Method for making air inflows of secondary air pipes of turbulent burner even and measuring device

A swirl burner and secondary air duct technology, applied in the combustion method, burner, burner for burning powder fuel, etc., can solve the problems of uneven pressure, uneven secondary air volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical features and effects of the present invention more obvious, the technical solutions of the present invention will be further described below in conjunction with the accompanying drawings. The present invention can also be described or implemented with other different specific examples. Any person skilled in the art is within the scope of the claims. Equivalent transformations made within all belong to the protection scope of the present invention.

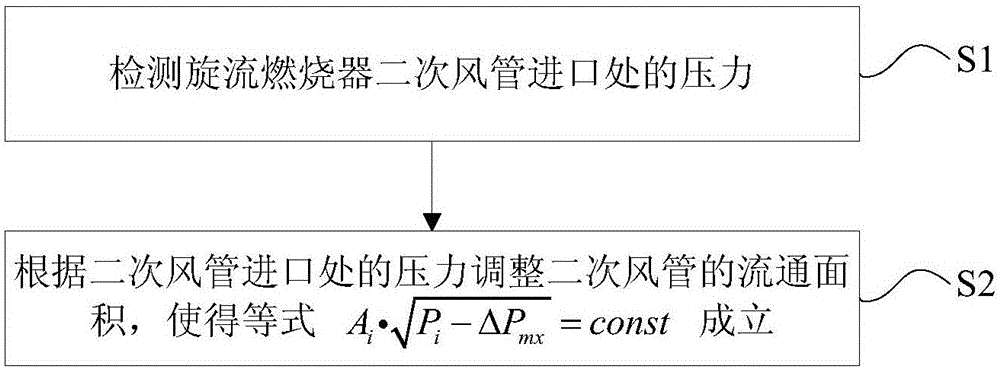

[0031] like figure 1 As shown, it is a flow chart of a method for uniformizing the air intake volume of the secondary air duct of a swirl burner according to an embodiment of the present invention, and the method includes:

[0032] Step S1: Detecting the pressure at the inlet of the secondary air duct of the swirl burner. Specifically, the pressure at the inlet of the secondary air duct of the swirl burner is detected by installing a pressure sensor (such as a micromanometer) at the inlet of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com