Thermal-insulating anti-flaming building material and preparation method thereof

A technology of building materials and inorganic gelling materials, which is applied in the field of building materials with thermal insulation and flame retardant functions and its preparation, can solve the problems of easy brittleness and low thermal insulation effect, and achieve the solution of easy brittleness, enhanced thermal insulation effect, and combination tight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

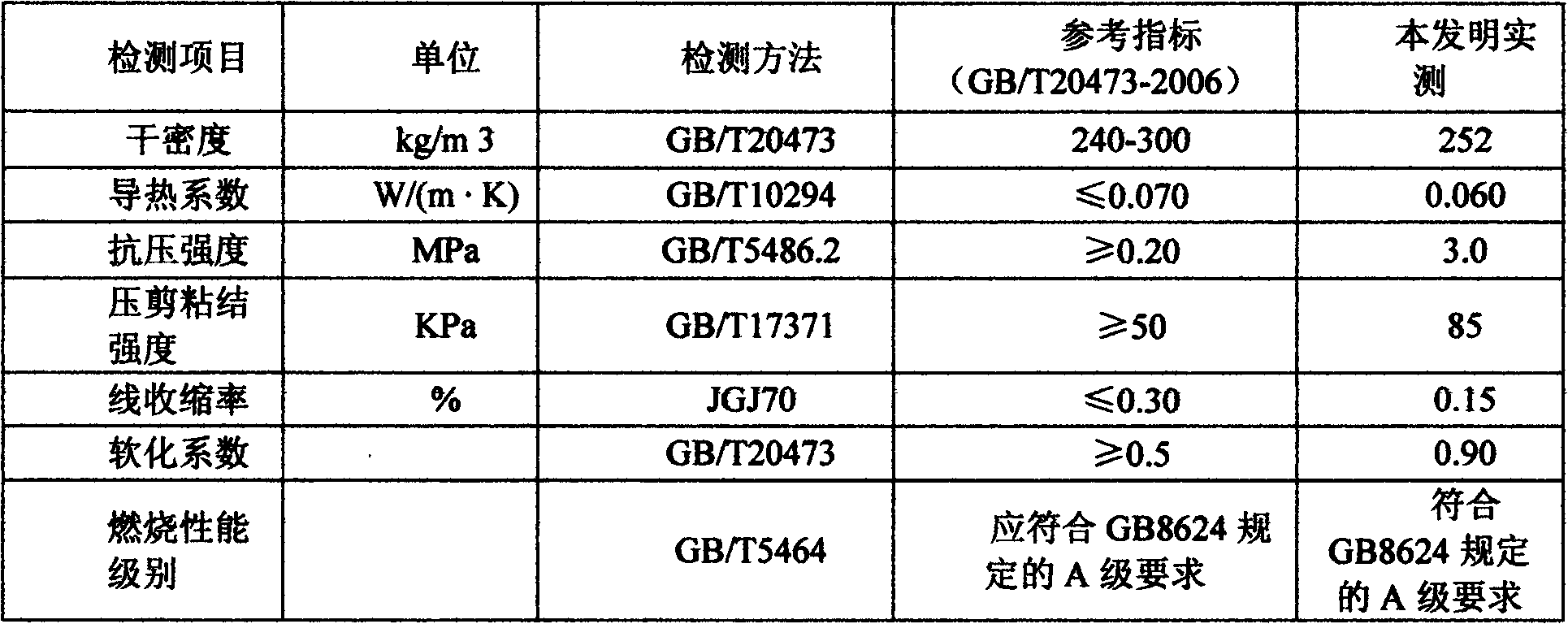

Embodiment 1

[0037] 1) Add 50kg of expanded vermiculite, 4.2kg of bentonite, 2.1kg of magnesite cementitious material, and 0.14kg of active silicon powder into a horizontal rotary mixer with a stirring speed of 50rpm, spray 0.15kg while stirring, and stir for 5 minutes, as spare material;

[0038] 2) Add 45kg of 425# Portland cement, 4kg of potassium carbonate whiskers, and 2kg of calcium sulfate whiskers to a two-axis gravity-free mixer with a stirring speed of 300rpm and a stirring time of 5 minutes;

[0039]3) Add 1kg of the modified lightweight aggregate and dispersing aid in step 1) to step 2), the stirring speed is 100rpm, and stir for 3 minutes;

[0040] 4) Discharging, weighing, and packaging the mixture obtained in step 3) to obtain a heat-insulating and flame-retardant building material.

