Total heat exchange graphene paper film

A graphene paper, full heat exchange technology, applied in paper, papermaking, papermaking and other directions, can solve problems such as reducing air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

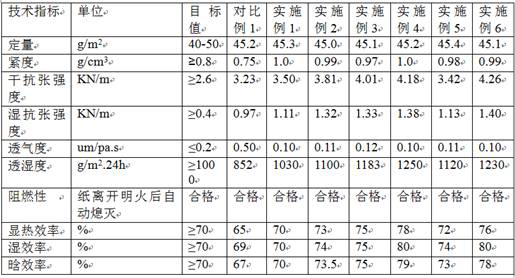

Examples

Embodiment 1

[0040] A preparation method for a total heat exchange graphene paper film, comprising the following steps:

[0041] 1) Base paper making: 70% softwood pulp + 30% hardwood pulp is used as raw material, the beating degree of the mixed pulp is 45°SR, and the graphene water-based slurry with a relative absolute dry fiber content of 0.5% is added to the slurry. The urea-formaldehyde resin with an absolute dry fiber content of 2.0% and the cationic starch with a relative absolute dry fiber content of 2% are prepared on a fourdrinier paper machine with water as a medium to obtain base paper at a speed of 100 m / min;

[0042] The graphene water-based slurry: the active ingredient content is 11±1%, and the viscosity is 2000±200mpa.s.

[0043] 2) Preparation of surface sizing solution: prepare polyvinyl alcohol and nitrogen-based flame retardant in a ratio of 1:4 to prepare a glue solution with a concentration of 18%, add pyrimidine antibacterial agents for mixing, and the amount of pyri...

Embodiment 2

[0048] A kind of production method of total heat exchange graphene paper film, comprises the following steps:

[0049] 1) Base paper making: 70% softwood pulp + 30% hardwood pulp is used as raw material, the beating degree of the mixed pulp is 50°SR, and the graphene water-based slurry with a relative dry fiber content of 1% is added to the slurry. The absolute dry fiber content is 0.6% sodium carboxymethyl cellulose and the relative absolute dry fiber content is 2% polyamide epichlorohydrin resin, and water is used as medium to carry out papermaking on a cylinder paper machine to obtain base paper, and the vehicle speed is 100m / min;

[0050] The graphene water-based slurry: the active ingredient content is 11±1%, and the viscosity is 2000±200mpa.s.

[0051] 2) Preparation of surface sizing solution: Prepare starch and brominated flame retardant in a ratio of 1:4 to prepare a glue solution with a concentration of 15%, and add ammonium compounds to mix; the amount of ammonium...

Embodiment 3

[0056] A kind of production method of total heat exchange graphene paper film, comprises the following steps:

[0057] 1) Base paper making: 70% coniferous wood pulp + 30% hardwood pulp is used as raw material, the beating degree of the mixed pulp is 55°SR, and the graphene water-based slurry with a relative dry fiber content of 1.5% is added to the slurry. The absolute dry fiber content is 0.7% sodium carboxymethyl cellulose and the relative absolute dry fiber content is 2% polyamide epichlorohydrin resin, with water as the medium, papermaking is carried out on the fourdrinier paper machine to obtain the base paper, and the speed of the machine is 100m / min;

[0058] The graphene water-based slurry: the active ingredient content is 11±1%, and the viscosity is 2000±200mpa.s.

[0059] 2) Preparation of surface sizing solution: prepare polyvinyl alcohol and phosphorus flame retardant at a ratio of 1:5 to prepare a glue solution with a concentration of 16%, add organic bromine c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com