Copper toxicity-resistant glass fiber reinforced polypropylene composite material and preparation method thereof

A technology of composite materials and polypropylene, applied in the field of engineering plastics, to achieve the effects of strong adhesion, reduced activity, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

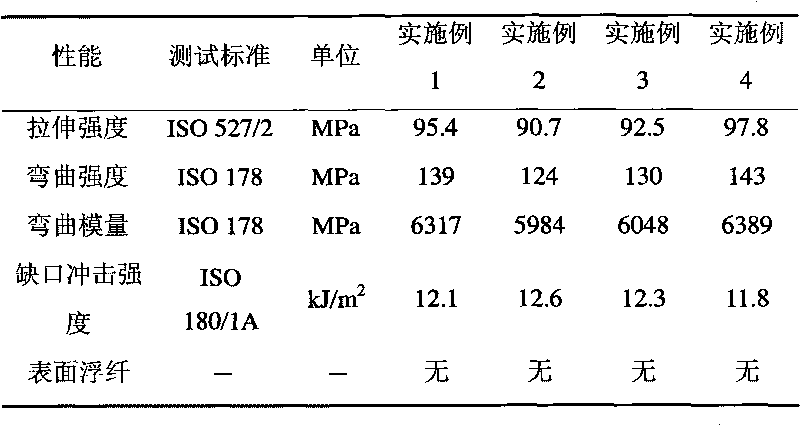

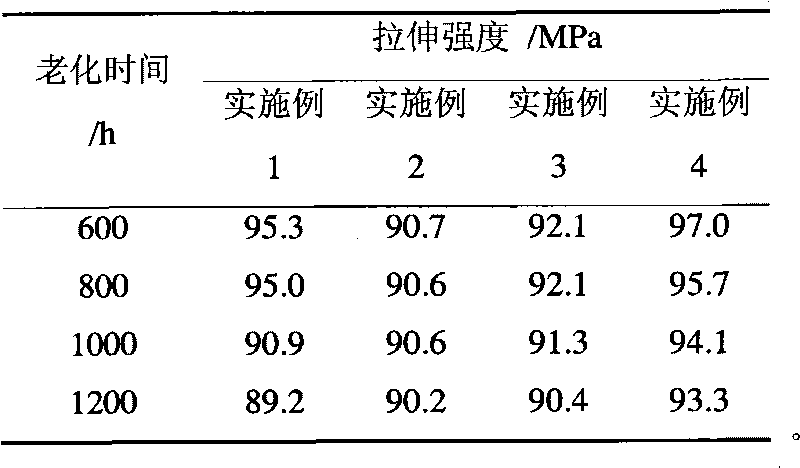

Examples

Embodiment 1

[0023] A glass fiber reinforced polypropylene composite material resistant to copper damage, which is composed of the following raw materials in percentage: high crystalline polypropylene 65%; compatibilizer 2.1%; composite antioxidant 0.8%; processing aid 0.1%; glass fiber 32%.

[0024] The compatibilizer is glycidyl methacrylate grafted polypropylene. Described composite antioxidant is A+B type, and wherein, A is 0.4% four ( -(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid)pentaerythritol ester; B consists of 0.2% bis(2,4-di-tert-butylphenyl)pentaerythritol diphosphite and 0.2% antioxidant Dosage 300 Composition. Described processing aid is ethylene bis stearic acid amide. The glass fibers are short glass fibers of 3-5 cm.

[0025] The preparation method of the above-mentioned copper damage-resistant glass fiber reinforced polypropylene composite material, the specific steps are: firstly mix polypropylene, compatibilizer, composite antioxidant and processing aid in a ...

Embodiment 2

[0028] A glass fiber reinforced polypropylene composite material resistant to copper damage, which is composed of the following raw materials in percentage: high crystalline polypropylene 60%; compatibilizer 7%; composite antioxidant 2%; copper damage resistance 0.2%; processing Additive 0.8%; glass fiber 30%.

[0029] The compatibilizer is maleic anhydride grafted polypropylene. Described composite antioxidant is A+B type, and wherein, A is 1% four ( -(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid)pentaerythritol ester; B consists of 0.5% bis(2,4-di-tert-butylphenyl)pentaerythritol diphosphite and 0.5% antioxidant Agent 1035 composition. The anti-copper poisoning agent is a high-efficiency metal deactivator with a hydrazide structure. The processing aid is an anti-fiber exposure agent. The glass fibers are short glass fibers of 3-5 cm.

[0030] The preparation method of the above-mentioned copper damage-resistant glass fiber reinforced polypropylene composite materia...

Embodiment 3

[0033] A glass fiber reinforced polypropylene composite material resistant to copper damage, which is composed of the following raw materials in percentage: high crystalline polypropylene 62.5%; compatibilizer 3.5%; composite antioxidant 1.4%; copper damage resistance agent 0.1%; processing Additive 0.5%; glass fiber 32%.

[0034] The compatibilizer is maleic anhydride grafted styrene-ethylene-butylene-styrene block copolymer. Described composite antioxidant is A+B type, and wherein, A is 0.7% four ( -(3,5-di-tert-butyl-4-hydroxyphenyl)propionate) pentaerythritol; B is 0.7% bis(2,4-di-tert-butylphenyl)pentaerythritol diphosphite. The anti-copper poisoning agent is an efficient metal deactivator with a hydrazide structure. The processing aids are 0.2% ethylene bis stearic acid amide and 0.3% anti-fiber exposure agent. The glass fibers are short glass fibers of 3-5 cm.

[0035] The preparation method of the above-mentioned copper damage-resistant glass fiber reinforced poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com