Pipeline structure for equally distributing purifying smoke pipe air quantity

A technology for smoke pipes and pipes, which is applied in the field of pipe structure for evenly purifying the air volume of smoke pipes, can solve the problems of drastic changes in the size and direction of the flow velocity, wear of the pipe wall, and high breaking rate of alumina particles, so as to avoid airflow turbulence and reduce The effect of tube wall wear and local pressure loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the embodiments.

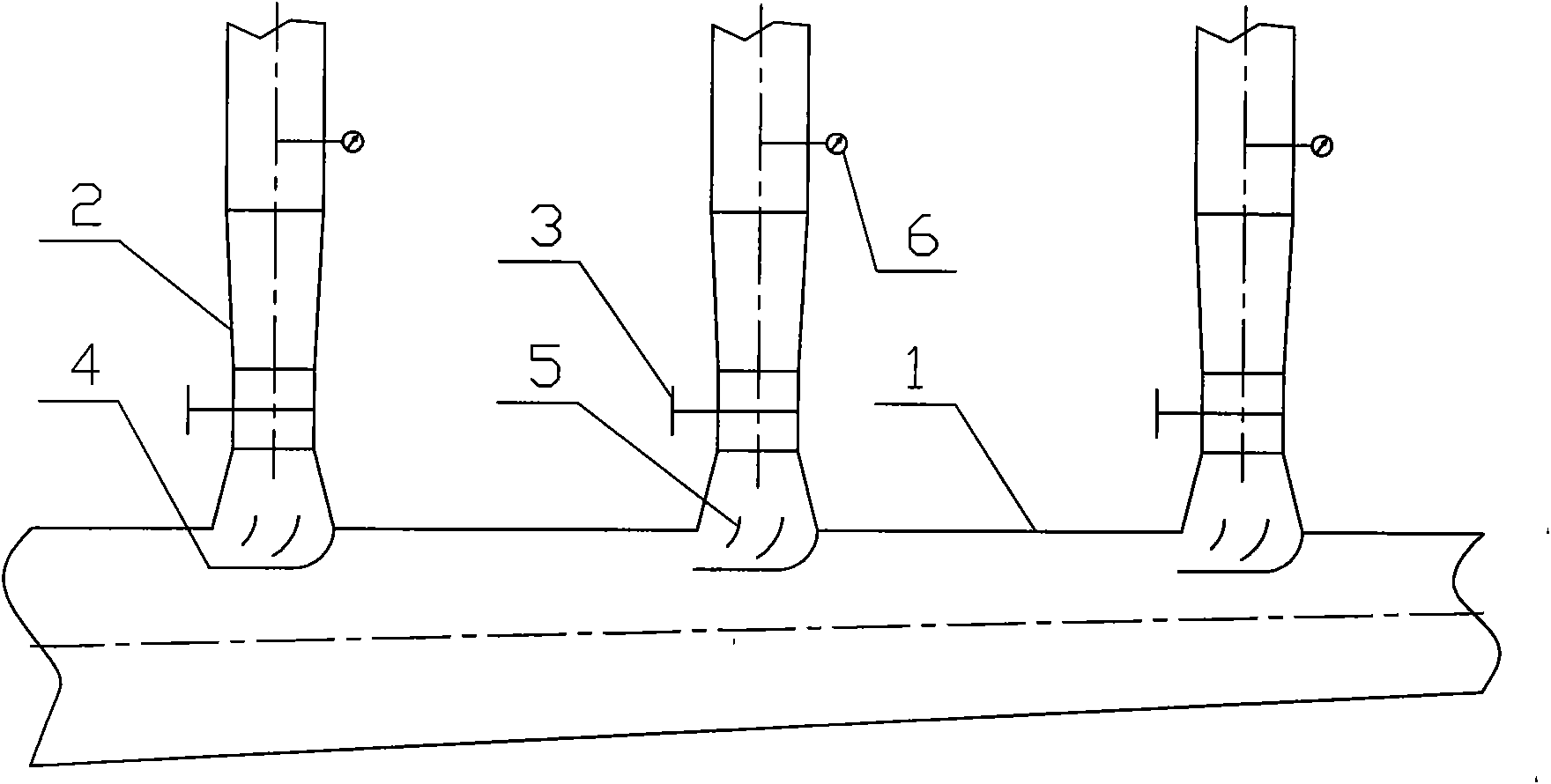

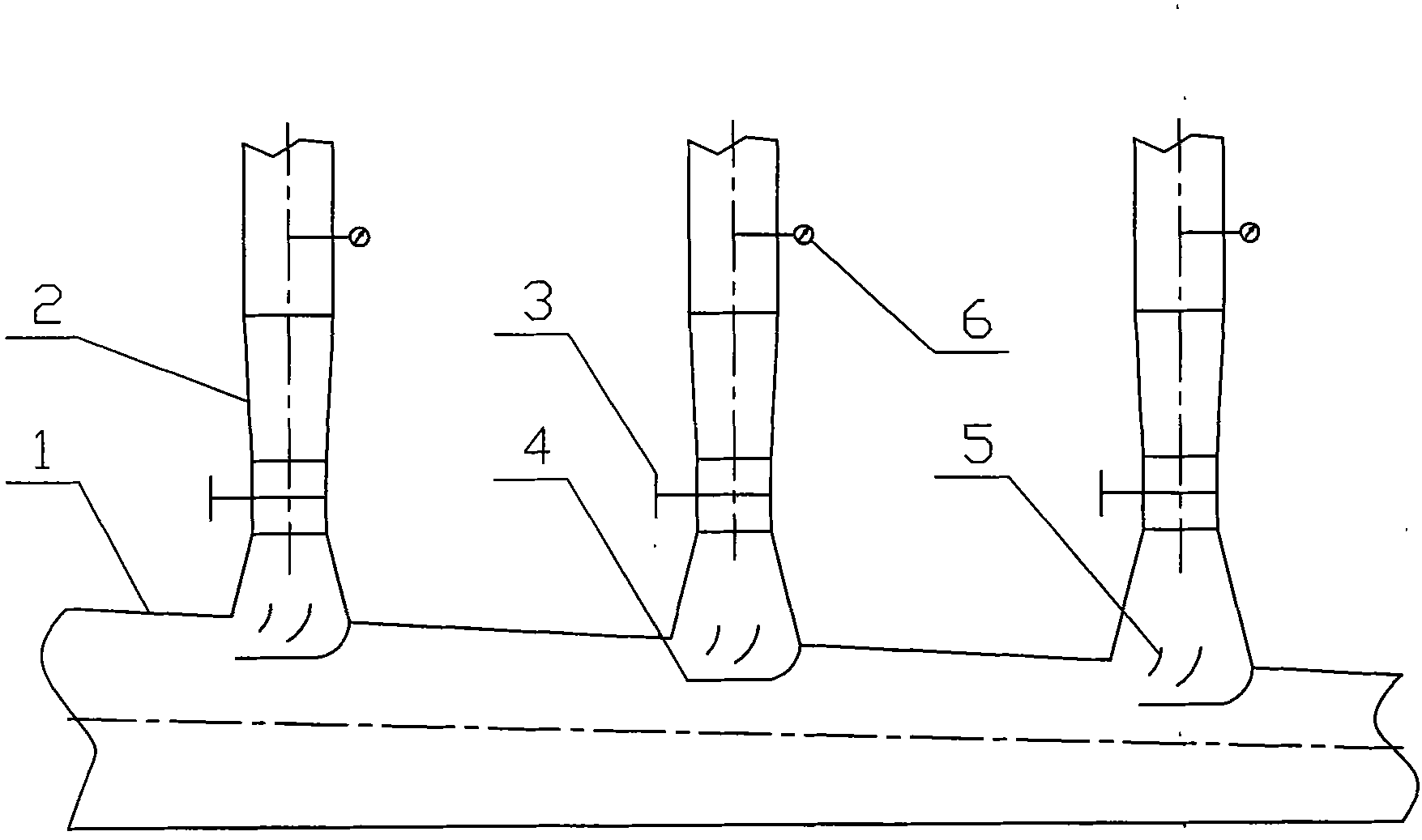

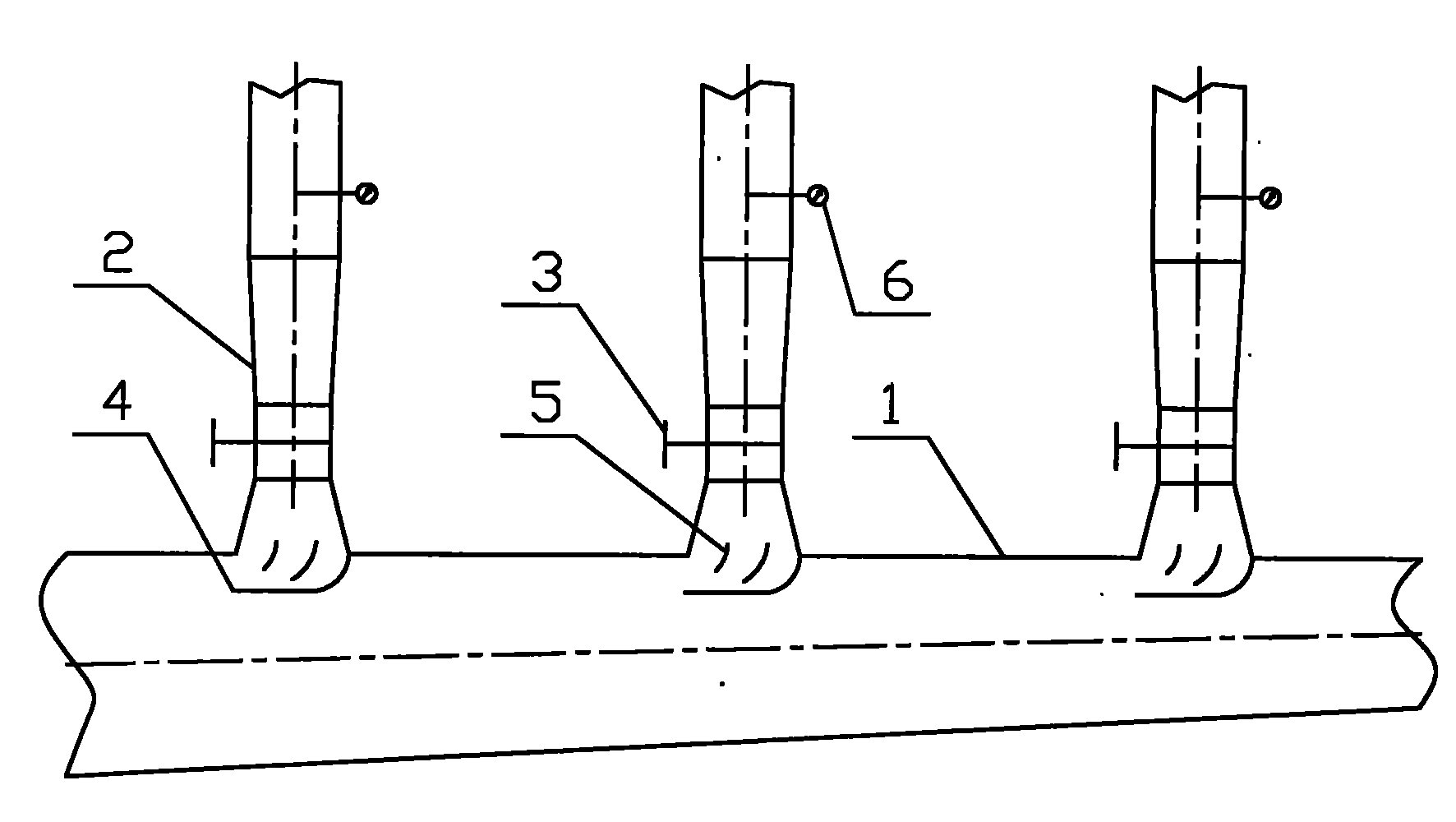

[0020] Such as figure 1 with figure 2 As shown, the pipeline structure of the present invention for evenly dividing the air volume of the purification smoke pipe includes the purification total smoke pipe 1, and at least two spacers 4 are arranged on the purification total smoke pipe 1, preferably 2 separate pipes are arranged on the purification total smoke pipe 1. -50 spacer tubes 4, intercepting the flue gas evenly along the airflow direction, the outlet of the spacer tubes 4 is connected to the reactor 2, the control valve 3 is arranged on the spacer tubes 4, and the spacer tubes 4 are set at the flue gas outlet in the main purification pipe 1 Facing the direction of flue gas flow, there is a deflector 5 inside the flue gas outlet, the spacer 4 and the deflector 5 are fixedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com