Hot-pressing production process of standard paperboard

A production process and cardboard technology, applied in the direction of papermaking, paper machine, fiberboard, etc., can solve the problems of uneven paper surface warping, unstable cardboard thickness, high labor intensity of workers, etc., achieve uniform moisture content, improve processing precision, The effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and 2

[0009] Examples 1 and 2, the data without brackets are from Example 1, and the data in brackets are from Example 2.

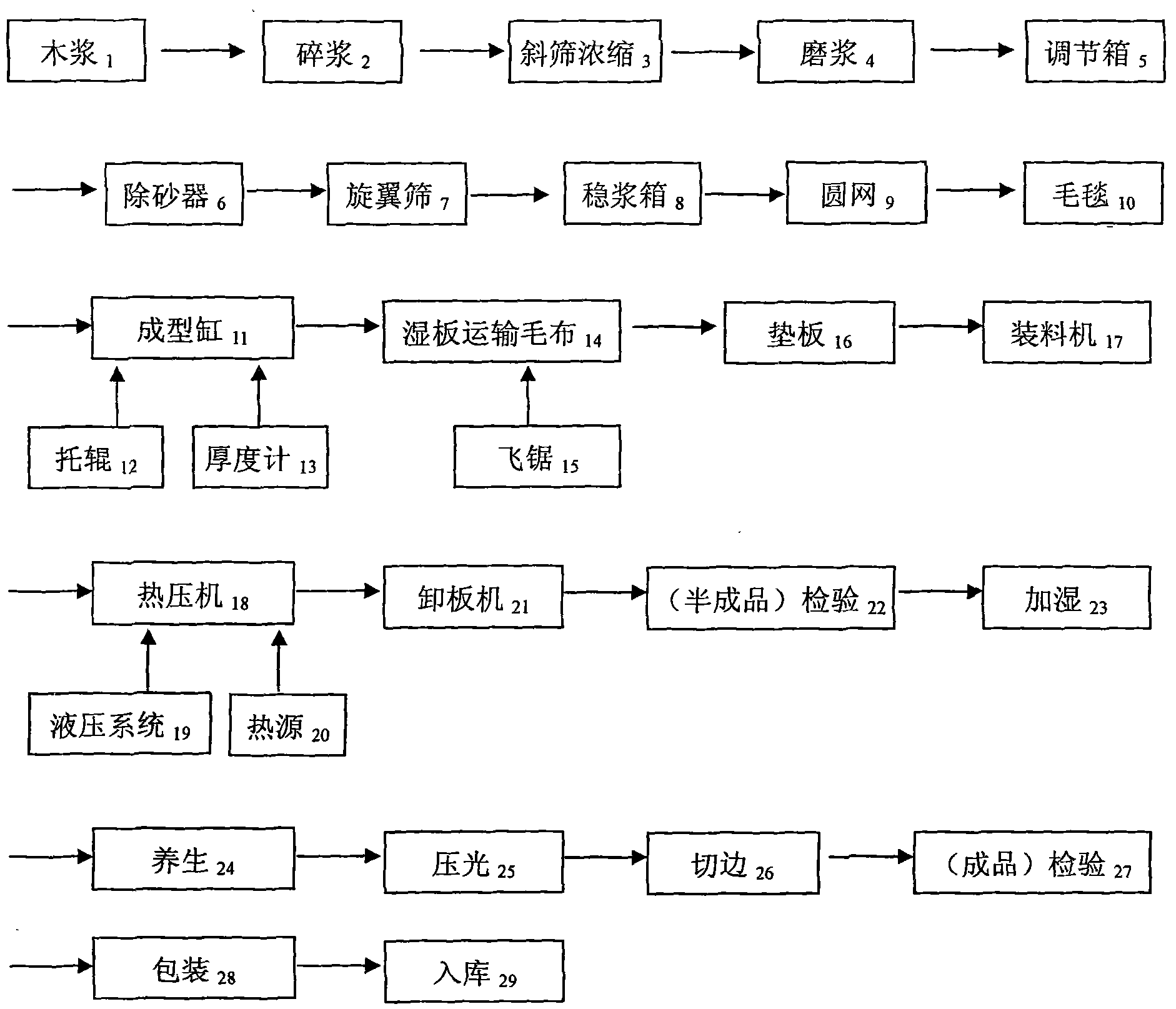

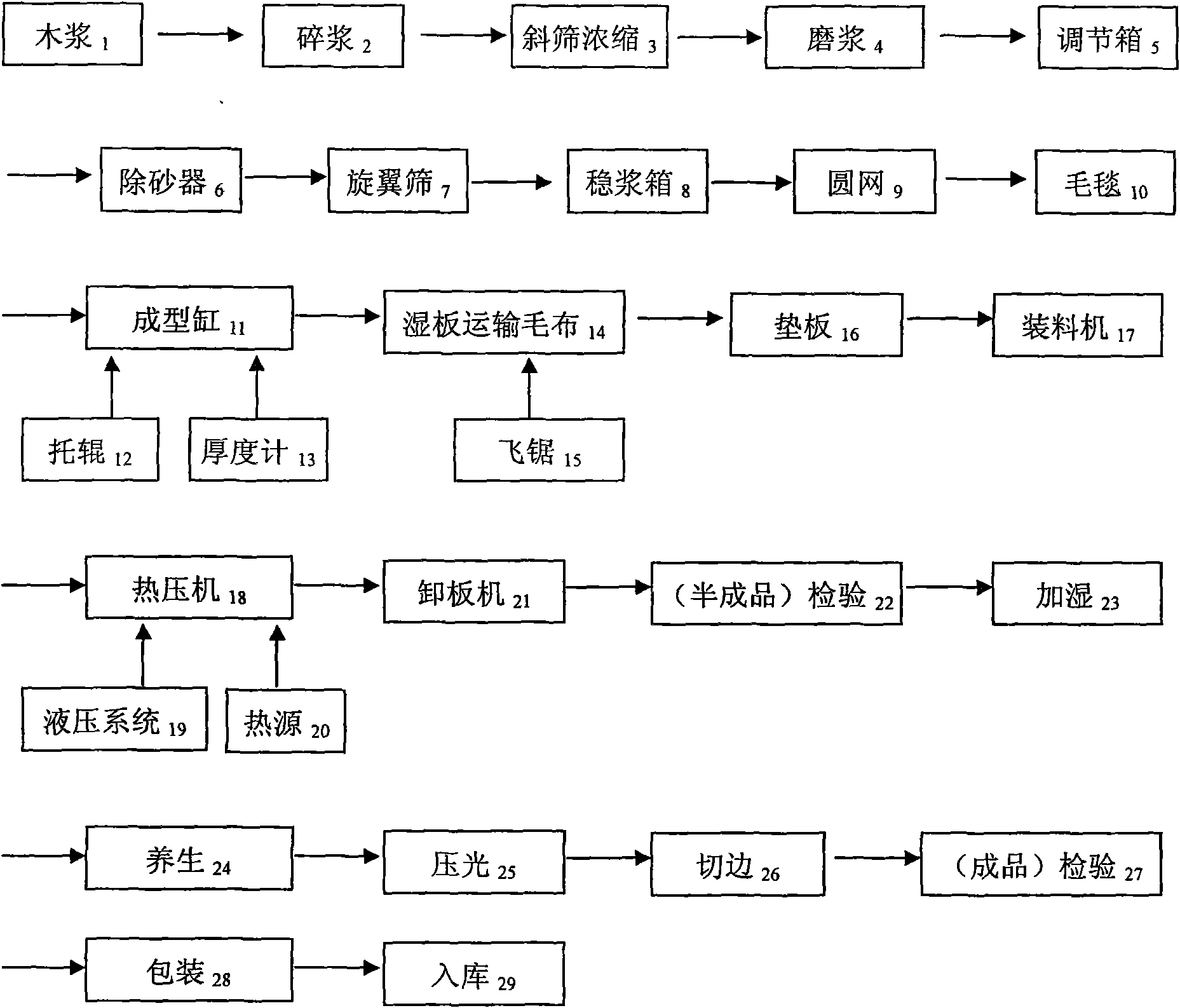

[0010] The wood pulp 1 is disintegrated into pulp 2, which is concentrated 3 by inclined sieve and then enters into pulp 4, the degree of beating is 36(40)°SR, and the wet weight is 10(14)g. After the pulp is adjusted by the adjustment box 5 to adjust the sizing amount and concentration, the sand remover 6, and the rotor screen 7 to remove the slag, it enters the pulp stabilization box 8 and flows into the circular screen 9, forming wet paper sheets that are adhered to the felt 10 and transported to the forming cylinder 11. The wet paper embryo runs circularly on the forming cylinder and is extruded and dehydrated by the idler roller 12 until the water content reaches 71 (75)%. Transfer to the wet plate transport felt 14, use the flying saw 15 to cut into a predetermined size, send it to the backing plate 16 equipped with metal mesh, enter the loading machine 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com