Production method of total heat exchange graphene paper film

A graphene paper and total heat exchange technology, applied in paper, papermaking, paper coating, etc., can solve the problems of not being able to simultaneously improve sensible heat exchange efficiency, air permeability, moisture permeability, humidity efficiency and Han efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

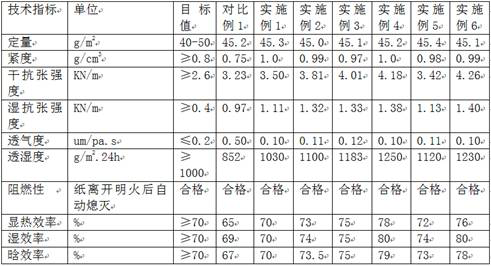

Examples

Embodiment 1

[0035] A kind of production method of total heat exchange graphene paper film, comprises the following steps:

[0036] 1) Base paper making: 70% softwood pulp + 30% hardwood pulp is used as raw material, the beating degree of the mixed pulp is 45°SR, and the graphene water-based slurry with a relative absolute dry fiber content of 0.5% is added to the slurry. The urea-formaldehyde resin with an absolute dry fiber content of 2.0% and the cationic starch with a relative absolute dry fiber content of 2% are prepared on a fourdrinier paper machine with water as a medium to obtain base paper at a speed of 100 m / min;

[0037] The graphene water-based slurry: the active ingredient content is 11±1%, and the viscosity is 2000±200mpa.s.

[0038] 2) Preparation of surface sizing solution: prepare polyvinyl alcohol and nitrogen-based flame retardant in a ratio of 1:4 to prepare a glue solution with a concentration of 18%, add pyrimidine antibacterial agents for mixing, and the amount of p...

Embodiment 2

[0043] A kind of production method of total heat exchange graphene paper film, comprises the following steps:

[0044] 1) Base paper making: 70% softwood pulp + 30% hardwood pulp is used as raw material, the beating degree of the mixed pulp is 50°SR, and the graphene water-based slurry with a relative dry fiber content of 1% is added to the slurry. The absolute dry fiber content is 0.6% sodium carboxymethyl cellulose and the relative absolute dry fiber content is 2% polyamide epichlorohydrin resin, and water is used as medium to carry out papermaking on a cylinder paper machine to obtain base paper, and the vehicle speed is 100m / min;

[0045] The graphene water-based slurry: the active ingredient content is 11±1%, and the viscosity is 2000±200mpa.s.

[0046] 2) Preparation of surface sizing solution: Prepare starch and brominated flame retardant in a ratio of 1:4 to prepare a glue solution with a concentration of 15%, and add ammonium compounds to mix; the amount of ammonium...

Embodiment 3

[0051] A kind of production method of total heat exchange graphene paper film, comprises the following steps:

[0052] 1) Base paper making: 70% coniferous wood pulp + 30% hardwood pulp is used as raw material, the beating degree of the mixed pulp is 55°SR, and the graphene water-based slurry with a relative dry fiber content of 1.5% is added to the slurry. The absolute dry fiber content is 0.7% sodium carboxymethyl cellulose and the relative absolute dry fiber content is 2% polyamide epichlorohydrin resin, with water as the medium, papermaking is carried out on the fourdrinier paper machine to obtain the base paper, and the speed of the machine is 100m / min;

[0053] The graphene water-based slurry: the active ingredient content is 11±1%, and the viscosity is 2000±200mpa.s.

[0054] 2) Preparation of surface sizing solution: prepare polyvinyl alcohol and phosphorus flame retardant at a ratio of 1:5 to prepare a glue solution with a concentration of 16%, add organic bromine c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com