Art paper coating machine

A technology of coating machine and coated paper, applied in the direction of physical processing of paper, etc., can solve the problems of high production cost, high labor intensity of manual operation, inability to quickly combine and separate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

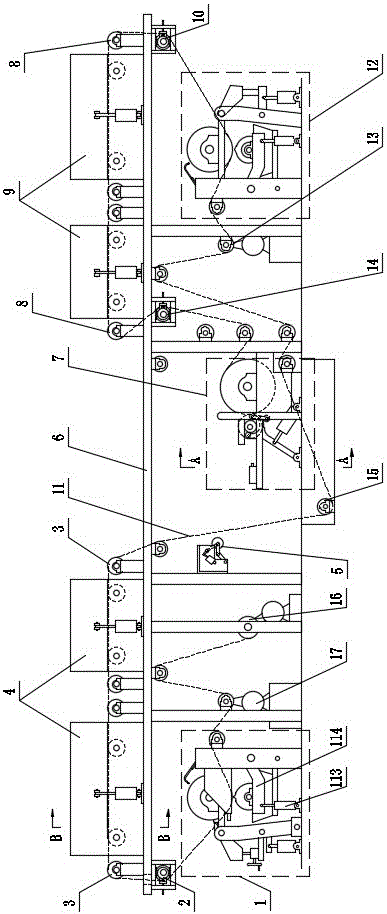

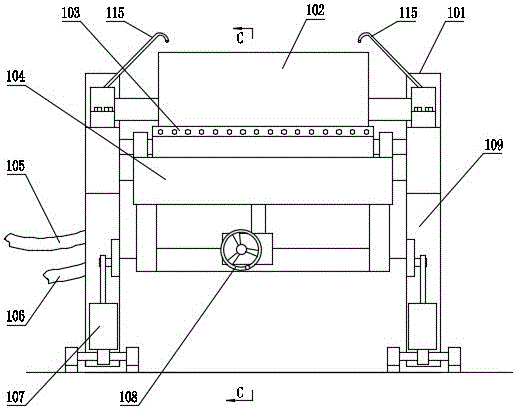

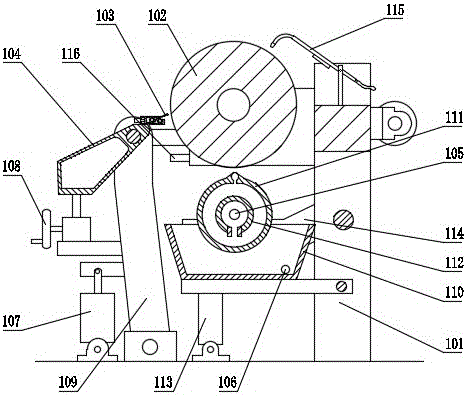

[0019] Referring to the accompanying drawings, the coated paper coating machine includes a dryer installed above the frame 6, a coating machine placed below the frame, and the coating machine is divided into a first coating machine 1 and a second coating machine 12 Two groups, the two groups of coating machines have the same structure, and are relatively arranged at the two ends below the frame. The first coating machine 1 or the second coating machine 12 includes a coating machine frame 101, and the coating machine frame 101 is equipped with The coating roller 102 driven by the power unit, the coating roller 102 below is provided with the coating tank 110 that is communicated with the material tank through the return pipe 106, and the coating tank 110 is connected on the coating machine frame 101 by a brace, and the coating tank 110 The top is provided with a paint spray barrel 111 driven by a lifting device, and the top of the paint spray barrel 111 is provided with a sprayin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com