Pretreatment technology for reducing carbonization of tobacco stems after being expanded by microwave

A microwave expansion and pretreatment technology, applied in tobacco, tobacco preparation, application, etc., can solve the problems of carbonization of the core, poor expansion uniformity, processing characteristics of tobacco stem products and influence of smoking quality, etc. The effect of uniform temperature, improved cut stem quality and usage ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

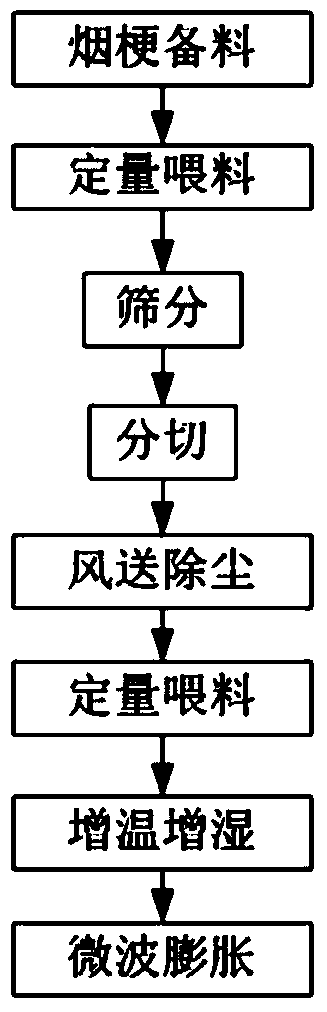

Image

Examples

Embodiment 1

[0018] The present invention is an improvement based on the present technology. The pretreatment process of the present invention for reducing carbonization of tobacco stems after microwave expansion includes the steps of tobacco stem preparation, feeding 1, screening, cutting, wind feeding, feeding 2, temperature increasing and humidifying, and microwave expansion. The equipment used in the present invention is purchased on the market.

[0019] The implementation process of the present invention is as follows:

[0020] a. The tobacco stems prepared according to the conventional method are controlled by an electronic belt scale to control the constant flow rate and enter the screening process; and the tobacco stems in the temperature increasing and humidifying process are controlled by an electronic belt scale to control the constant flow rate.

[0021] b. Tobacco stems are sieved by a vibrating sieving machine with a sieving aperture of 5 mm;

[0022] c. cutting the sieved ...

Embodiment 2

[0028] Process a, b, c, d are the same as embodiment 1. The differences are:

[0029] Tobacco stems enter the temperature increasing and humidifying process through the electronic belt scale to control the flow rate constant. Moisture is 14.5% by mass percentage.

[0030] The tobacco stems after the warming and humidification process enter the microwave expansion equipment, and the moisture content of the tobacco stems after the microwave expansion process is controlled to be 4.5% by mass.

Embodiment 3

[0032] Process a, b, c, d are the same as embodiment 1. The differences are:

[0033] Tobacco stems enter the heating and humidification process through electronic belt scales to control the flow rate to be constant. Moisture is 15% by mass percentage.

[0034] The tobacco stems after the warming and humidifying process enter the microwave expansion equipment, and the moisture content of the tobacco stems after the microwave expansion process is controlled to be 5% by mass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com