Air inlet rice mill with double air sources

A rice mill and air inlet technology, applied in the field of rice mills, can solve the problems of large air inlet resistance, large difference in air inlet volume, long axial dimension, etc., and achieves reduction of loss along the process, balanced air volume and good stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

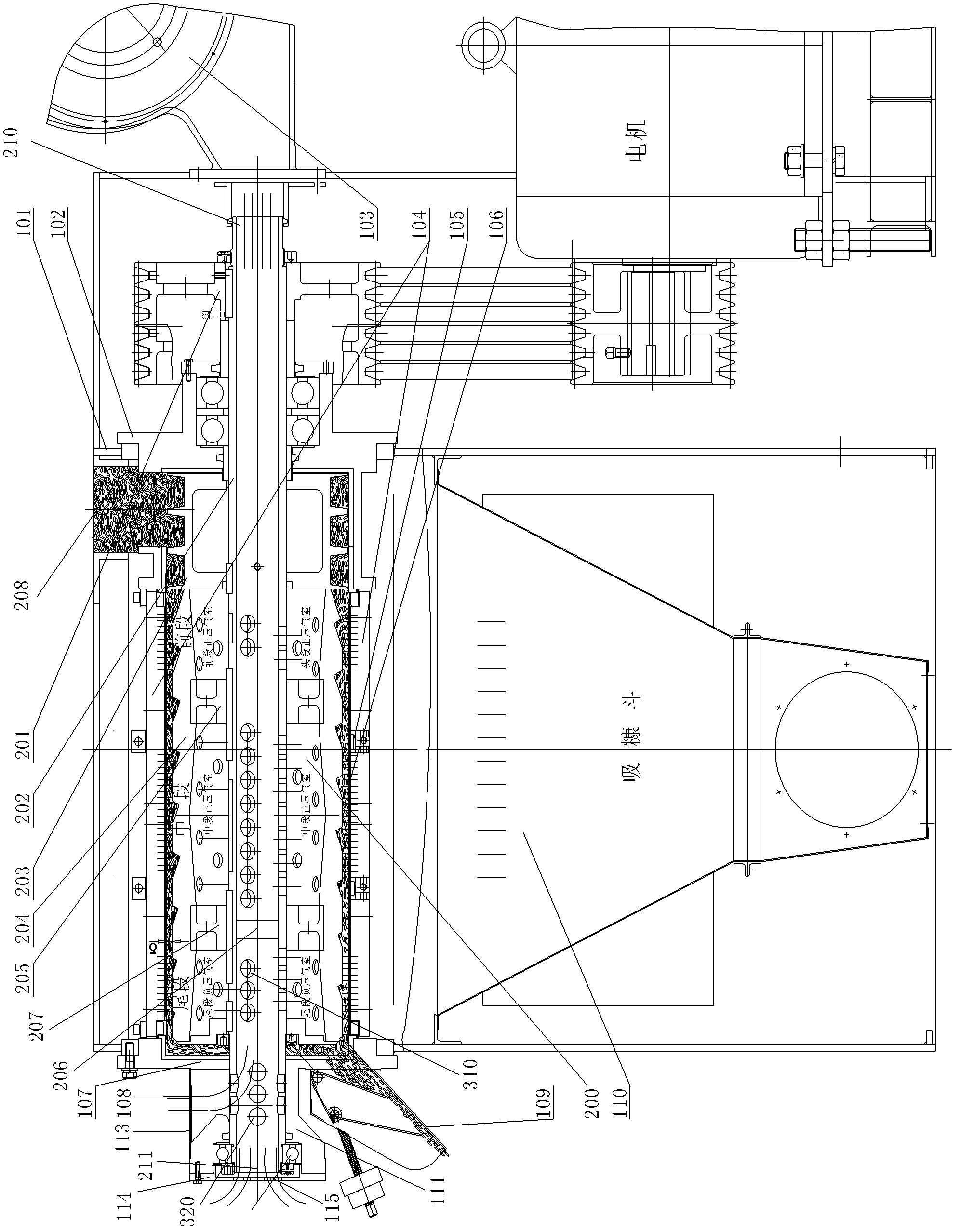

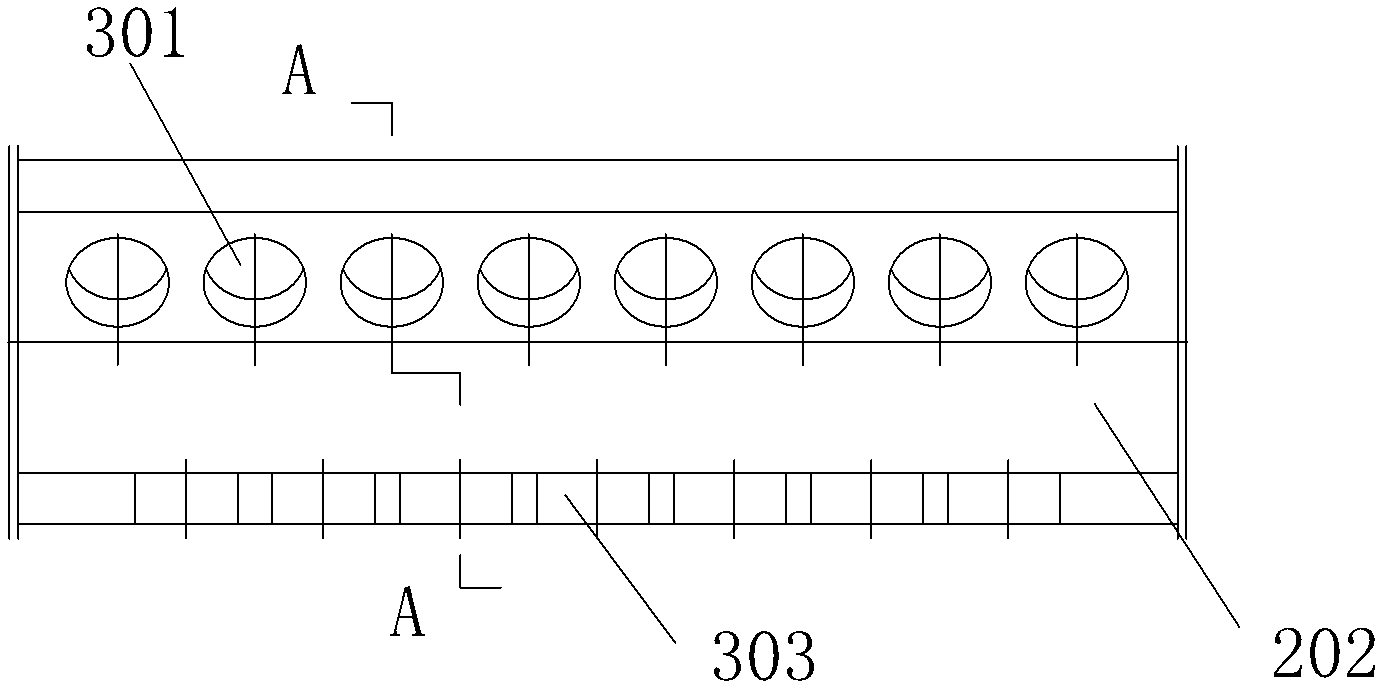

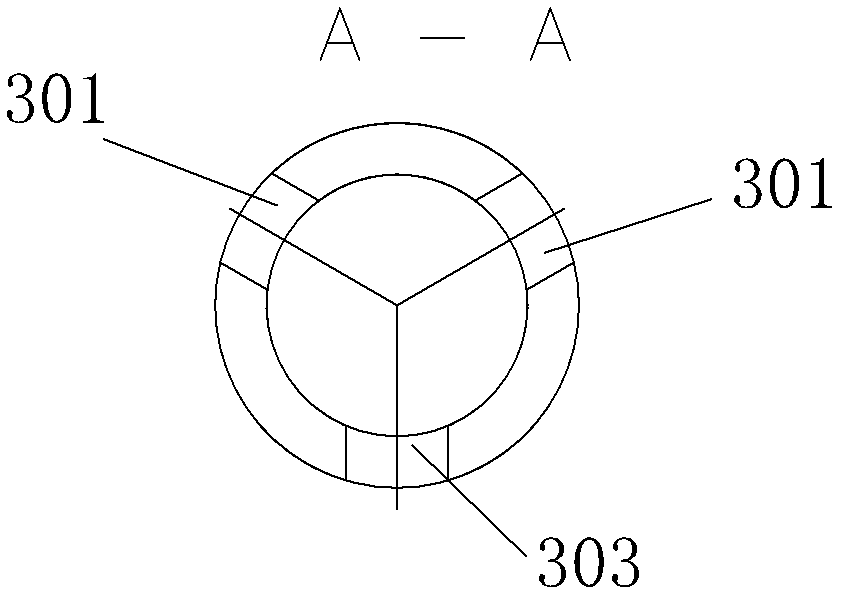

[0022] Such as figure 1 As shown, the frame 101 is provided with a rice milling room mechanism 200, and the rice milling room mechanism of the frame is connected with a bran suction bucket 110, and the chaff suction bucket 110 is connected with the suction device. The rice milling chamber mechanism 200 includes a main shaft 202, the two ends of the main shaft 202 protrude from the frame 101, and the frame 101 is connected with a main shaft feed side bearing seat 102 and a main shaft discharge side support frame 111. The main shaft on the feeding side is connected with a transmission device 201, and the transmission device 201 is a motor belt transmission device. The frame 101 on the discharge side is connected with a rice milling discharge mechanism 109 .

[0023] The frame rice milling room mechanism also includes the feeding hopper 208 established on the frame, and the main shaft 202 corresponding to the feeding hopper 208 position is connected with the feeding mechanism (a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com