[0041] Mix and stir the thermal insulation and flame retardant building material with water at a ratio of 1:0.85-1 until it becomes a uniform paste, then it can be used. The slurry is ready-t...

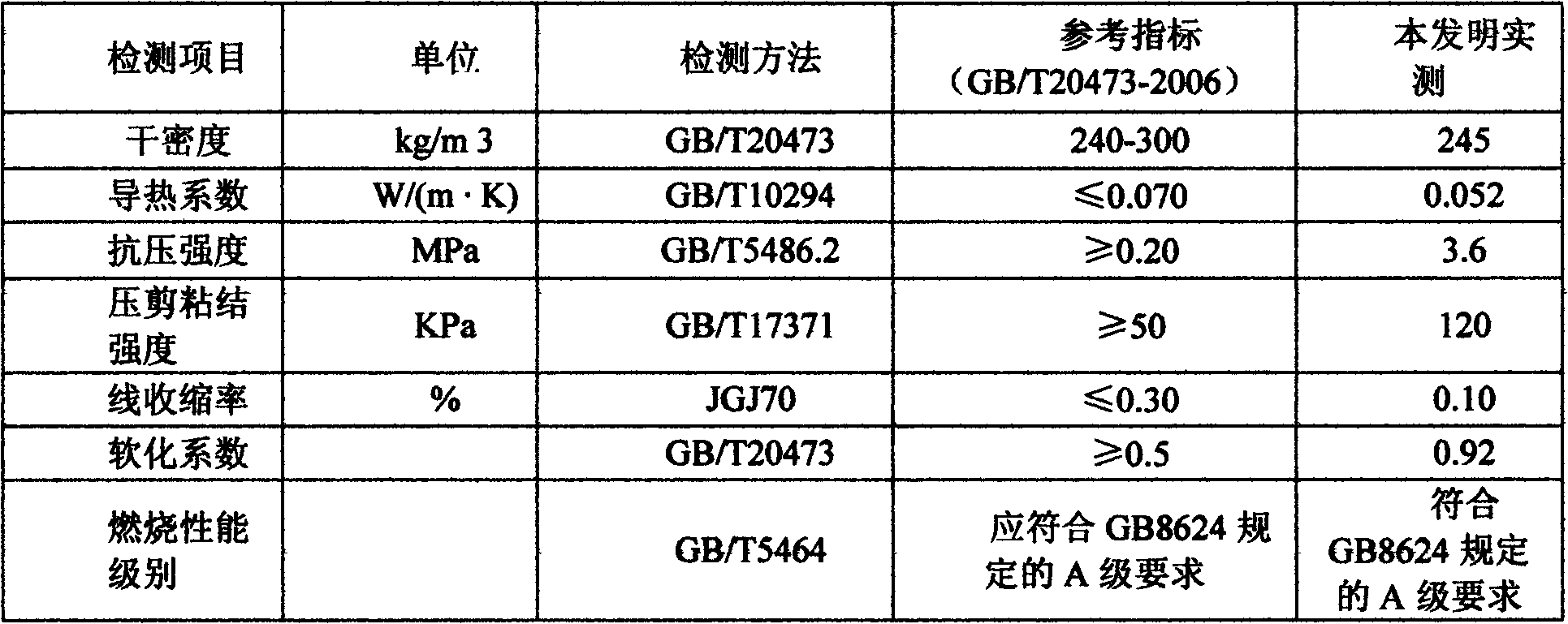

Embodiment 2

[0045] 1) Add 20kg of fly ash, 30kg of diatomaceous earth, 3kg of magnesium silicate, 1.5kg of high alumina cementitious material, and 0.15kg of alum stone into a horizontal rotary mixer with a stirring speed of 80rpm, and spray 0.2kg of water while stirring, Stirring time is 5 minutes, as a spare material;

[0046] 2) Add 45kg of sulfoaluminate cement, 5kg of calcium carbonate whiskers, and 3kg of magnesium salt whiskers into a two-axis gravity-free mixer with a stirring speed of 400rpm and a stirring time of 5 minutes;

[0047] 3) Add 0.5 kg of the modified lightweight aggregate and dispersing aid in step 1) to step 2), at a stirring speed of 50 rpm, and stir for 4 minutes;

[0048] 4) Discharging, weighing, and packaging the mixture obtained in step 3) to obtain a heat-insulating and flame-retardant building material.

