High-strength antistatic 3D sheet and preparation method thereof

An anti-static, high-strength technology, applied in the field of sheet processing, can solve problems such as breakdown of mobile phone components, combustion and explosion, and loss of mobile phone life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

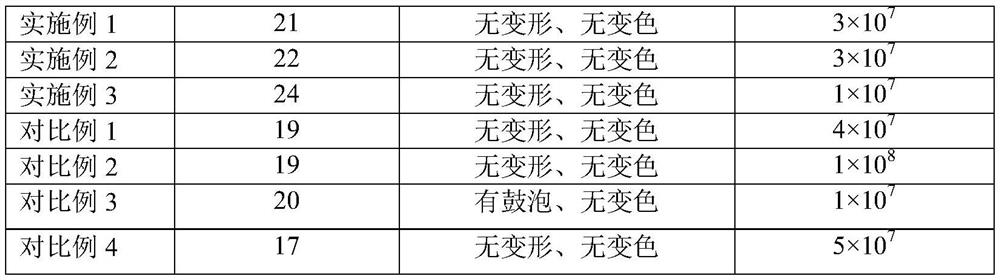

Embodiment 1

[0039] A high-strength antistatic 3D sheet, the preparation method of which comprises the following steps;

[0040] (1) prepare prepreg; S1. get nano diamond powder and toluene solvent to mix, ultrasonic dispersion 7min, obtain nano diamond dispersion; 115°C, react for 4 hours, wash with distilled water three times, dehydrate at a vacuum degree of -0.099MpaMpa, dry to constant weight, and obtain pretreated nano-diamond powder;

[0041] Dissolve the resin in dimethylformamide, cool down to -20°C, add crosslinking agent, antioxidant, and pretreated nano-diamond powder, stir for 8 minutes, then add curing agent, stir for 30 minutes, and the stirring speed is 800r / min, get the glue;

[0042]S2. Arrange the glass fibers in a mixture of PEDOT and sodium polystyrene sulfonate with a mass concentration of 5 mg / mL, soak for 30 minutes, take out the glass fiber cloth, add a phosphoric acid solution with a mass concentration of 30wt.%, and soak for 8 minutes; take out Glass fiber cloth...

Embodiment 2

[0050] A high-strength antistatic 3D sheet, the preparation method of which comprises the following steps;

[0051] (1) prepare prepreg; S1. get nano diamond powder and toluene solvent to mix, ultrasonic dispersion 9min, obtain nano diamond dispersion; 127°C, react for 5 hours, wash with distilled water three times, dehydrate at a vacuum degree of -0.097Mpa, and dry to constant weight to obtain pretreated nano-diamond powder;

[0052] Dissolve the resin in dimethylformamide, cool down to -20°C, add crosslinking agent, antioxidant, and pretreated nano-diamond powder, stir for 9 minutes, then add curing agent, stir for 32 minutes, and the stirring speed is 900r / min. get the glue;

[0053] S2. Arrange the glass fibers in a mixture of PEDOT and sodium polystyrene sulfonate with a mass concentration of 5 mg / mL, soak for 36 minutes, take out the glass fiber cloth, add a phosphoric acid solution with a mass concentration of 30wt.%, and soak for 9 minutes; Glass fiber cloth, wash 3 ...

Embodiment 3

[0061] A high-strength antistatic 3D sheet, the preparation method of which comprises the following steps;

[0062] (1) prepare prepreg; S1. get nano diamond powder and toluene solvent to mix, ultrasonic dispersion 10min, obtain nano diamond dispersion liquid; 135°C, react for 6 hours, wash with distilled water three times, dehydrate at a vacuum degree of -0.095Mpa, and dry to constant weight to obtain pretreated nano-diamond powder;

[0063] Dissolve the resin in dimethylformamide, cool down to -20°C, add crosslinking agent, antioxidant, and pretreated nano-diamond powder, stir for 10 minutes, then add curing agent, stir for 40 minutes, and the stirring speed is 1000r / min. get the glue;

[0064] S2. Arrange the glass fibers in a mixture of PEDOT and sodium polystyrene sulfonate with a mass concentration of 5 mg / mL, soak for 40 minutes, take out the glass fiber cloth, add a phosphoric acid solution with a mass concentration of 30wt.%, and soak for 10 minutes; take out Glass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com