Super absorbent polymer

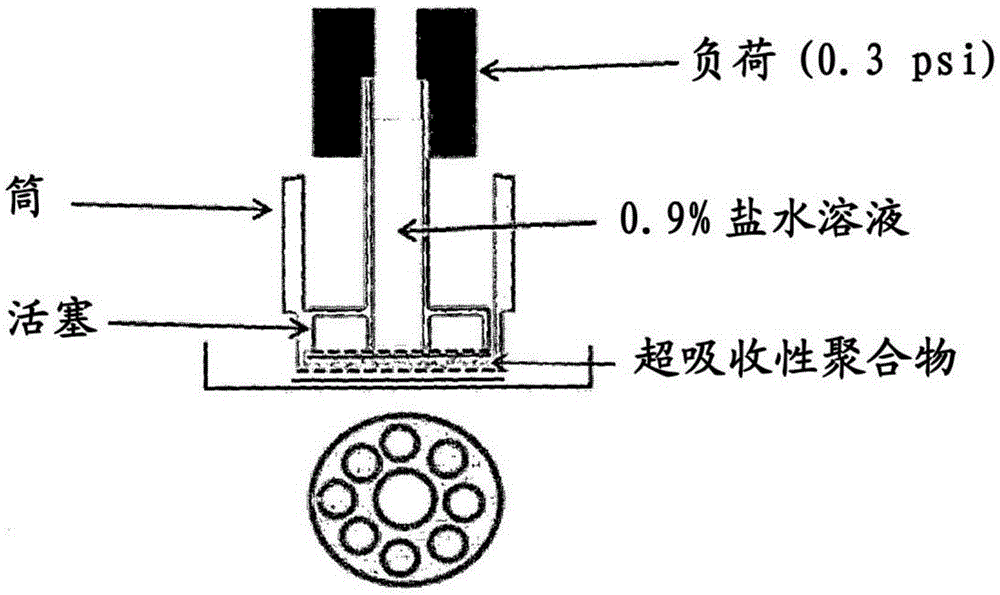

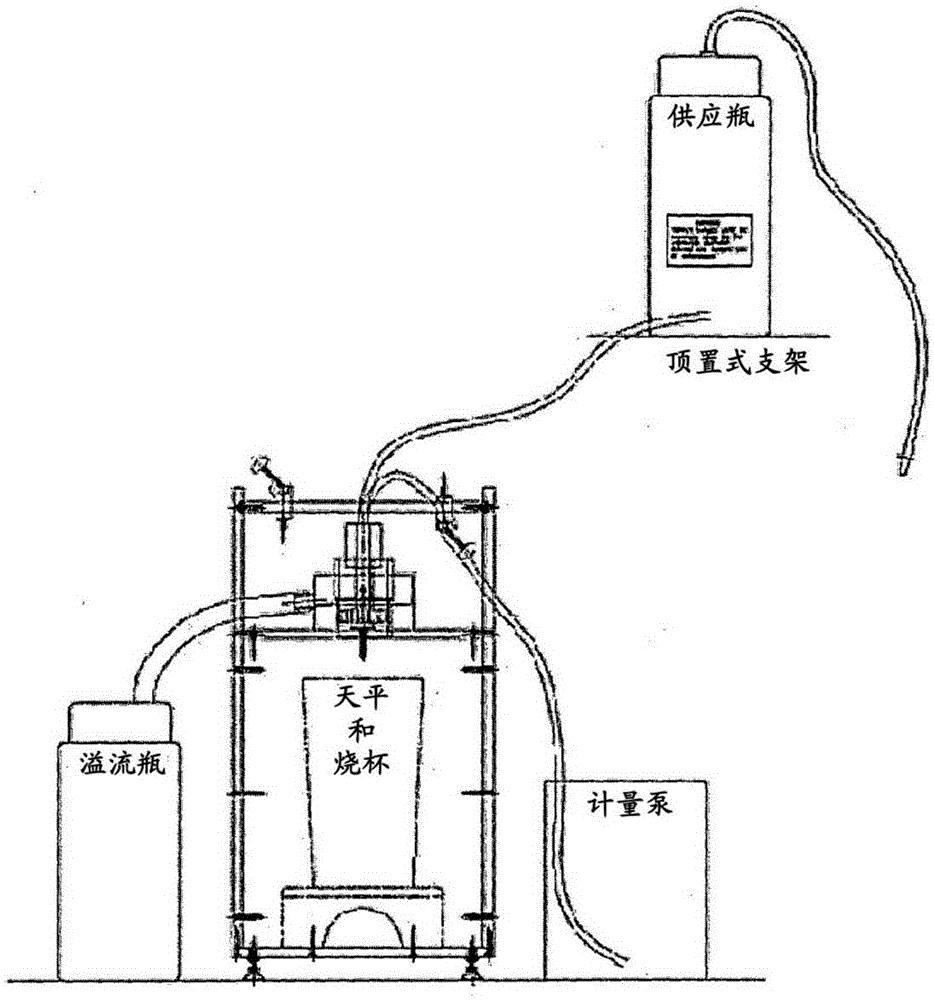

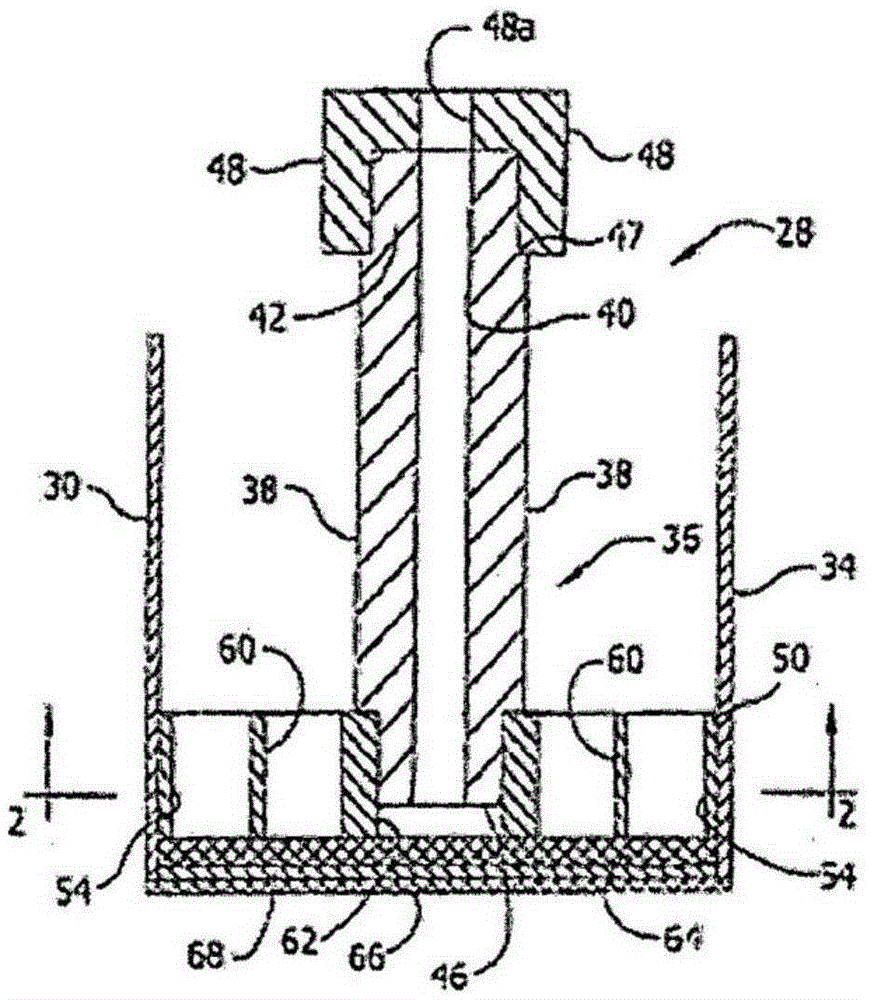

一种超吸收性、聚合物的技术,应用在吸收垫、医药科学、绷带等方向,能够解决超吸收性聚合物分离、吸收度减小等问题,达到优异吸收性、舒适穿戴感、优异初始吸收性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0135] In a 2L glass reactor surrounded by a jacket (through which a heating medium pre-cooled at 25° C. was circulated), 500 g of acrylic acid was mixed with 11 g of 0.5% IRGACURE 819 initiator diluted in acrylic acid (110 ppm, based on monomer Composition) mixing, inject 5% polyethylene glycol diacrylate (PEGDA, molecular weight 400, curing dose 200mJ / cm2) through acrylic acid dilution of 26g 2 ) solution (A solution), and inject 14g of trimethylolpropane triacrylate (ethoxylated TMPTA, TMP (EO) 9TA, M-3190MiwonSpecialtyChemicalCo. , Ltd., curing dose 200mJ / cm 2 ) solution (B solution), and then slowly add 800 g of 24% caustic soda solution (C solution) dropwise. The degree of neutralization of acrylic acid in sodium acrylate obtained as a water-soluble ethylenically unsaturated monomer was 70 mol%.

[0136] When it was determined that the temperature of the mixture was raised to 80°C or higher by the heat of neutralization when mixing the two solutions, the mixture was al...

Embodiment 2

[0143] A superabsorbent polymer was prepared in the same manner as in Example 1, except that 0.2 g of diatomaceous earth was used instead of the Aerosil 200 treated in the drying process in Example 1.

Embodiment 3

[0145] A superabsorbent polymer was prepared in the same manner as in Example 1, except that, for the surface treatment of the base polymer obtained in Example 1, 100 g of the base polymer was mixed with 3 g of water, 1.0 g of ethylene carbonate Esters and 0.1 g of Aerosil200 prepared cross-linking agent solution were mixed, the surface cross-linking reaction was carried out at 190°C for 30 minutes, and then the resultant was pulverized and sieved to obtain surface-treated superabsorbent polymer with a particle size of 150 μm to 850 μm things.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

| permeability | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com