Cigarette static state throwing technique

A static and process technology, applied in tobacco, tobacco preparation, application, etc., can solve the problems of material moisture, temperature loss, unconfirmed accuracy, and complicated silk thread, so as to reduce temperature and humidity changes, easy to adjust and control, and flexibly adjust the process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

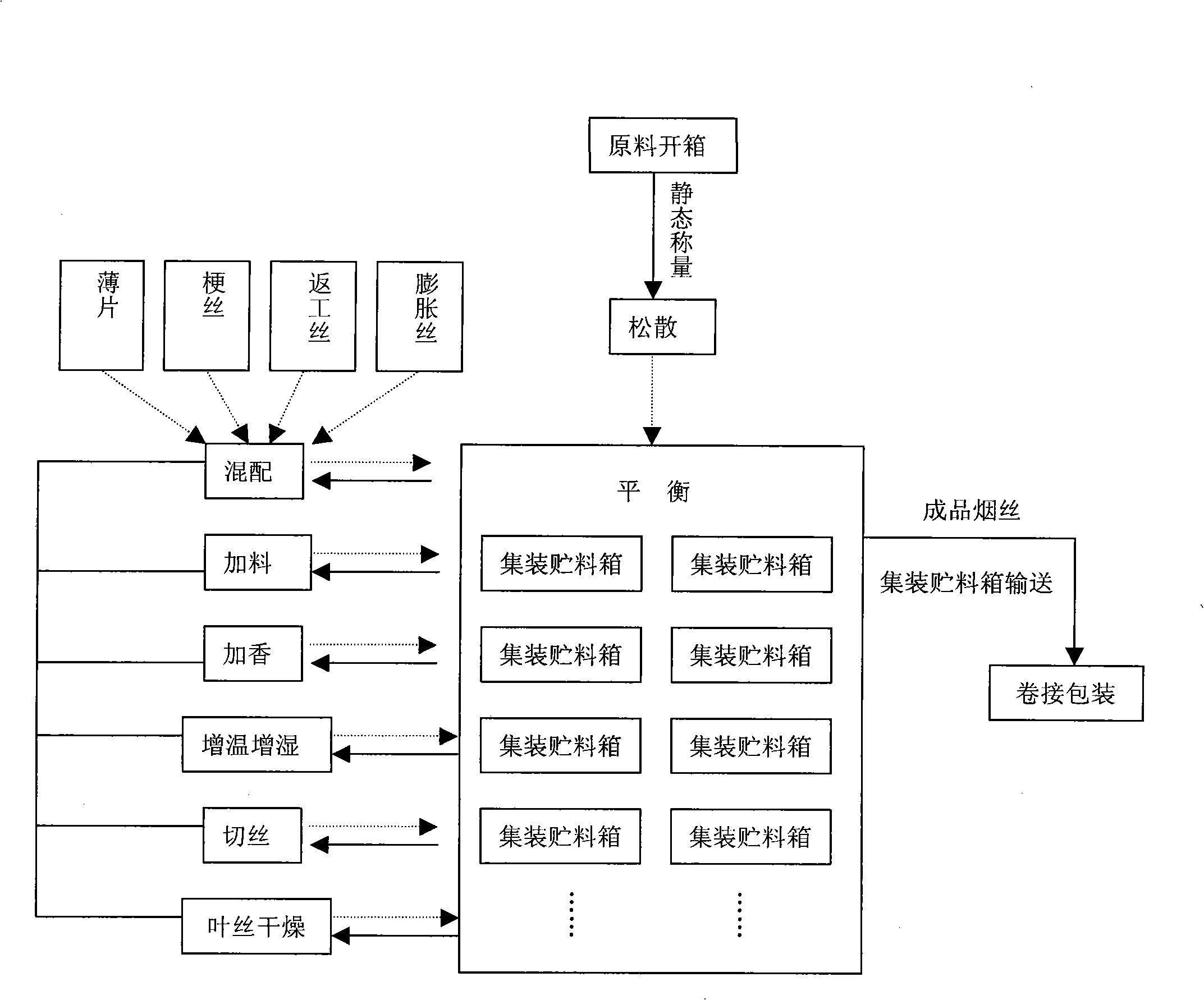

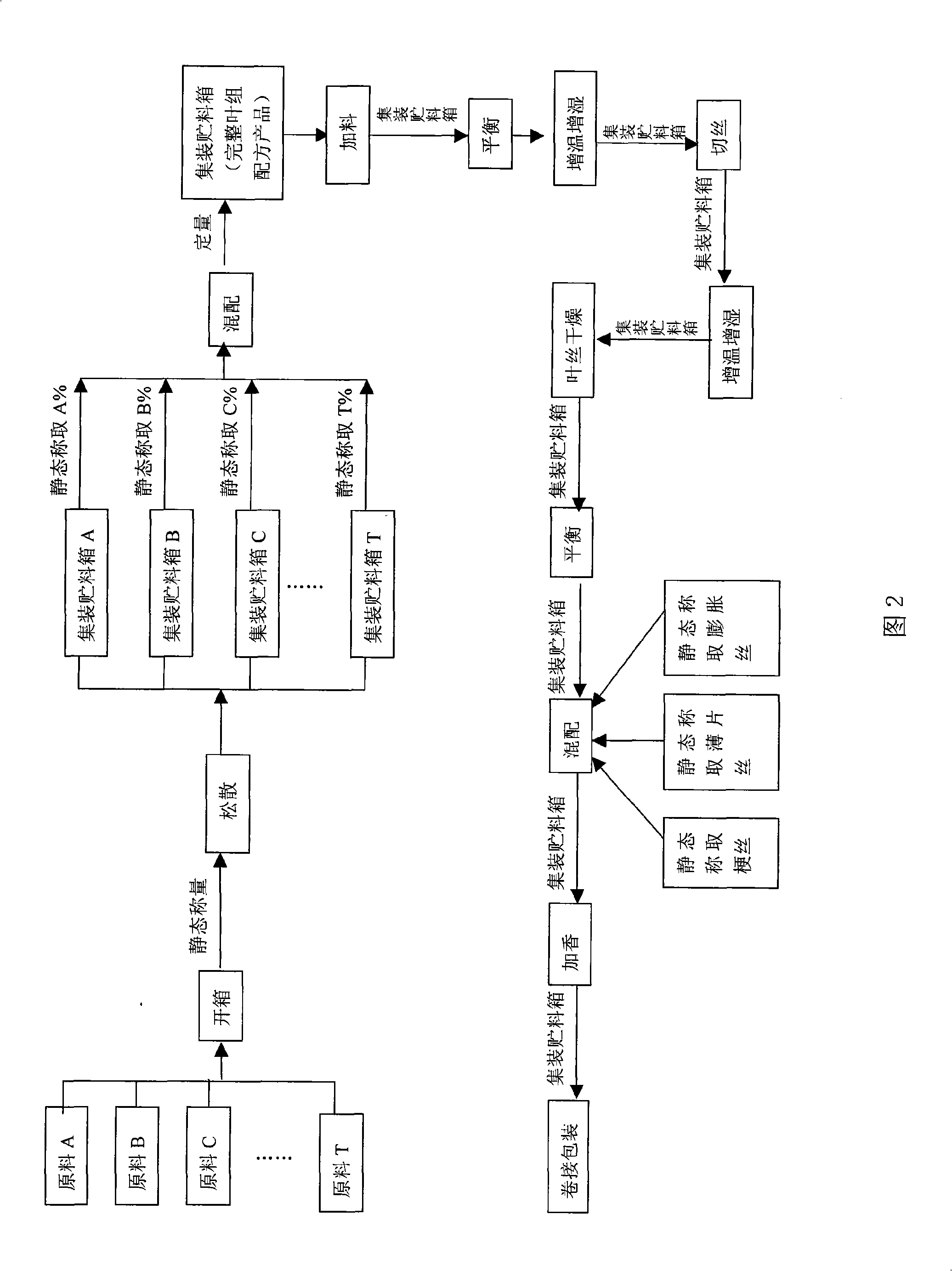

[0048] Embodiment 1: As shown in Figure 2, the container storage box, balance room and loosening, feeding and mixing equipment used in the cigarette static silk making process described in this embodiment are the same as the above, and the processing steps are as follows In order:

[0049] (1) According to the raw materials required by the formula, after unpacking the packaging boxes of 200kg re-cured sheet tobacco with different raw materials, they are respectively statically weighed, packed into container storage boxes and transported to a loosening device for loosening, and then separately Load into each container storage box and enter into the balance room for balance;

[0050] (2), take the tobacco leaves of the weight required by the formula ratio from each container storage box by static scales, put the tobacco leaves that have been weighed into the mixing device for mixing, and pack the tobacco leaves after mixing by 200kg quantitatively Container storage box to form ...

