System for controlling variable air rate ventilating laboratory in segments

A ventilation system and segmented control technology, applied in the field of ventilation systems, can solve the problems of insufficient exhaust air volume, inability to accurately control the exhaust air volume of fume hoods, and the spread of pollutants, and achieve the effect of reducing exhaust noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

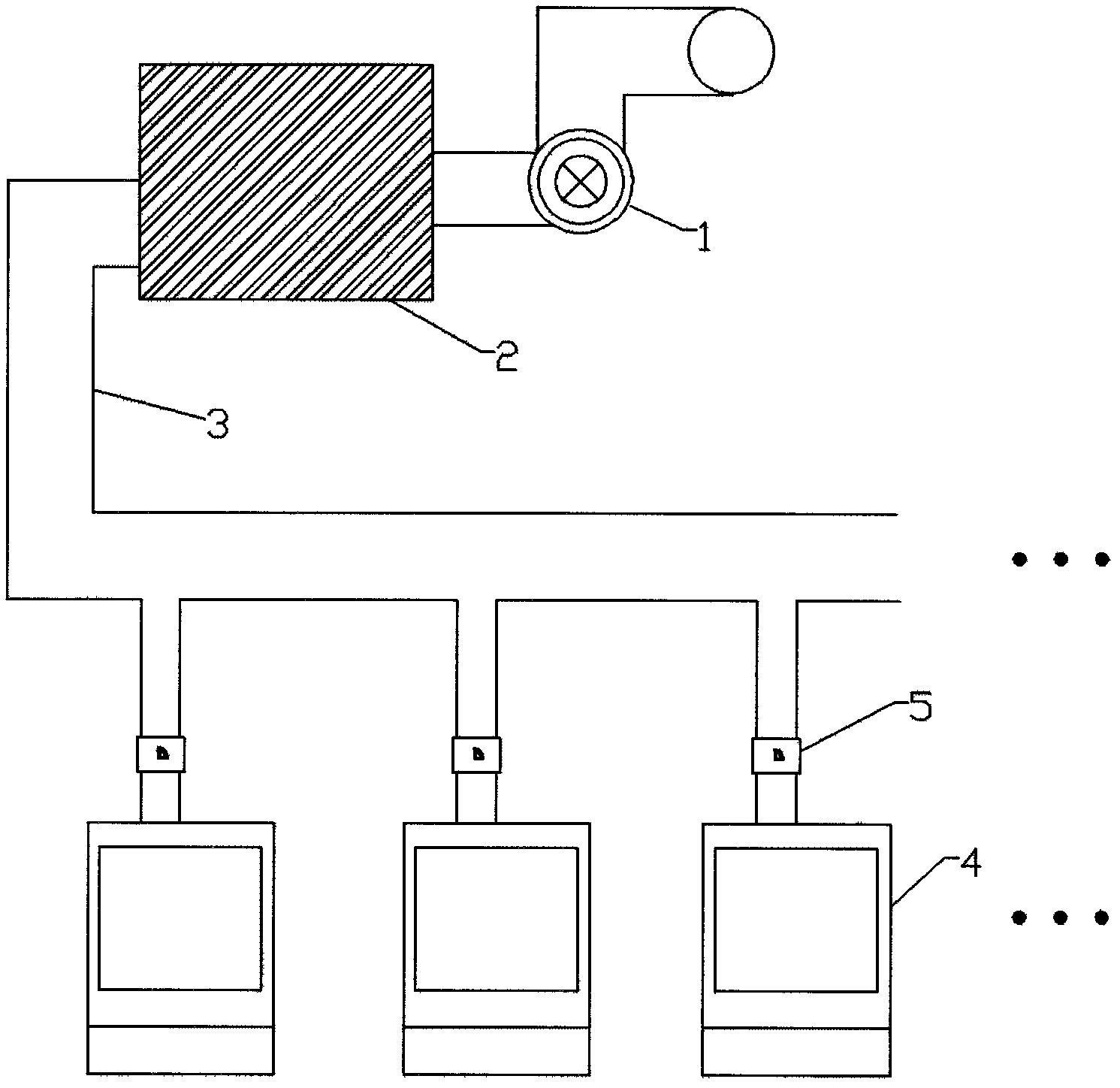

[0013] figure 1 It is a schematic diagram of a ventilation system in the prior art of a laboratory, which generally includes a variable frequency fan 1 connected to a plenum box 2, and the variable frequency fan and the plenum box are installed on the roof or outdoors. The plenum is connected to the main ventilation duct 3, which extends into the laboratory and communicates with each fume hood 4 through a plurality of branch ventilation ducts. In addition, a manual air valve 5 is installed at the end of the fume hood to control the exhaust air volume of the fume hood. In the ventilation system of this prior art, when a large number of fume hoods are opened, uneven air volume will inevitably occur, resulting in a strong exhaust air volume of the fume hood near the main ventilation duct, and insufficient exhaust air volume of the fume hood far from the main ventilation duct. .

