Corrosion-resistant flexible epoxy resin root puncture-resistant waterproof composite material

A flexible epoxy resin and root puncture-resistant technology, which is applied to roofs, roof coverings, buildings, etc. using flexible materials, can solve the problems of difficult handling of inner corners, large pollution, poor mechanical properties and ductility, etc. Root puncture resistance and waterproof effect, avoid energy consumption and large pollution, and improve the effect of waterproof safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

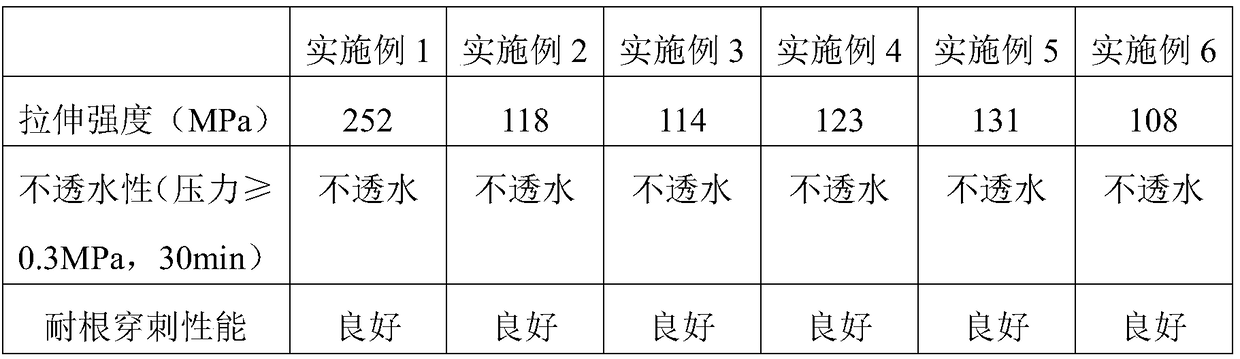

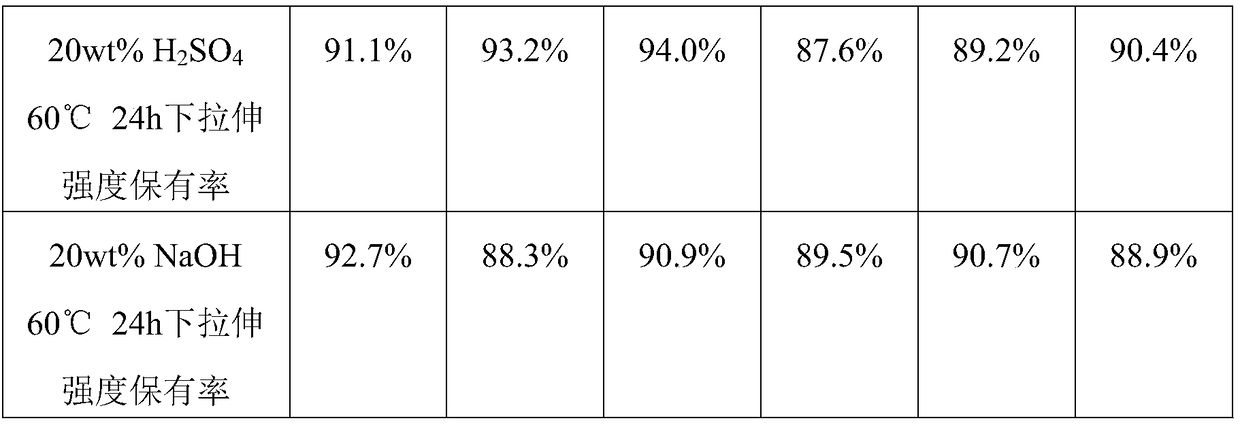

Examples

Embodiment 1

[0031] 1) Arranging the glass fibers in a degreasing liquid for 30 minutes at 40° C., and placing the treated glass fibers in 10 wt % dilute sulfuric acid to neutralize the lye on the surface;

[0032] The formula of the degreasing liquid is: a mixed solution of sodium hydroxide 60g / L, sodium carbonate 30g / L and sodium phosphate 15g / L;

[0033] 2) Arrange the degreased and neutralized glass fiber in step 1) in the sensitization solution, sensitize it at 25°C for 10 minutes, and rinse it repeatedly with clean water;

[0034] The sensitizing solution is: a mixed solution of 10 g / L of stannous chloride and 40 ml / L of hydrochloric acid; the percentage concentration of hydrochloric acid is 38%.

[0035] 3) Arrange the glass fiber sensitized in step 2) in the activation solution and activate it at 25°C for 10 minutes, and the Pd in the solution 2+ The ions are converted into metal Pd particles, and then placed in 10g / L sodium hypophosphite for 10min to reduce the Pd on the surfac...

Embodiment 2

[0042] Embodiment 2, with embodiment 1, the difference is,

[0043] 1) Place the glass fiber bundles in a degreasing solution for 30 minutes at 40°C, and place the treated glass fiber bundles in 10 wt% dilute sulfuric acid to neutralize the lye on the surface;

[0044] 4) Use ammonia water to adjust the pH value of the plating solution to 10, place the activated glass fiber bundles in step 3) in the copper plating solution, perform copper plating at 80° C. for 20 minutes, and dry to obtain copper-plated glass fiber bundles;

[0045] Described copper plating liquid is: copper sulfate 40g / L, sodium hypophosphite 30g / L, sodium citrate 60g / L, the mixed solution of ammonium chloride 50g / L and thiourea 5mg / L;

[0046] 5) The mass parts are 100 parts of bisphenol A type E51 epoxy resin, 55 parts of curing agent D400 polyetheramine, 10 parts of plasticizer dibutyl phthalate, 4 parts of curing accelerator nonylphenol, furfural 30 parts of phenolic resins are uniformly stirred by machi...

Embodiment 3

[0057] Embodiment 3, with embodiment 1, the difference is,

[0058] 1) Place the glass fiber bundles in a degreasing solution for 30 minutes at 40°C, and place the treated glass fiber bundles in 10 wt% dilute sulfuric acid to neutralize the lye on the surface;

[0059] 4) Adjust the pH value of the plating solution to 11 with ammonia water, place the activated glass fiber bundles in step 3) in the copper plating solution, and perform copper plating at 90° C. for 30 minutes to obtain copper-plated glass fiber bundles;

[0060] Described copper plating liquid is: copper sulfate 50g / L, sodium hypophosphite 40g / L, sodium citrate 70g / L, the mixed solution of ammonium chloride 60g / L and thiourea 6mg / L;

[0061] 5) The mass parts are 100 parts of bisphenol A type E51 epoxy resin, 55 parts of curing agent D400 polyetheramine, 10 parts of plasticizer dibutyl phthalate, 4 parts of curing accelerator nonylphenol, furfural 35 parts of phenolic resins are uniformly stirred by machinery to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com