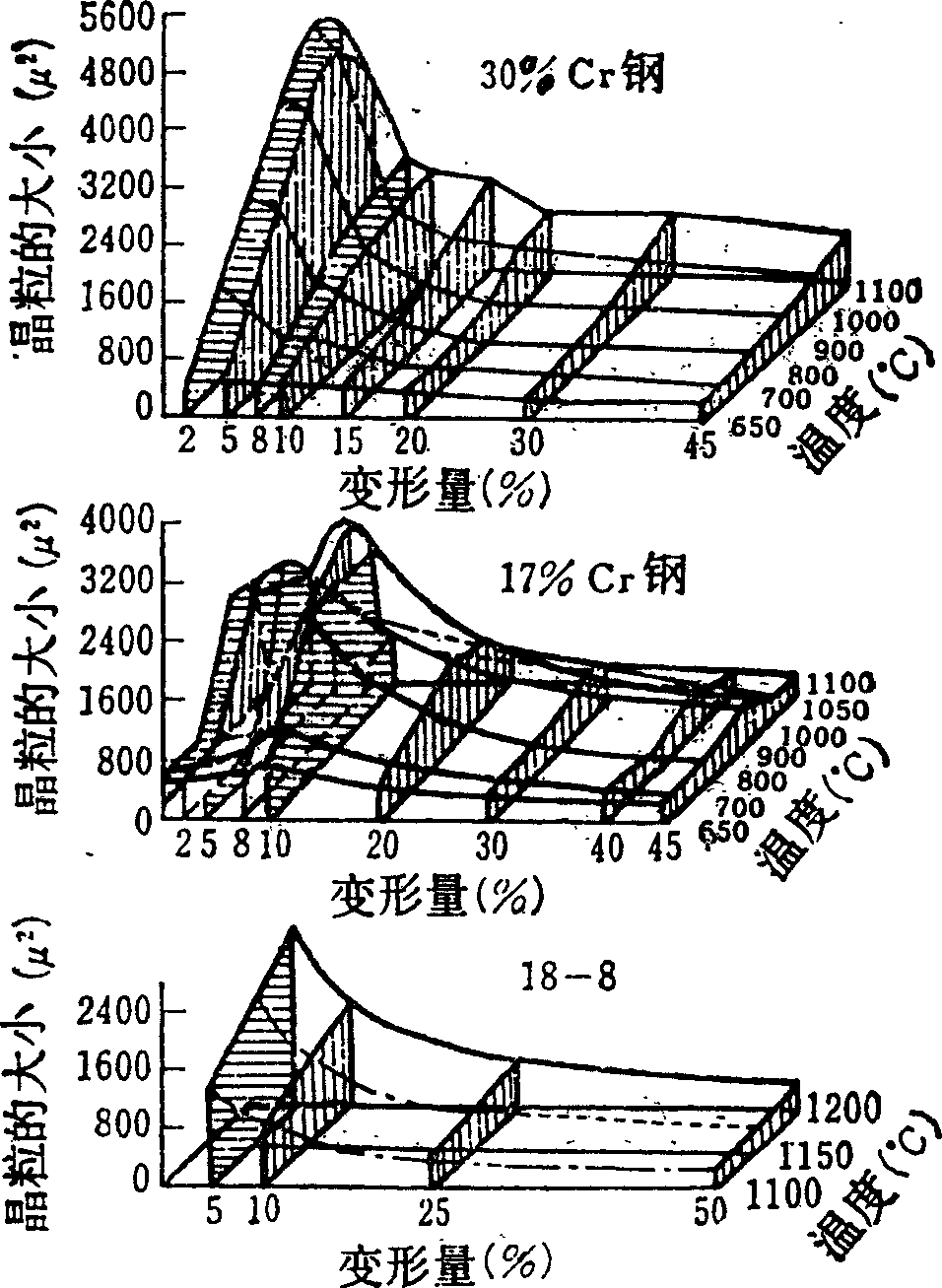

A high-chromium ferrite and stainless steel technology, which is used in the manufacture of ferritic stainless steel pipes and the cold working field of ferritic stainless steel seamless pipes, can solve the problems of low yield of deep processing and inability to solve the cracks on the inner and outer surfaces of steel pipes, etc. Significant technological progress, avoidance of intergranular corrosion problems, effect of significant economic significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with preferred embodiments, the specific implementation, features and effects provided by the present invention are described in detail as follows; for the purpose of simplicity and clarity, the description of known technologies is appropriately omitted below to avoid unnecessary details Affect the description of this technical solution.

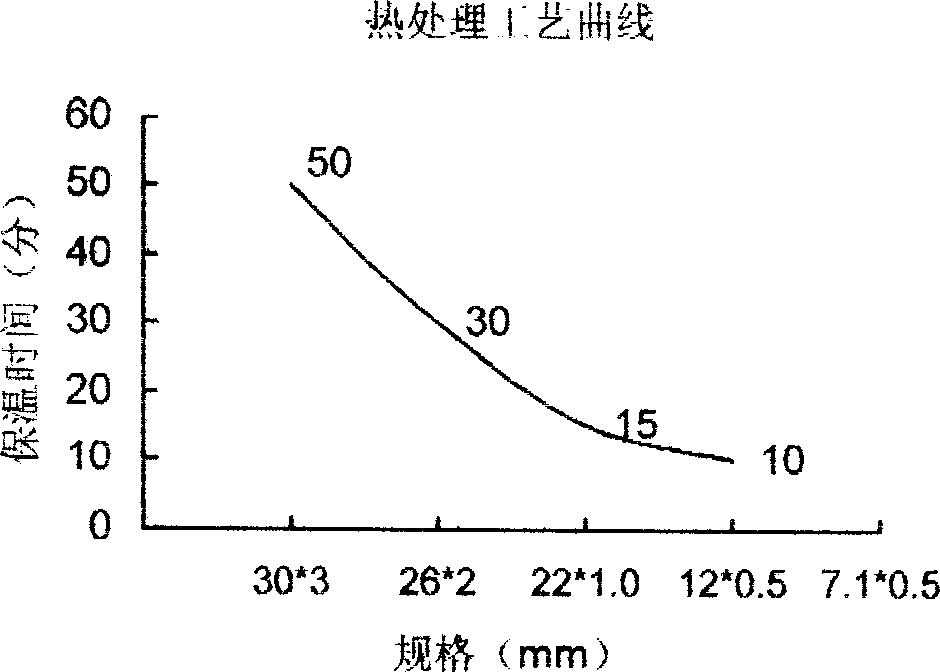

[0039] Manufacture an AISI446 ferritic stainless steel seamless pipe, the specification is Φ6.3×0.3mm, the outer diameter is ±0.1mm, the wall thickness is 0.3-0.35mm, and the length is 58.5±0.1mm; performance requirements: HV<200 during deep processing Cracks are not allowed, and the extension after processing is consistent.

[0040] First, provide eligible steel ingots, where,

[0041] The chemical composition of the steel ingot meets: carbon C≤0.12%; silicon Si<1.0%; manganese Mn≤0.8%; sulfur S≤0.03%; phosphorus P<0.0035%; Fe, 5c is 5 times the carbon content, and the chromium Cr content is controlled in the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com