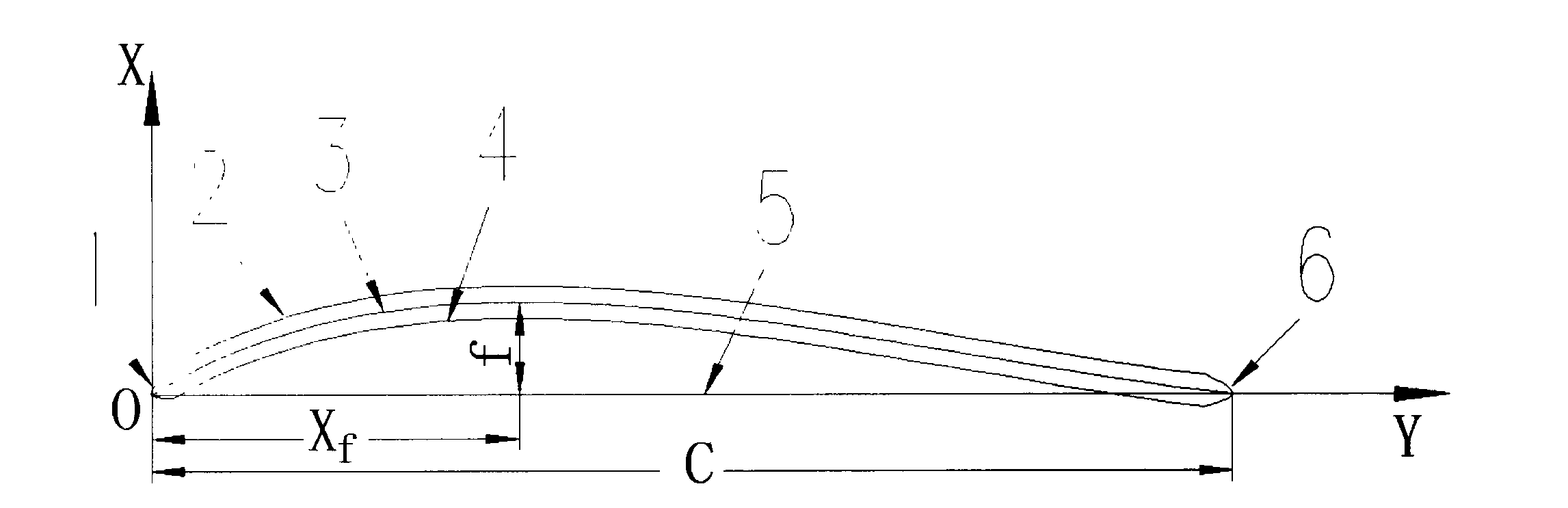

Variable-curvature arc equal-thickness plate wing section for fan group

A variable curvature, airfoil technology, applied in non-variable volume pumps, components of pumping devices for elastic fluids, machines/engines, etc., can solve problems such as poor matching, and achieve excellent matching and wind speed. High value, low noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

