Unidirectional heat transfer flame retardation PTC macromolecule self-limiting temperature electrothermal film and preparation method thereof

A technology of polymer and electric heating film, which is used in electric heating devices, electrical components, ohmic resistance heating, etc., can solve the problems of small cracks in the conductive film layer, potential safety hazards, and detachment of the conductive film layer, and achieve unidirectional heat transfer. Good, improve the performance stability, prolong the service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

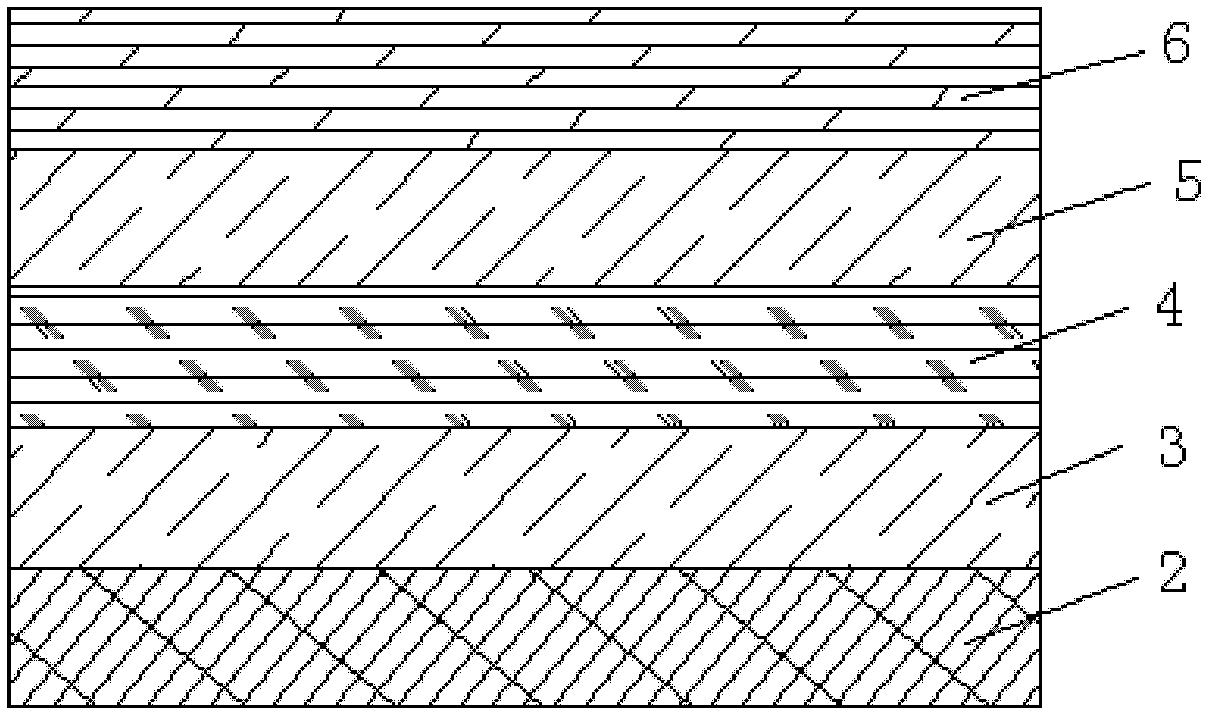

[0051] Using a three-roll calender, the reflective layer 2, the first insulating layer 3, the polymer PTC conductive braiding layer 4, the second insulating layer 5, and the flame-retardant layer 6, which are arranged in sequence from bottom to top, are calendered and composited at a temperature of 130°C. , water-cooled, and rolled to obtain the one-way heat transfer flame-retardant PTC polymer self-limiting temperature electric heating film of the present invention.

[0052] Among them, the reflective layer 2 is a composite magnesium aluminum silicate filled low-density polyethylene melt extruded film, the first insulating layer 3 and the second insulating layer 5 are both low-density polyethylene films, and the flame-retardant layer 6 contains 20 parts by weight A low-density polyethylene film made of hexaisopropoxyphosphazene, 30 parts by weight of hydrated magnesium oxide, 5 parts by weight of pentaerythritol, and 20 parts by weight of melamine composite flame retardant.

...

Embodiment 2

[0058] Using a three-roll calender, the reflective layer 2, the first insulating layer 3, the polymer PTC conductive braiding layer 4, the second insulating layer 5, and the flame-retardant layer 6, which are arranged in sequence from bottom to top, are calendered and composited at a temperature of 180°C. , water-cooled, and rolled to obtain the one-way heat transfer flame-retardant PTC polymer self-limiting temperature electric heating film of the present invention.

