Rotary shaft type solid state fermentation tank

A solid-state fermenter and fermenter technology, applied in the direction of solid-phase fermentation bioreactor, bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, etc., can solve the problem of solid-state fermenter heat dissipation, mass transfer problems such as difficult bacteria, to achieve the effect of improving heat exchange efficiency, uniform moisture, and high precision of humidity control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

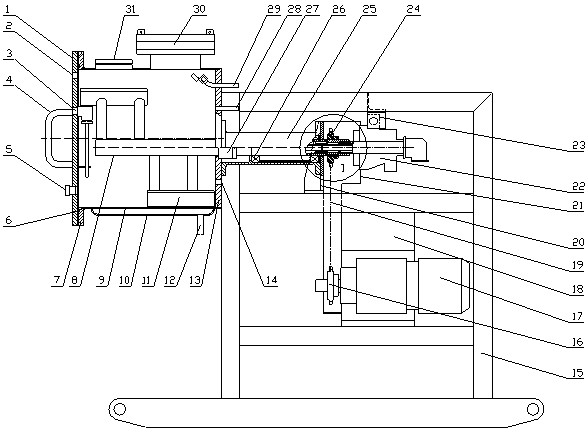

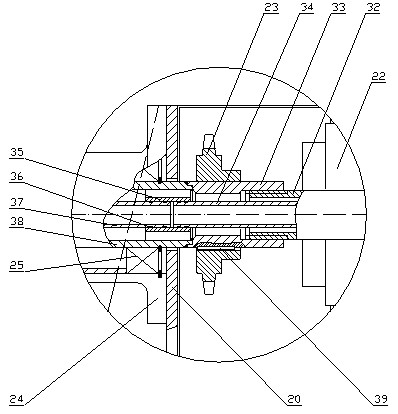

[0022] The present invention will be further described below in conjunction with specific drawings.

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 with Figure 7 As shown, the shaft-type solid-state fermentation tank includes a fermentation tank body, a support 15, a rotating stirring mass transfer heat transfer device and a driving device.

[0024] The fermentation tank body is a horizontal cylindrical tank body, including an inner cylinder 9, one end of the inner cylinder 9 is welded to the bottom 13, and the other end is welded to the flange 7, and the flange 7 and the end cover 1 are assembled on the Together, the flange 7 and the end cover 1 are sealed with a sealing ring 6, and a jacket 10 is distributed on the outer periphery of the inner cylinder 9, because the solid material will not touch the top of the inner cylinder 9, so the jacket 10 preferably only covers the inner cylinder 9 in the lower middle. The bottom of the cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com