Method for high-yield cultivation of hybrid millet of coastal moderate and severe saline and alkaline land

A technology of severe saline-alkali land and cultivation method, applied in the field of high-yield cultivation, can solve the problems of less hybrid millet, high-yield cultivation technology needs to be studied, etc., and achieves the effect of reducing the amount of seeds used, helping the emergence and growth, and reducing labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

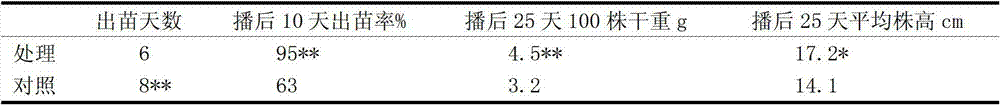

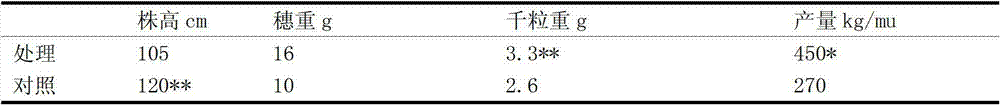

Examples

Embodiment 1

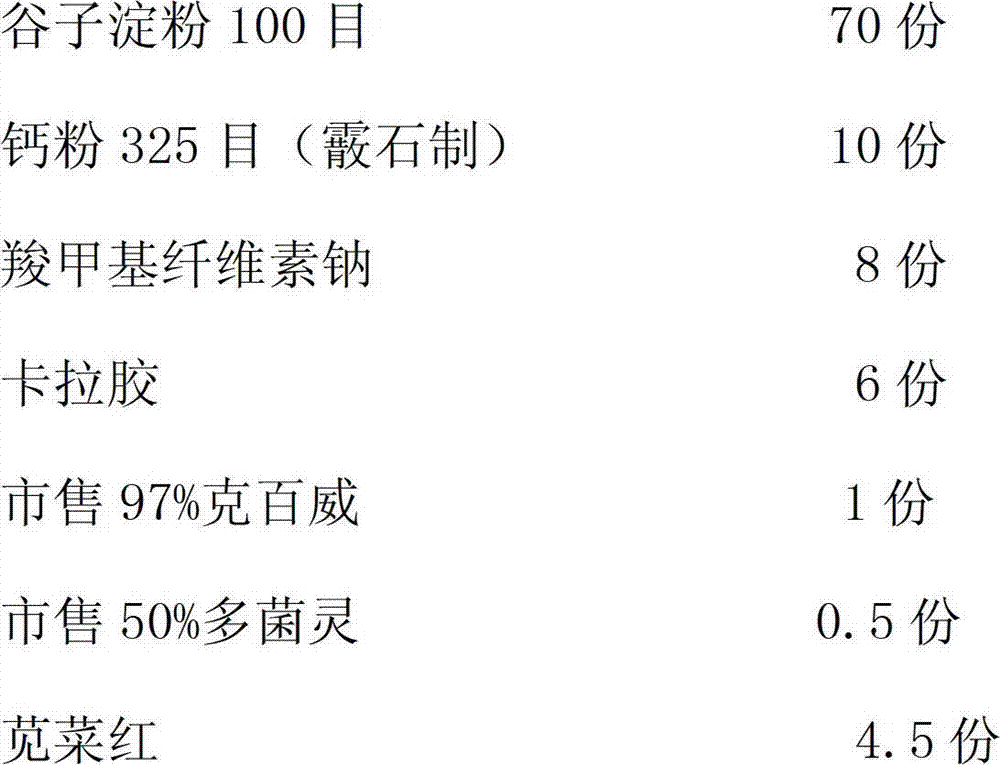

[0032] 1. Pelletization of hybrid millet, weight components and content of pelletization coating agent:

[0033]

[0034] Two, prepare the hybridized millet pellet seed according to the following method:

[0035] ①Put 70 parts of 100-mesh millet starch, 10 parts of 325-mesh calcium powder, 1 part of 97% carbofuran, 0.5 parts of 50% carbendazim powder and 4.5 parts of amaranth pigment into a blender and mix thoroughly to make hybrid millet pills Granulated powder;

[0036] ②Dissolve 8 parts of sodium carboxymethylcellulose in water to prepare an adhesive;

[0037] ③Put the seeds of hybrid millet (the Zhangzagu series selected by Zhao Zhihai of Zhangjiakou Academy of Agricultural Sciences, especially Zhangzagu No. 8) into the pelletizing machine, and spray the adhesive in step ⑤ on the seeds, Spray the product in step ① into it again to form a certain thickness of coating in the pelletizing machine;

[0038] ④ Make carrageenan into slurry, and spray gelatin onto the surfac...

Embodiment 2

[0057] 1. Pelletization of hybrid millet, weight components and content of pelletization coating agent:

[0058]

[0059] Two, prepare the hybridized millet pellet seed according to the following method:

[0060] ①Put 75 parts of 80-mesh millet starch, 10 parts of 300-mesh calcium powder, 1 part of 97% carbofuran, 0.7 parts of 50% carbendazim powder and 4.3 parts of amaranth pigment into a mixer and mix thoroughly to make hybrid millet pills Granulated powder;

[0061] ② Dissolving 5 parts of sodium carboxymethylcellulose in water to prepare an adhesive;

[0062] ③ Put the seeds of hybrid millet (Zhang Zagu No. 8) into the pelletizing machine, spray the adhesive in step ② on the seeds; then spray the product of step ① into it, and form a certain thickness in the pelletizing machine coating;

[0063] ④ Make carrageenan into slurry, and spray gelatin onto the surface of pellet seeds when the temperature is lower than 75°C to form a layer of colloidal coating film;

[0064...

Embodiment 3

[0082] 1. Pelletization of hybrid millet, composition and content of pelletization coating agent:

[0083]

[0084]

[0085] Two, prepare the hybridized millet pellet seed according to the following method:

[0086] ①Put 65 parts of 105 mesh millet starch, 15 parts of 400 mesh calcium powder, 1 part of 97% carbofuran, 0.6 parts of 50% carbendazim powder and 5.4 parts of amaranth pigment into a blender and mix thoroughly to make hybrid millet pills Granulated powder;

[0087] ② Dissolving 6 parts of sodium carboxymethylcellulose in water to prepare an adhesive;

[0088] ③ Put the seeds of hybrid millet (Zhang Zagu No. 8) into the pelletizing machine, spray the adhesive of step ② on the seeds; then spray the product of step ① into it, and form a certain thickness in the pelletizing machine coating;

[0089] ④ Make carrageenan into slurry, and spray gelatin onto the surface of pellet seeds when the temperature is lower than 75°C to form a layer of colloidal coating film;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com