[0059] Among them, the reflective layer 2 is aluminum foil, the first insulating layer 3 and the second insulating layer 5 are high-density polyethylene films filled with 40 parts by weight of calcium carbonate, and the flame-retardant layer 6 is a film containing 10 parts by weight of hexaisopropoxyphosphazene , 40 parts by weight of hydrated magnesium oxide, 10 parts by weight of pentaerythritol, and a high-density polyethylene film of 15 parts by weight of melamine composite flame retardant.

[0060] The poly...

Embodiment 3

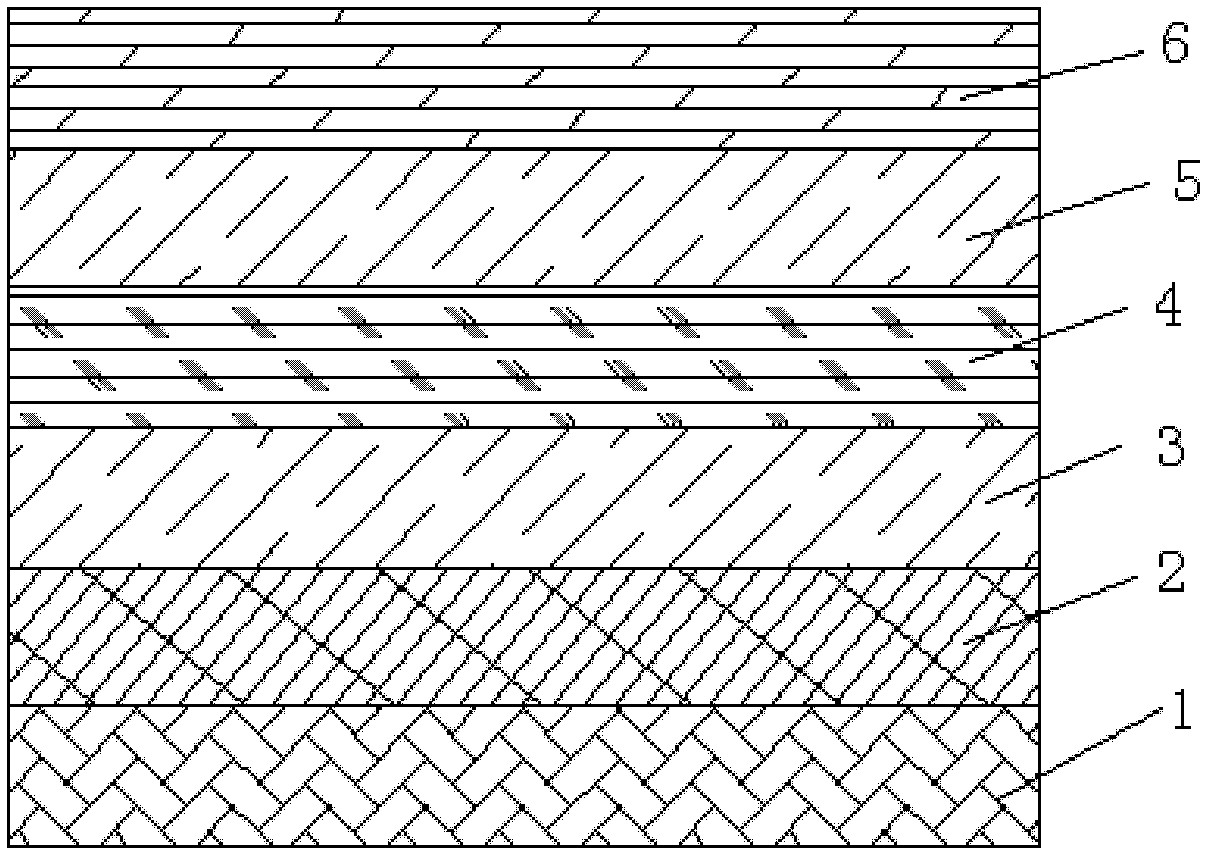

[0065] Using a three-roll calender, the foamed flame-retardant and heat-insulating layer 1, the reflective layer 2, the first insulating layer 3, the polymer PTC conductive braiding layer 4, the second insulating layer 5, and the flame-retardant layer 6 are sequentially arranged from bottom to top. At a temperature of 220°C, calendering and compounding, water cooling, and winding, the unidirectional heat transfer and flame-retardant PTC polymer self-limiting temperature electric heating film of the present invention is obtained.

[0066] Among them, the foaming flame-retardant heat-insulating layer 1 is a low-foaming flame-retardant high-density polyethylene film, the reflective layer 2 is aluminum foil, and the first insulating layer 3 and the second insulating layer 5 are high-density foam filled with 40 parts by weight of calcium carbonate. The polyethylene film, the flame-retardant layer 6 is a high-density polyethylene film containing 10 parts by weight of hexaisopropoxyph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com