Seed sprouting hydroponic device

A hydroponic device and seed technology, applied in cultivation, germination equipment, soilless cultivation and other directions, can solve problems such as increased production cost, high cultivation cost, cultivation environment control, etc., achieve convenient control and operation, improve area yield, The effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

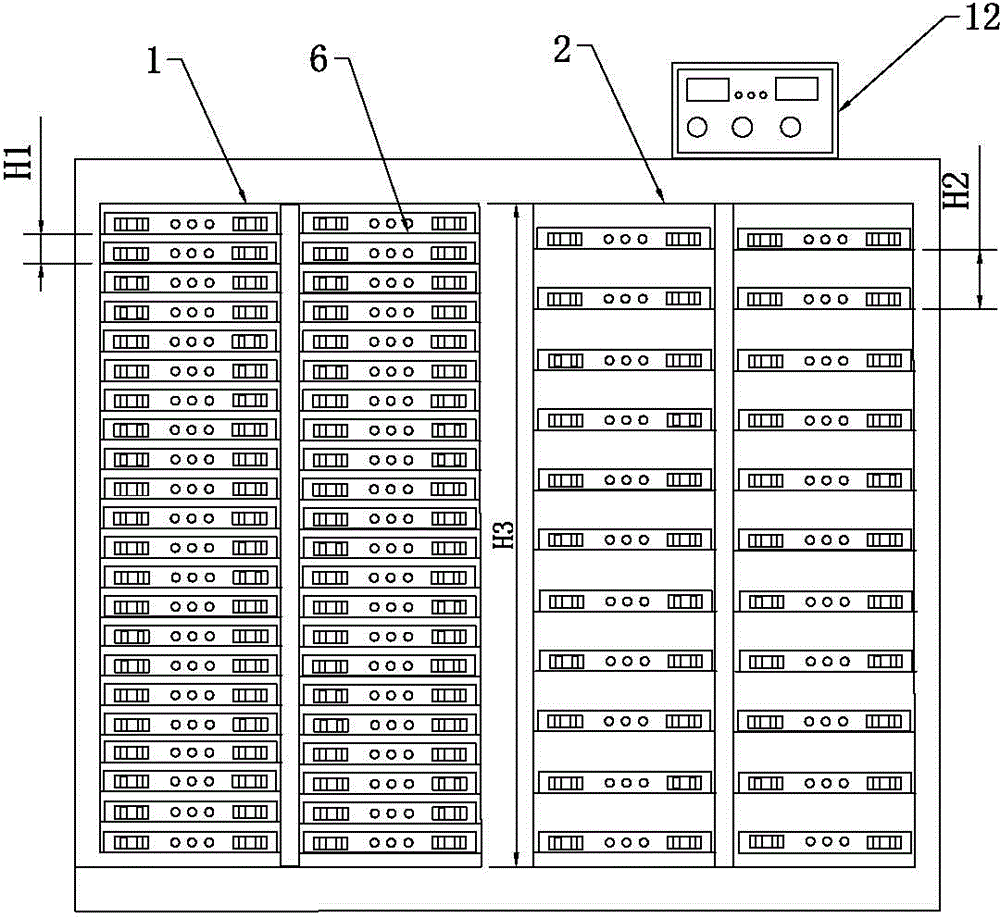

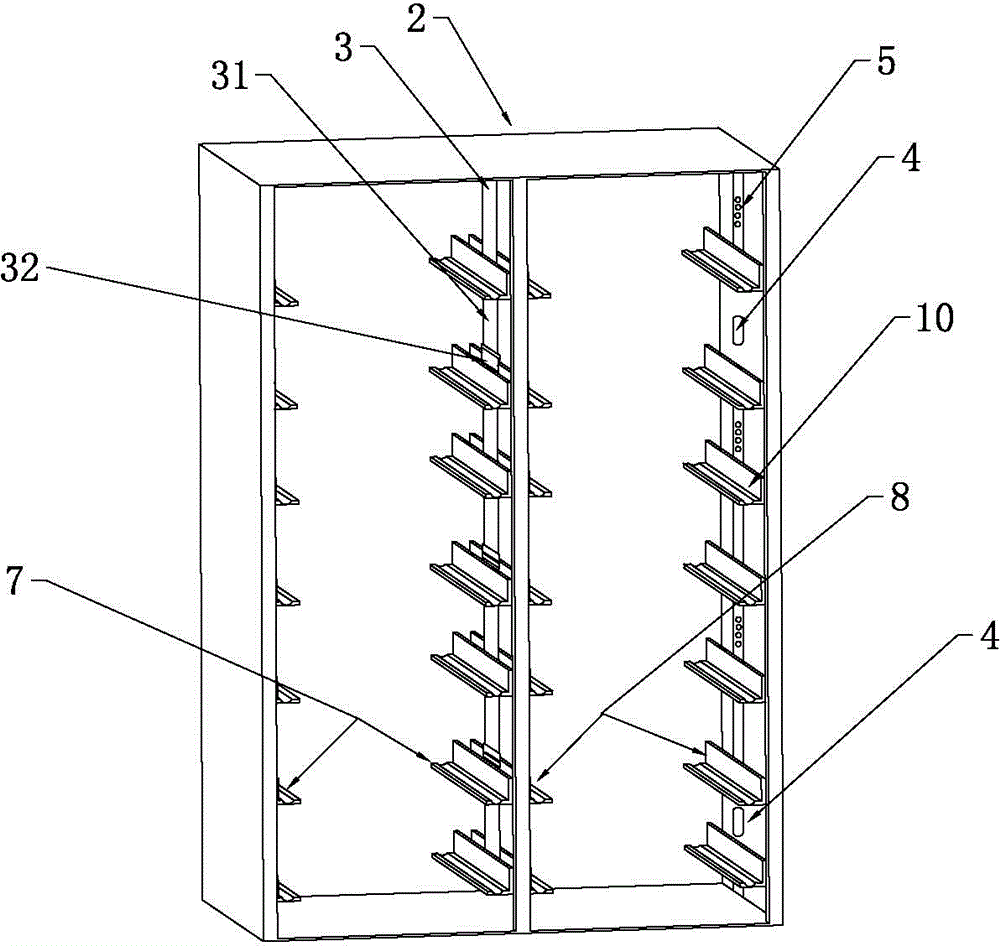

[0040] Such as Figures 1 to 2 As shown, a kind of hydroponic device for seed germination comprises a main box body and a central control system 12 electrically connected to the main box body. The wall of the main box body is provided with an insulating material layer, and the main box body is provided with a germination chamber 1 And nursery room 2, the middle part longitudinal direction in the germination room 1 is provided with the central spraying device 3, is provided with the ultraviolet germicidal lamp in the germination room 1, is provided with the central spraying device 3 in the middle part longitudinal direction in the seedling room 2, and the seedling room 2 An ultraviolet germicidal lamp 4 and a plant lamp 5 are arranged inside.

[0041] The central spraying device 3 includes a water delivery pipe 31 longitudinally arranged between the left frame 7 and the right frame 8 and a 360° spray nozzle 32 connected to the water delivery pipe 31, and the water delivery pipe...

Embodiment 2

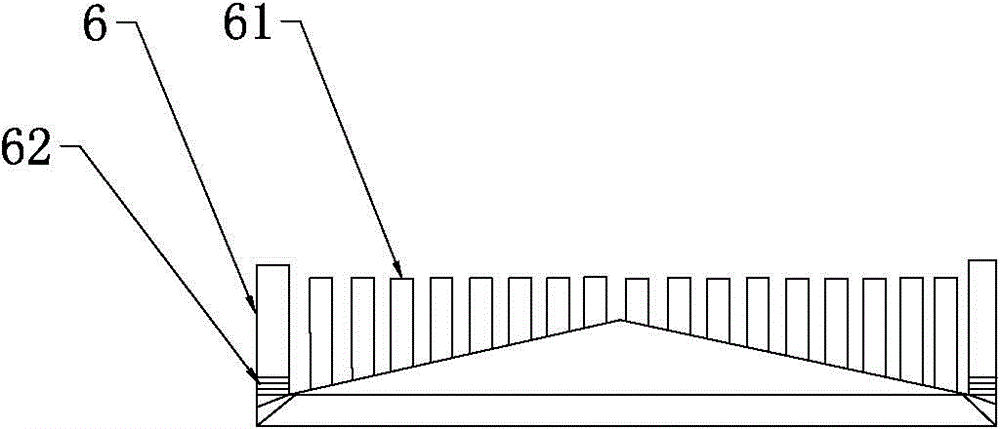

