Modified chitosan fiber and polylactic acid composite material and preparation method thereof

A technology of chitosan fiber and composite material, which is applied in the field of preparation of biomedical composite materials, can solve the problems of inability to maintain the fiber shape and destroy the fiber structure, avoid side effects and pollution, have strong interfacial adhesion, and improve the interfacial phase. capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

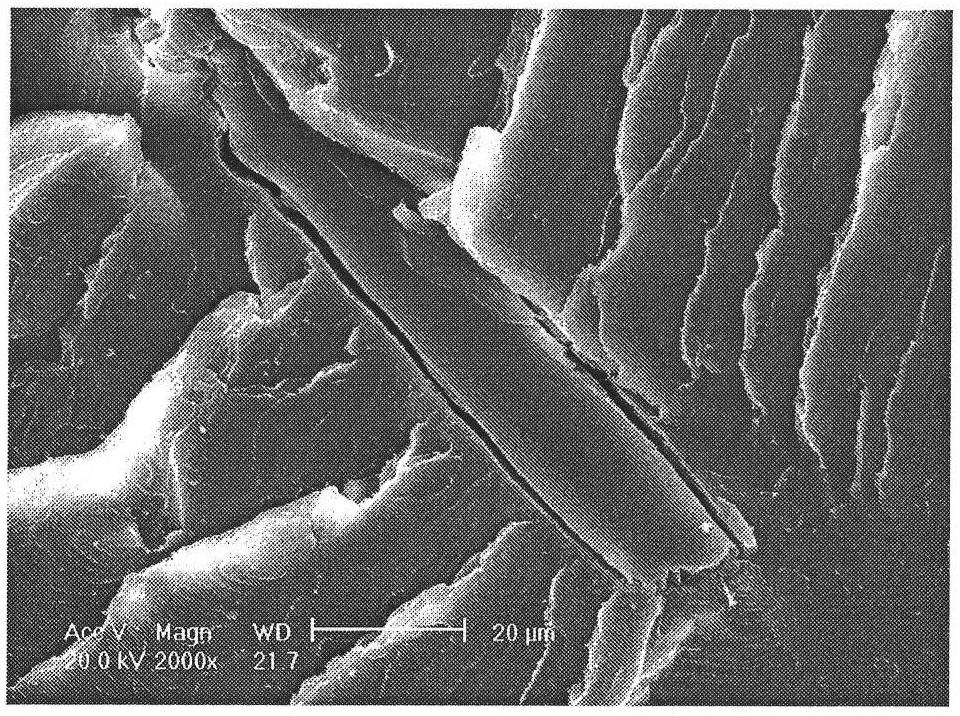

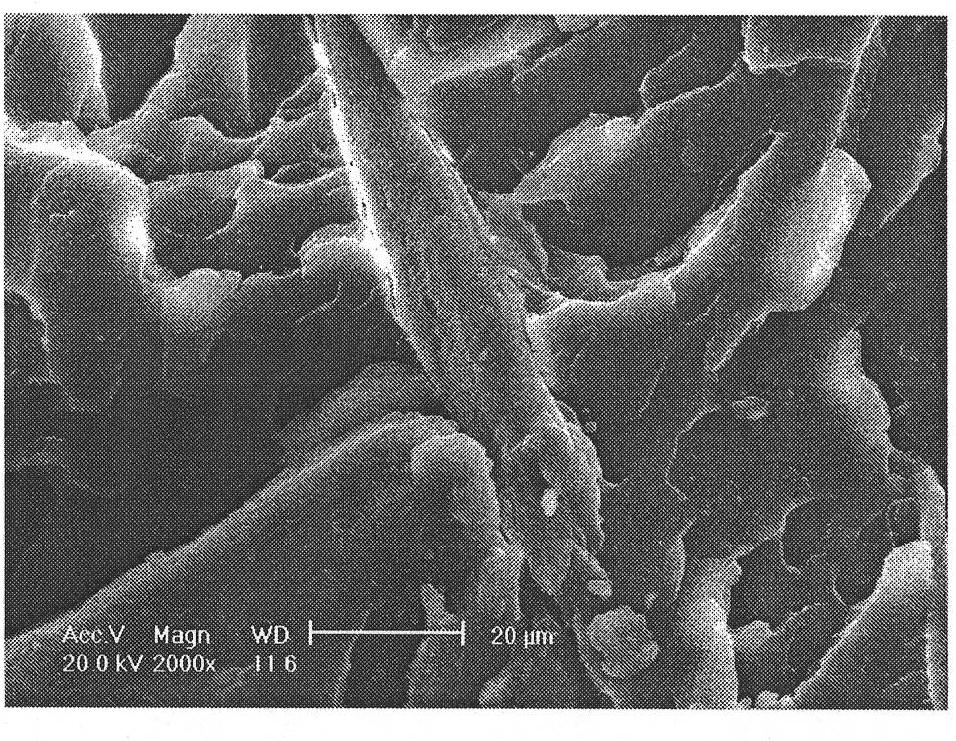

Image

Examples

Embodiment 1

[0019] The mass fraction is 0.01%, 0.1%, 0.5% polylactic acid dissolved in the mixed solution of dilute acetic acid and dioxane (volume ratio is 1:9), and the mass fraction of 5% chitosan fiber is put into it Swell, after 10min, add absolute ethanol, take out the chitosan fiber, vacuum dry. The resulting rejection rates were 11.81%, 12.83%, and 12.86%, respectively.

Embodiment 2

[0021] The molecular weight is 2500, 1×10 4 , 1×10 5 Polylactic acid was dissolved in a mixed solution of dilute acetic acid and dioxane (volume ratio 1:9), chitosan fibers with a mass fraction of 5% were put into it for swelling, after 10 min, absolute ethanol was added, and the chitosan fibers were taken out. Sugar fiber, vacuum dried. The resulting rejection rates were 11.81%, 11.70%, and 11.57%, respectively.

Embodiment 3

[0023] The mass fraction is 0.1% polylactic acid is dissolved in the mixed solution (volume ratio is 1:9) of dilute acetic acid and dioxane, the chitosan fiber that mass fraction is 5% is put into it and swells, and time is respectively set at 2min , 5min, 10min, 20min, add absolute ethanol, take out the chitosan fiber, and vacuum dry. The rejection rate is 11.31%, 11.57%, 12.81%, 12.98%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com