Graphene nylon composite material and preparation method thereof

A nylon composite material and graphene technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of low thermal conductivity and reduce other properties of polymer materials, and achieve high compatibility and interface adhesion Strong, good heat conduction channel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

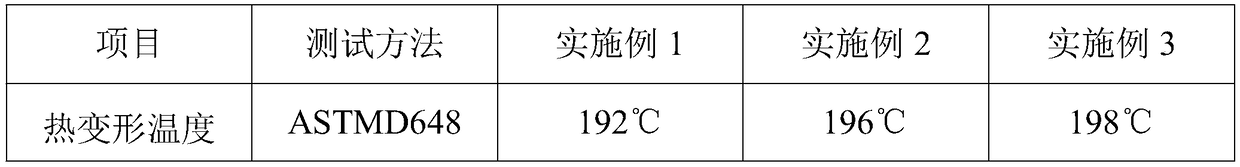

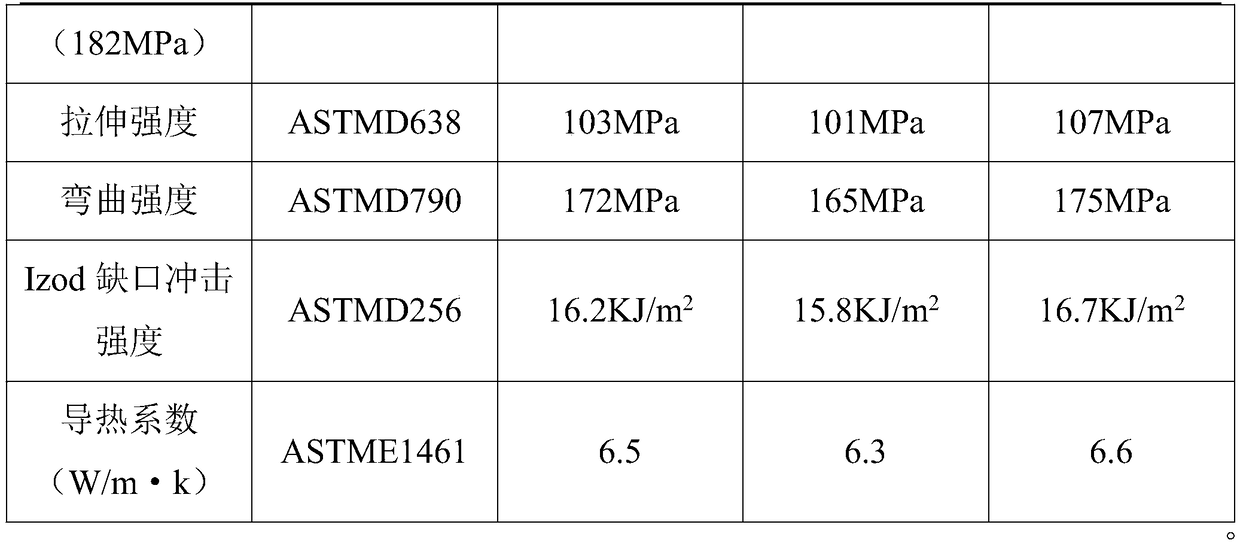

Examples

Embodiment 1

[0028] The preparation method of modified graphene comprises the following steps:

[0029] 1) graphene is added in the ethanol solution of citric acid and carries out ultrasonic dispersion, obtains the alcohol dispersion liquid of carboxylated graphene;

[0030] 2) Add sodium metaaluminate to the alcohol dispersion of carboxylated graphene, then carry out stirring reaction, centrifuge after the reaction finishes, obtain filtrate;

[0031] 3) Heat the filtrate to 400°C at a heating rate of 1°C / min under a nitrogen atmosphere, and keep it warm for 3 hours. The mass ratio of graphene to citric acid is 1:6, and the mass ratio of graphene to sodium metaaluminate is 1:3.

Embodiment 2

[0033] The preparation method of modified graphene comprises the following steps:

[0034] 1) graphene is added in the propanol solution of citric acid and carries out ultrasonic dispersion, obtains the alcohol dispersion liquid of carboxylated graphene;

[0035] 2) Add sodium metaaluminate to the alcohol dispersion of carboxylated graphene, then carry out stirring reaction, centrifuge after the reaction finishes, obtain filtrate;

[0036] 3) Heat the filtrate to 600°C at a heating rate of 5°C / min under nitrogen atmosphere, and keep it warm for 1h. The mass ratio of graphene to citric acid is 1:2, and the mass ratio of graphene to sodium metaaluminate is 1:7.

Embodiment 3

[0038] A graphene nylon composite material, calculated in parts by weight, comprises the following raw materials:

[0039] 80 parts of nylon, 7 parts of carbon fiber, 24 parts of modified graphene of embodiment 1, 6 parts of maleic anhydride grafted ethylene-octene copolymers, 1.2 parts of styrene-maleic anhydride copolymers, 0.4 parts of polyethylene wax and 0.4 part of hindered phenolic antioxidant.

[0040] The preparation method of graphene nylon composite material:

[0041] 1) Nylon, maleic anhydride grafted ethylene-octene copolymer, carbon fiber and the modified graphene of Example 1 were mixed and stirred uniformly, then added to a twin-screw extruder, and extruded at 260°C pellets to obtain thermally conductive nylon masterbatches;

[0042] 2) drying the heat-conducting nylon masterbatch in step 1), and then mixing and stirring evenly with styrene-maleic anhydride copolymer, hindered phenolic antioxidant and polyethylene wax to obtain a mixed material;

[0043] 3) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com