[0049] Mix and stir the heat-insulating and flame-retardant building material with water at a ratio of 1:0.75-0.90 until it is uniformly paste-like, and th...

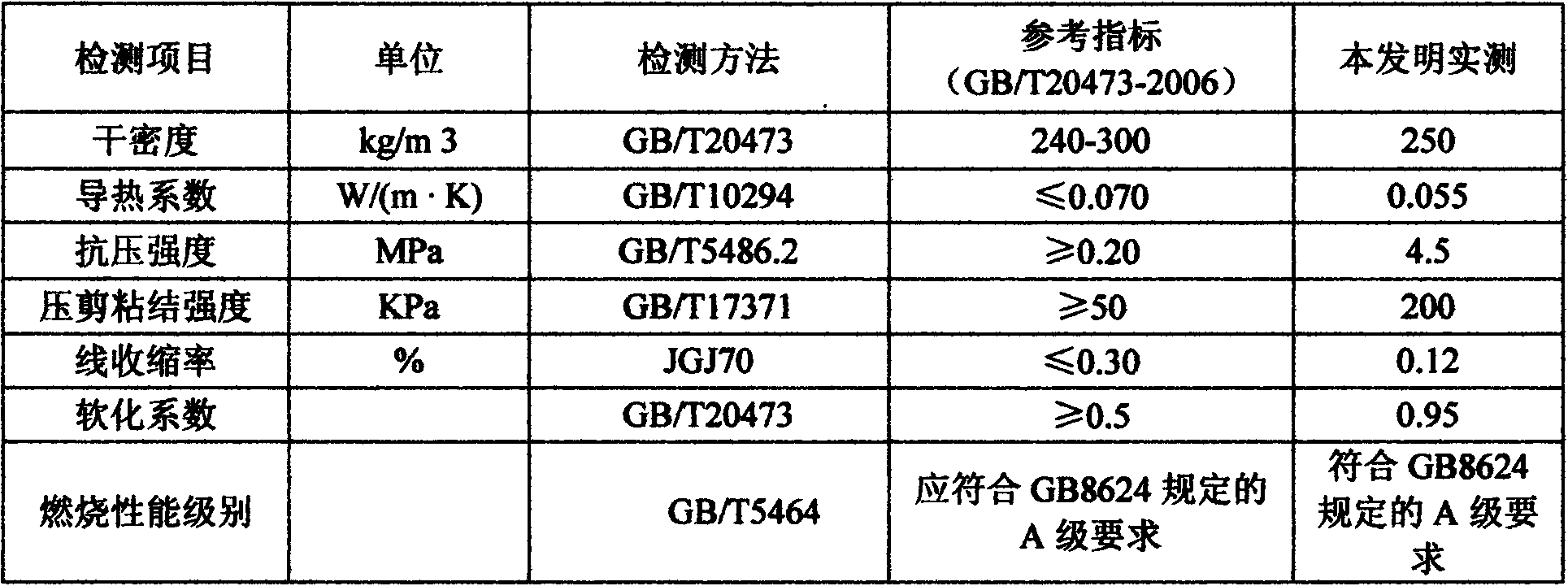

Embodiment 3

[0053] 1) Add 20kg of floating beads 25 expanded perlite, 1.5kg of mica powder, 1.5kg of bentonite, 1.5kg of high alumina cementitious material, and 0.1kg of magnesium chloride into a horizontal rotary mixer with a stirring speed of 50rpm, and spray 0.2kg of water while stirring , stirring for 5 minutes, as a spare material;

[0054] 2) Add 45kg of aluminate cement, 3kg of potassium carbonate whiskers, and 3kg of magnesium salt whiskers into a two-axis gravity-free mixer with a stirring speed of 400rpm and a stirring time of 5 minutes;

[0055] 3) Add 0.8 kg of the modified lightweight aggregate and dispersing aid in step 1) to step 2), at a stirring speed of 50 rpm, and stir for 5 minutes;

[0056] 4) Discharging, weighing, and packaging the mixture obtained in step 3) to obtain a heat-insulating and flame-retardant building material.

[0057] Mix and stir the thermal insulation and flame retardant building material with water at a ratio of 1:1 until it becomes a uniform pas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com