Embodiment 2

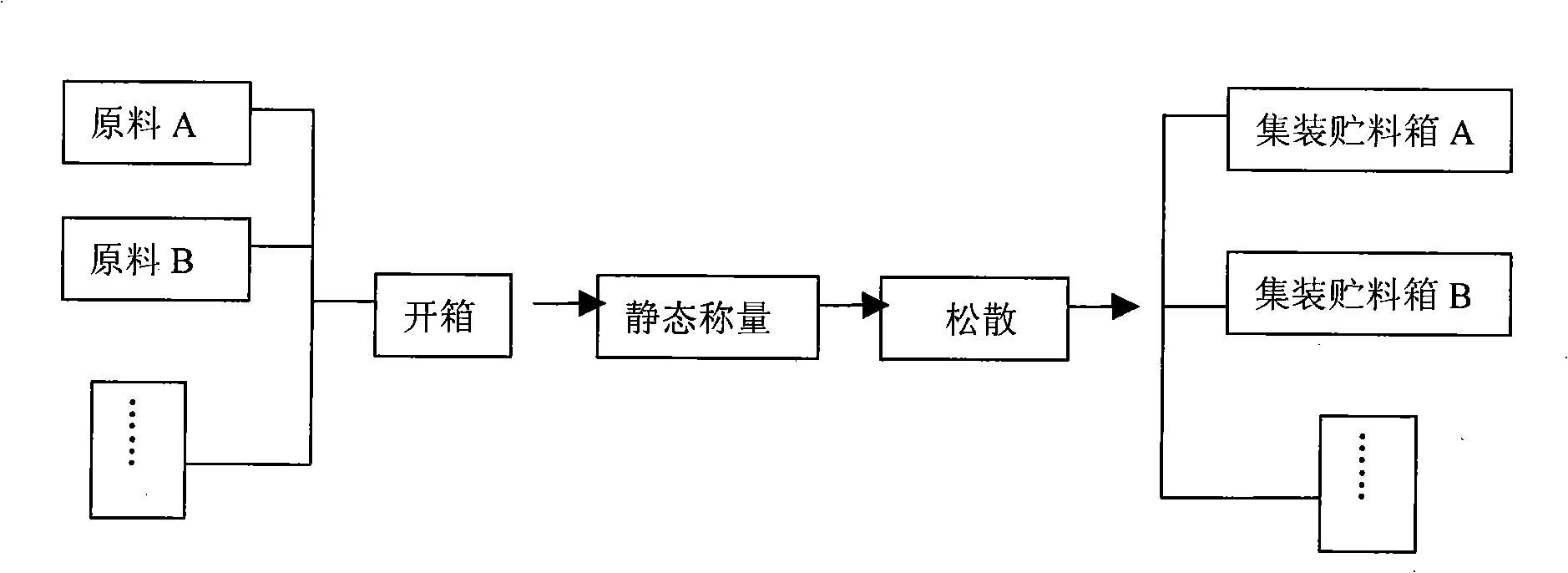

[0055] Embodiment 2: The static cigarette shredding process described in this embodiment adopts grouping processing and feeding by modules. The containerized storage tanks, loosening, feeding and mixing equipment used in the processing are the same as the above. Before processing, first establish a process library. The process library is to determine the corresponding processing technology and processing equipment for the product according to the design requirements of different products, and then integrate the various products and their corresponding processing technology and processing equipment. During production, first, according to the design requirements of the product to be processed, the processing technology and processing equipment of the product are determined through the process library, and the specific processing steps are carried out in the following order:

[0056] (1), such as image 3 As shown, according to the formula, after unpacking each package of 400kg r...

Embodiment 3

[0062] Embodiment 3: The container storage box, balance room, loosening, feeding and mixing equipment used in the cigarette static silk making process described in this embodiment are the same as in Embodiment 1, and the processing steps are also basically the same as in Embodiment 1. The difference is that after each loosening process, a balancing process is added, so that the internal and external moisture of the material is consistent, or the added essence and sugar can be absorbed evenly, providing conditions for the next step of processing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com