A sintered anti-blocking grate

A technology of grate and body, applied in the field of sintering equipment, can solve the problems of low utilization efficiency of sintering combustion air, low sintering production efficiency, low utilization rate of combustion air, etc., and achieves the effects of light weight, reduced weight and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

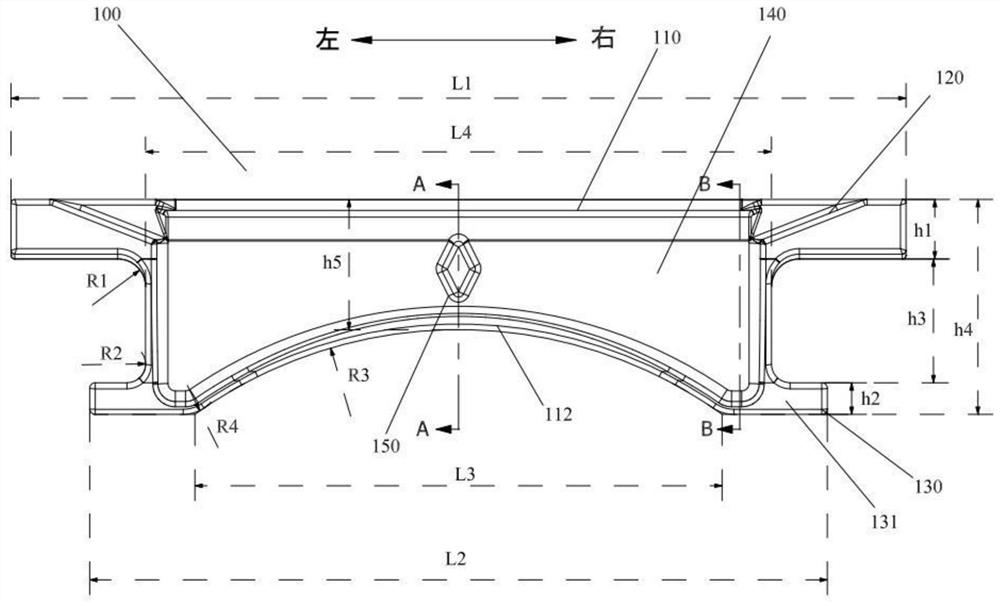

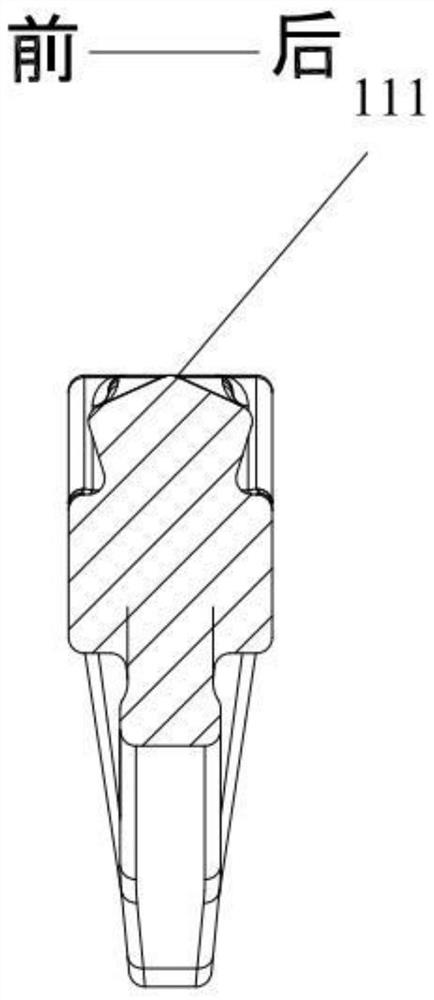

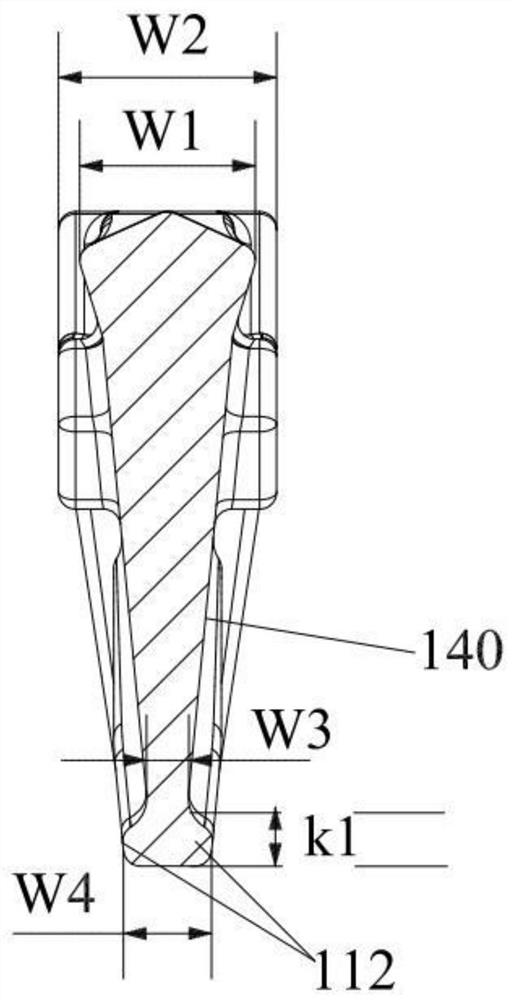

[0032] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. In explaining the embodiments of the present invention, if a detailed description of related well-known elements or functions interferes with the gist of the present invention, the detailed description will be omitted. The "thickness" of the present invention refers to the length marked in the front and rear directions in the drawings, and the "length" of the present invention refers to the length marked in the left and right directions in the drawings.

[0033] In describing the present invention, it should be understood that the terms "center", "longitudinal", "transverse", "length", "width", "thickness", "upper", "lower", "front", " Back", "Left", "Right", "Vertical", "Horizontal", "Top", "Bottom", "Inner", "Outer", "Clockwise", "Counterclockwise", "Axial" , "radial", "circumferential" and other indicated orientations or positional rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com