[0054] The difference between this embodiment and Embodiment 1 is that further, the central spraying device 3 includes a water delivery pipe 31 longitudinally arranged between the left frame 7 and the right frame 8 and a 360° spray nozzle 32 connected to the water delivery pipe 31 , the water pipe 31 is provided with several 360 ° spray nozzles 32. Specifically, the two ends of the 360° spray nozzle 32 are provided with threads connected to the water pipe 31, the middle circumference of the 360° spray nozzle 32 is provided with several water outlets, and the middle part of the 360° spray nozzle 32 is provided with a relatively rotatable Pressure head, by controlling the gap between the two pressure heads to control the atomization degree of the water sprayed by the nozzle, the water delivery pipe 31 is arranged between the two rows of seedling trays 6 before and after, that is, the middle part of the four seedling trays 6 , A 360° spray nozzle 32 is arranged between the seedli...

Embodiment 3

[0061] In this embodiment, the hydroponic device is further limited, at least two rows of seedling trays 6 can be placed in the longitudinal direction of the germination accelerating room 1 and the seedling raising room 2 . Increase the utilization rate of the germination chamber 1 and the nursery chamber 2, and increase the area yield.

[0062] Such as Figure 5 As shown, further, the number of the germination chambers 1 is at least two, and the two germination chambers 1 are connected, and the doors 9 of the two germination chambers 1 are respectively located on both sides of the main box and are misplaced; The quantity of the seedling-raising chambers 2 is at least four, and the four seedling-raising chambers 2 are connected, and the doors 9 of the four seedling-raising chambers 2 are staggeredly arranged on both sides of the main casing. That is, only two rows of four rows of seedling trays 6 are placed in each germination room 1 or seedling room 2, a single germination r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com