Positive-negative pressure ventilation drying cylindrical silo and drying method

A ventilation and drying, positive and negative pressure technology, applied in the direction of drying gas arrangement, botany equipment and methods, drying, etc., can solve the problems of high drying energy consumption, large mechanical damage of rice, increased fracture rate, etc., to reduce the moisture gradient problems, reducing the number of uses, and avoiding the effects of short circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

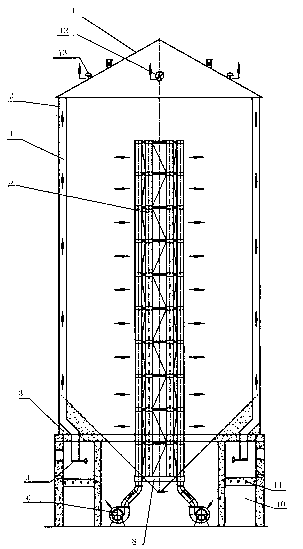

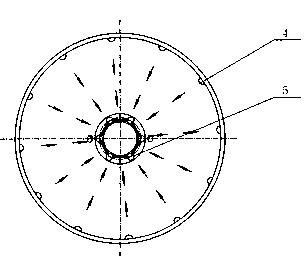

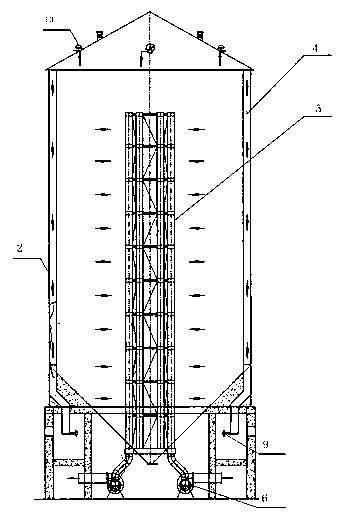

[0031] A positive and negative pressure ventilated drying silo, which consists of: a silo roof 1, a silo body 2 connected to the silo roof, a foundation 3 connected to the silo body, and fixed on the inner wall of the silo The ventilation cage 4 of the outer ring, the ventilation cage of the outer ring is evenly distributed in the ring, the ventilation cage 5 of the center is housed in the described silo, and the ventilation cage of the outer ring includes the ventilation cage of the outer ring and the ventilation cage of the center The ventilation cages are all connected to the blower fan 6.

Embodiment 2

[0033] Example 1 In the positive and negative pressure ventilation drying silo, the cross-section of each ventilation pipe of the ventilation cage of the outer ring is a semicircle, and the flat side of the semicircle is attached to the inner wall of the silo, That is, it is located on the side of the inner wall of the warehouse, and will not trap grain.

Embodiment 3

[0035] Example 1 or 2 In the positive and negative pressure ventilation drying silo, the ventilation cage in the center includes a group of ventilation pipes 7, the number of the ventilation pipes is 1-30, and the ventilation pipes are arranged in a ring shape, and the ventilation pipes Converging at the bottom of the silo, the number of rings in the circular distribution of the ventilation pipes is 1-4 rings, and the thickness of the grain layer can be only one central ventilation pipe to ensure that the thickness of the grain layer is not more than 4 meters. The ventilation pipes of the adjacent rings have different wind directions, and the adjacent rings of the air inlet ventilation pipes are the air outlet ventilation pipes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com