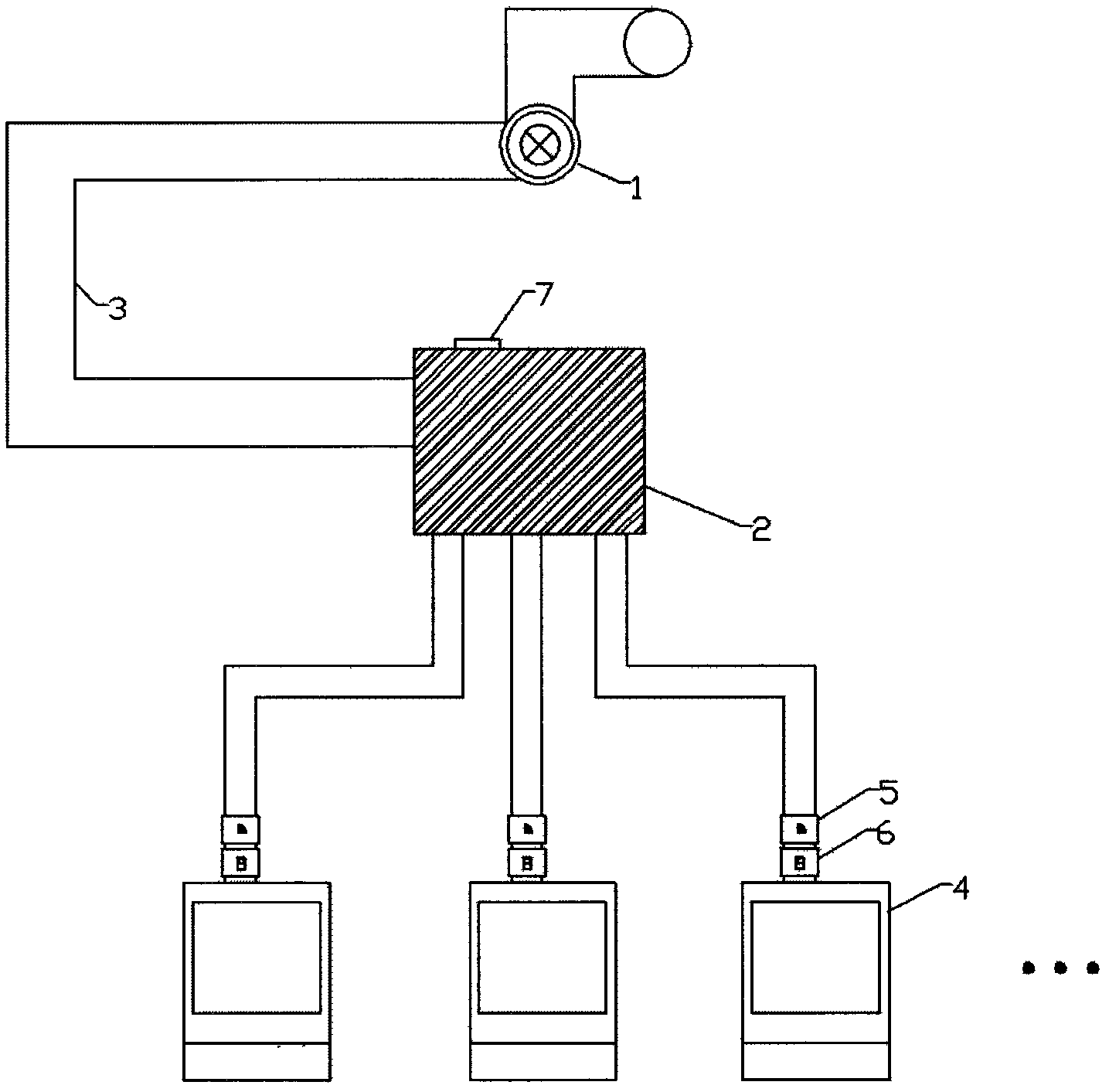

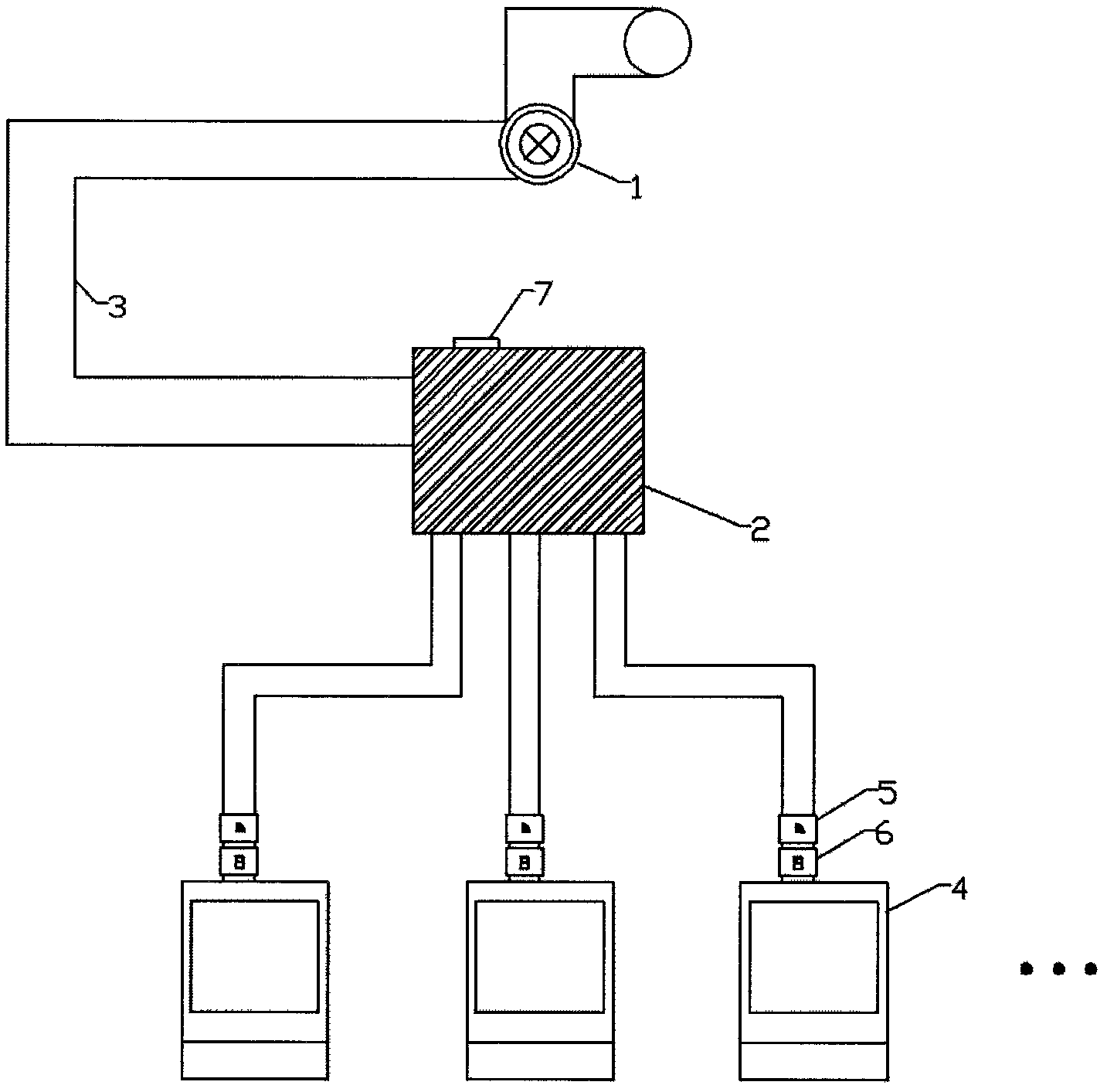

[0014] Therefore, in the design of the laboratory ventilation system, the present invention propose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com