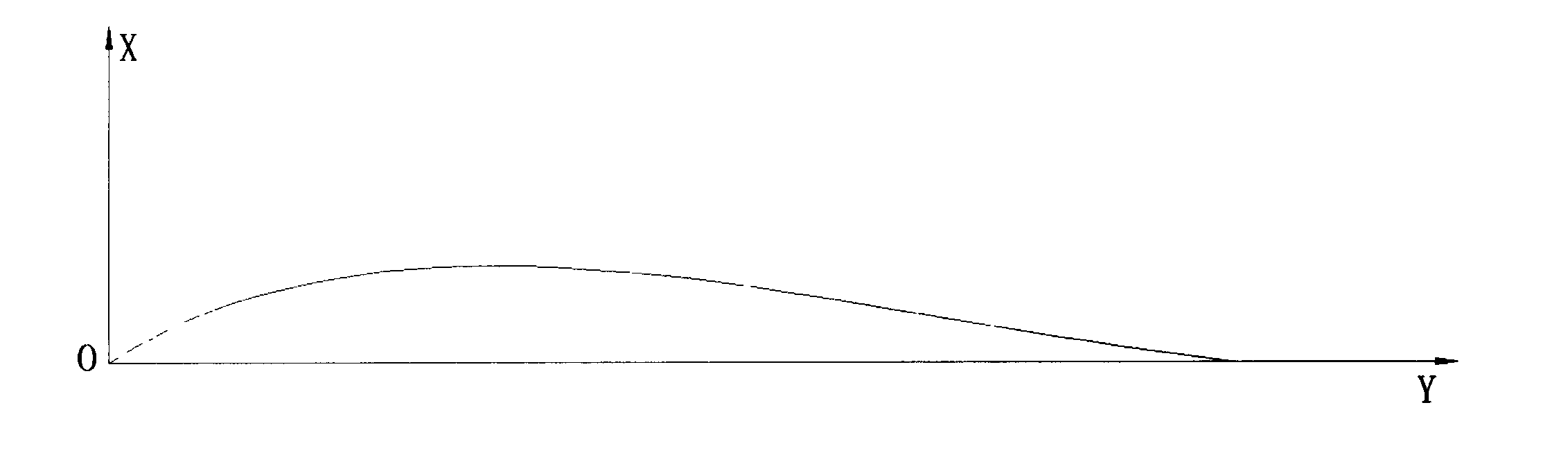

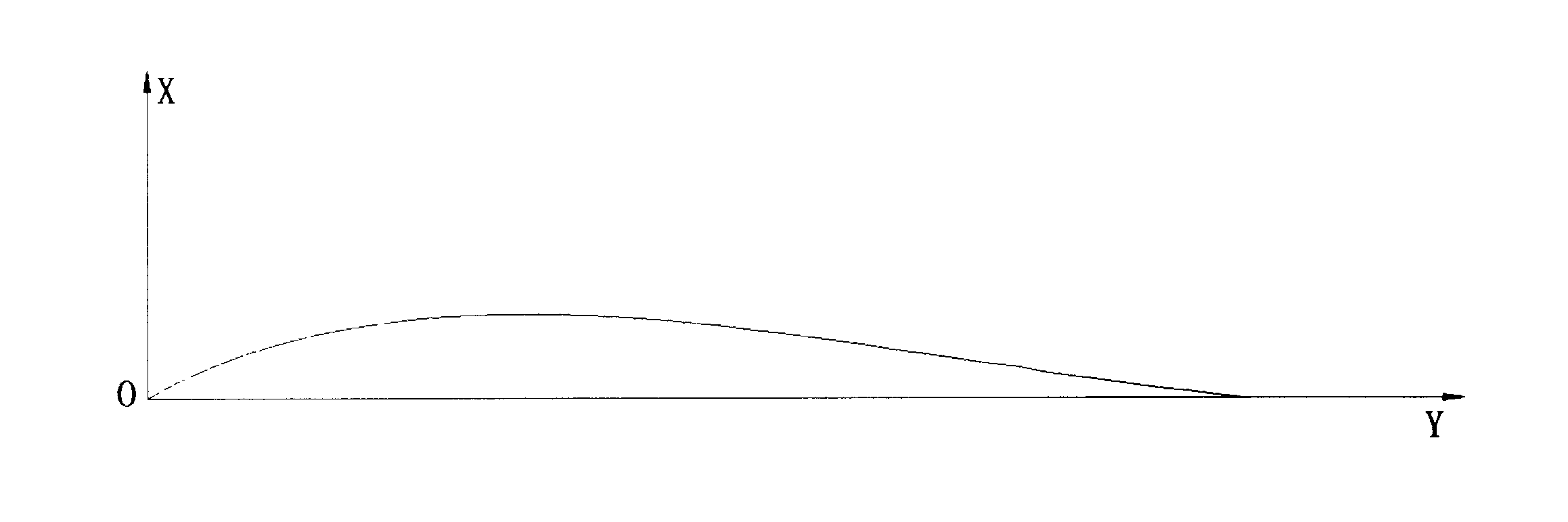

[0037] The accompanying drawings disclose an embodiment of the present invention in a non-limiting manner, and the technical solutions of the present invention will be described in detail below with reference to the accompanying drawings.

[0038] The design principle of a set of variable-curvature arc-shaped and equal-thickness plate airfoils for high-performance fans of the present invention is as follows: first, combined with the operating conditions of the low-speed fan, the aerodynamic analysis technology of the aviation industry is used to design a design that is compatible with the actual working conditions of the fan. Special airfoils for high-performance fans with good matching conditions. Since the main performance of the airfoil largely depends on the shape of its arc, especially the low-speed airfoil, through further research on the regular characteristics of the mid-arc of the airfoil specially designed for high-performance fans, and through theoretical analysis, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com