Leaf storage cabinet

A leaf storage cabinet and cabinet body technology, applied in the field of leaf storage cabinets, can solve the problems of inability to guarantee the temperature and humidity of materials in the leaf storage cabinet, serious temperature and humidity stratification, etc., to avoid heat and moisture exchange, direct temperature and humidity control, and uniform air volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

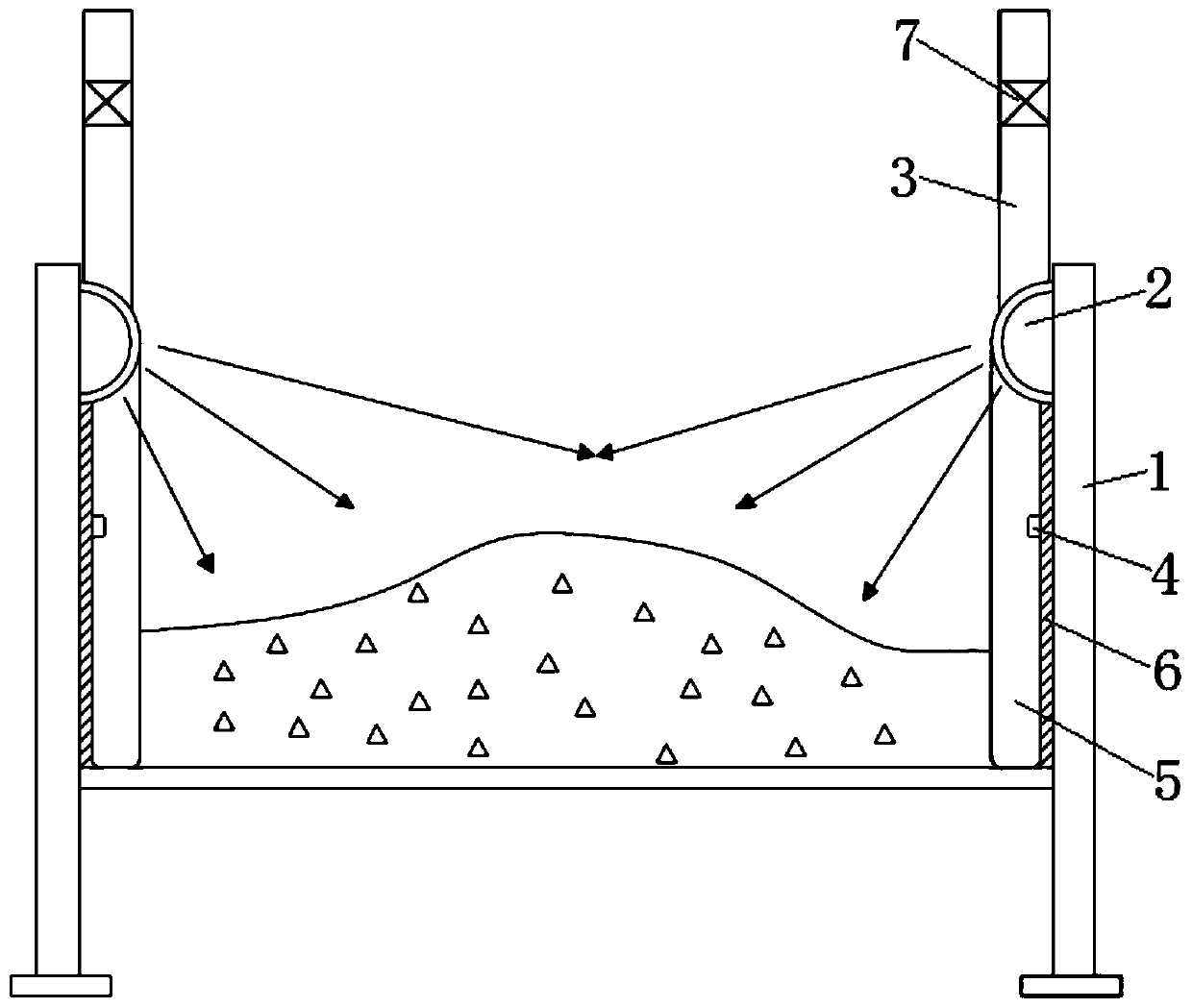

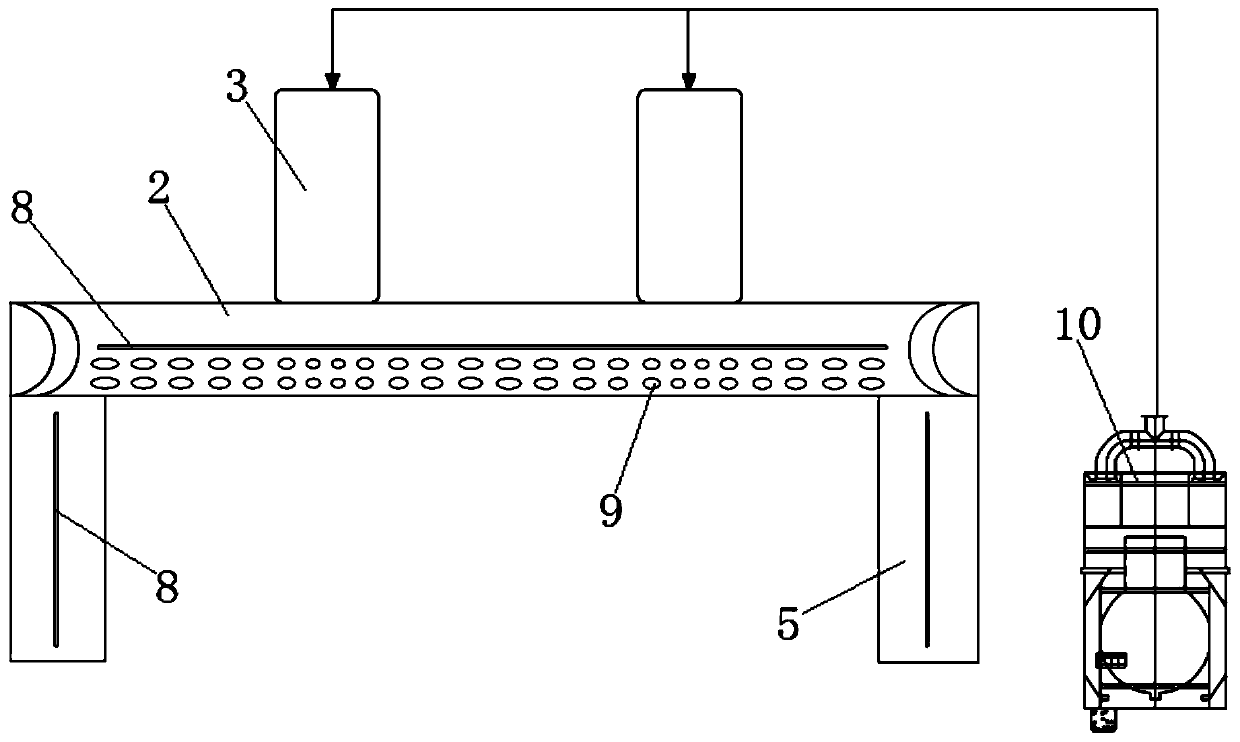

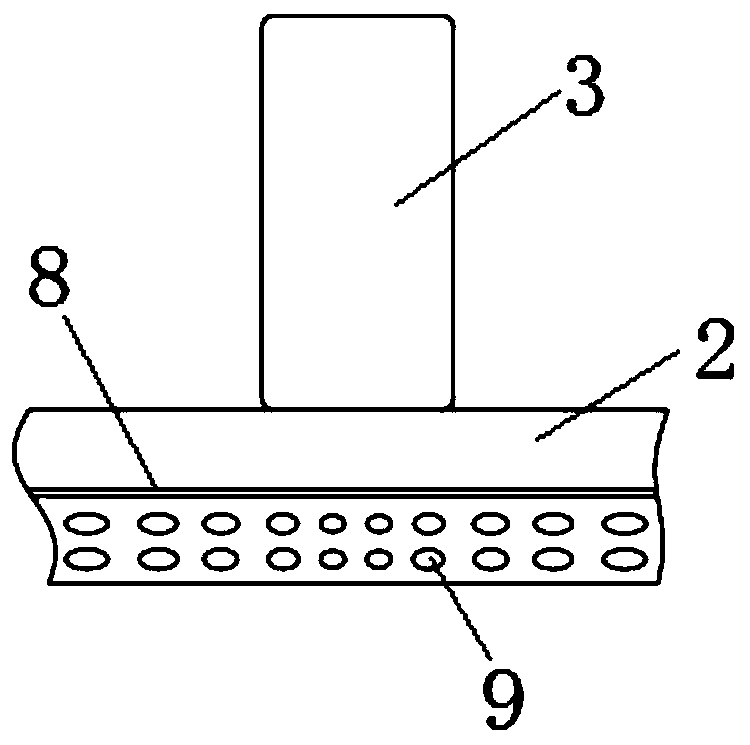

[0039] The present embodiment provides a kind of leaf locker, such as figure 1 As shown, it includes a cabinet body 1 , at least one first air supply pipe 2 , a connecting pipe 3 and a temperature and humidity detector 4 . In this embodiment, two first air supply pipes 2 are provided, which are oppositely arranged on two opposite inner walls of the cabinet body 1 and located above the materials. The two first air supply pipes 2 are arranged along the horizontal direction, and the length of the first air supply pipes 2 is consistent with the length on the side inner wall of the cabinet body 1 . Each first air supply pipe 2 is provided with a first air outlet, and the air outlet direction of the first air outlet is set at an angle with the inner wall where the first air supply pipe 2 is installed. In this embodiment, the first air outlet includes a strip Slit tuyere 8 and several micro-hole tuyere 9, slit tuyere 8 is opened on the first air supply pipe 2 along the extending dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com