Method for ecologically improving tobacco-planting soil

A soil and ecological technology, applied in the field of ecological improvement of tobacco planting soil, can solve the problems of unfavorable sustainable development of tobacco, reduction of soil organic matter content, deterioration of soil physical and chemical properties, etc., and achieve the effects of saving manpower, reducing biomass and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

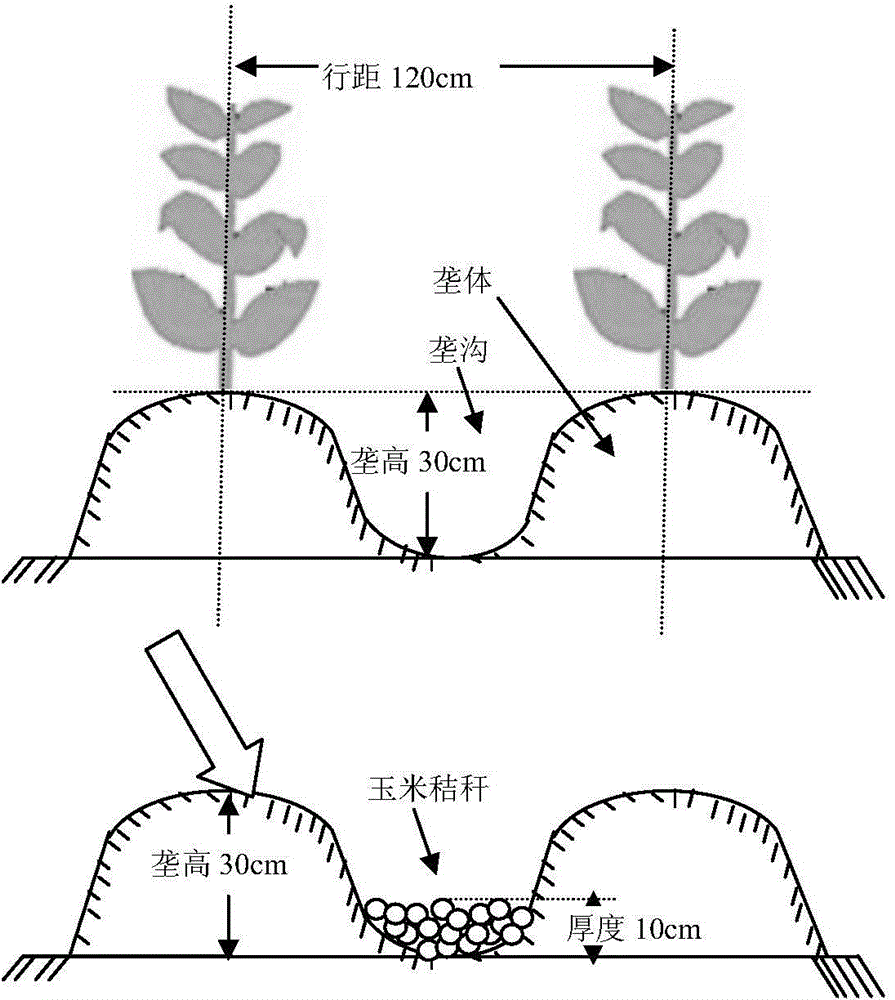

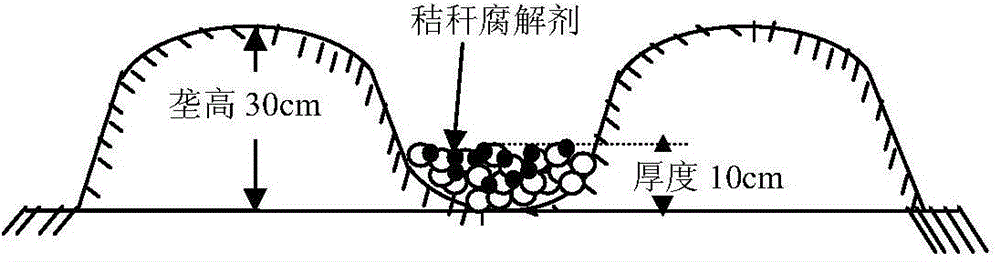

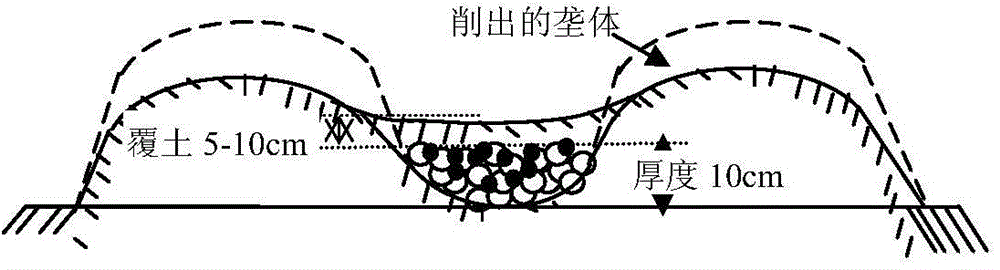

[0033] In a flue-cured tobacco cultivation site in a mountainous area, an application experiment of soil ecological improvement methods for tobacco planting was carried out. The flue-cured tobacco is harvested in September of the first year, and the tobacco stems are pulled out in early October. In mid-October, cut the corn stalks into small pieces of 50-100cm, spread them in the original furrows, and use 500kg / mu. Use 2 kg / mu of organic waste fermented koji produced by Beijing Jingpuyuan Bioengineering Co., Ltd. to spread evenly on the corn stalks, and then cover with soil. The soil covering method is to cut the original ridge from the middle, make the soil on the ridge fall to the direction of the furrow, bury the corn stalks, and cover the soil with a thickness of about 7cm. After covering with soil, make the furrow slightly conca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com