Drying room with movable air supply system

An air supply system and drying room technology, applied in the field of drying rooms, can solve the problems of uneven air volume in the drying room and dead ends of material ventilation, and achieve the effects of avoiding dead ends of ventilation, uniform air volume and improving drying efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

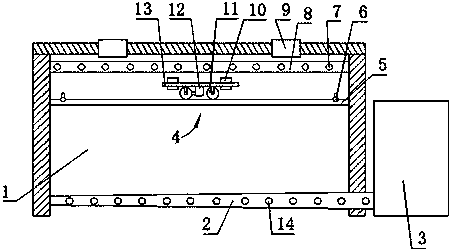

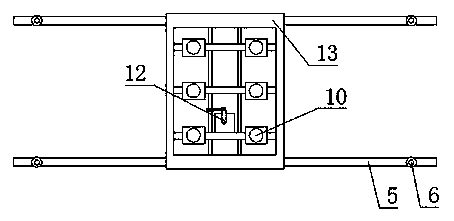

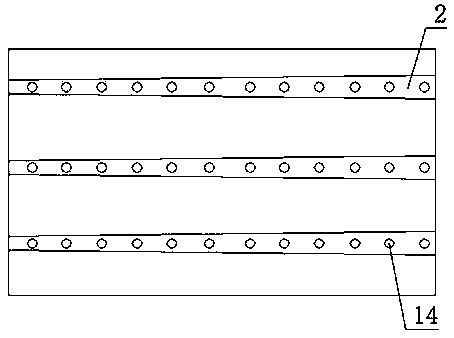

[0023] Such as figure 1 , figure 2 , image 3 As shown, the drying room with a movable air supply system includes a room body 1, and a plurality of air supply drying channels 2 and air outlet pipes 8 are installed in the room body 1, and the air supply drying channels 2 are connected with an air energy heat pump 3 to provide To ensure the hot air needed for baking the room body 1, there are multiple air inlets 14 and air outlets 7 on the outside of the air supply drying channel 2 and the air outlet pipe 8, which can be adjusted according to the size of the room body and the amount of materials to be baked in the room. Determine the opening number of air inlet 14 or air outlet 7. The air-supply drying tunnel 2 is arranged at the bottom of the room body, and the air outlet pipe 8 is arranged at the inside top of the room body. Because the hot air density is relatively small, this design helps the circulation of the hot air in the room. In order to make up for the defect t...

Embodiment 2

[0027] This embodiment differs from Implementation 1 in that, as Figure 4 , Figure 5 As shown, when the lateral span of the room body 1 of the drying room is relatively large, a lateral air supply system 15 for laterally moving the fan 10 is also provided above the frame 13, and the lateral air supply system 15 includes a small frame 16, a lateral Guide rail 20, transverse guide wheel 18, transverse guide rail 20 is fixed on the frame 13 lateral end edges, blower fan 10, transverse guide wheel 18 are fixed on the small frame 16. The small frame 16 is provided with rotational power by the lateral power system 17. Under the action of the lateral power system 17, the lateral guide wheels 18 run on the top of the horizontal guide rail 20 to drive the small frame 16 to move laterally, and are fixed on the two ends of the lateral guide rail 20. Limit switch 19 controls the travel stroke of small frame 16. Driven by the small frame 16 to move the blower fan 10 laterally back a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com