Movable bed device for recovering sensible heat of high-temperature bulk materials

A moving bed and bulk material technology, applied in recycling technology, waste heat treatment, lighting and heating equipment, etc., can solve the problems of semi-molten slag particles not easy to return to heat, waste heat resources, etc., to improve the glass body conversion rate, prevent slag The effect of pellet reheating and reduction of fan power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

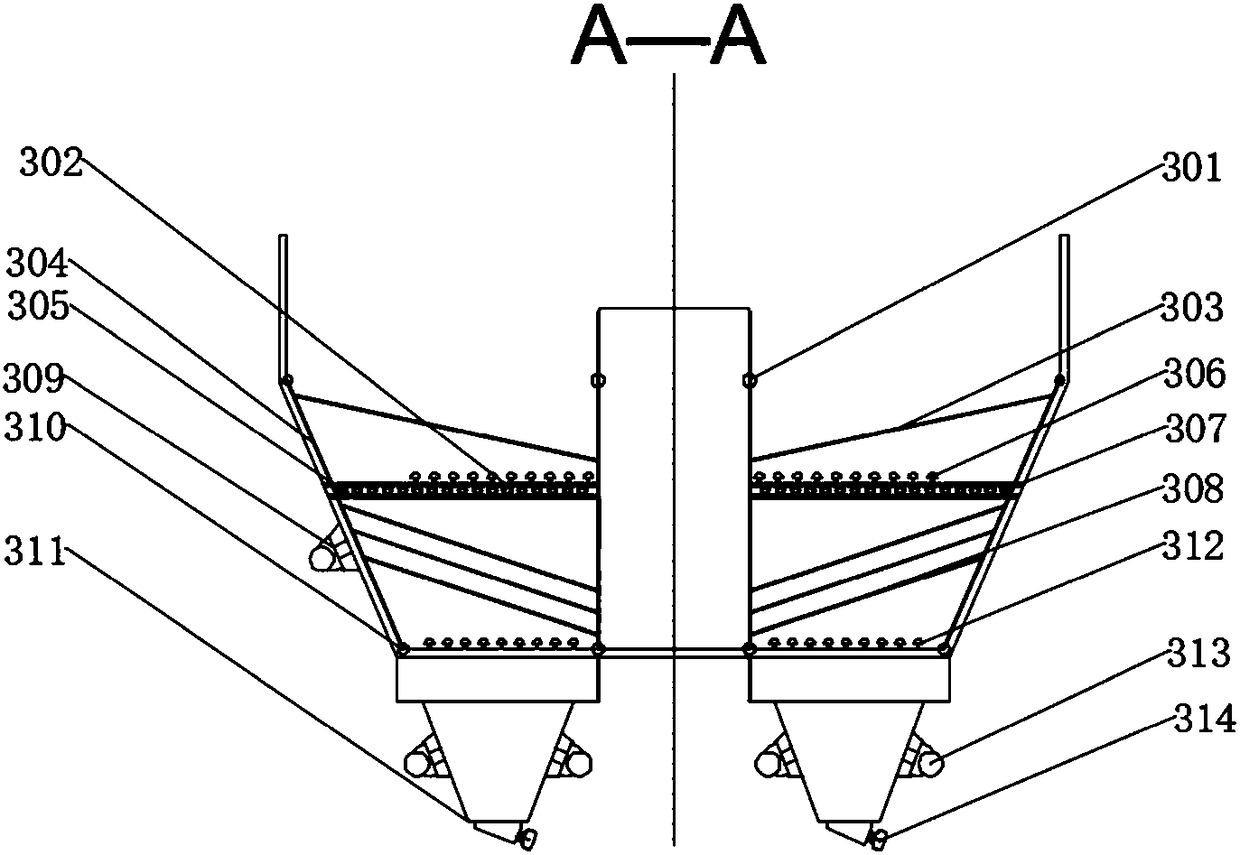

[0030] see Figure 1 to Figure 4 As shown, the present invention is a moving bed device for recovering sensible heat of high-temperature bulk materials, including a moving bed; the moving bed includes a cooling wall surface 304 and a receiving bin 311;

[0031] The cooling wall surface 304 is arranged at the lower part of the granulation chamber, which is used to accommodate the high-temperature slag particles granulated by the granulator; the cooling wall surface 304 surrounds and forms two symmetrical accommodating cavities with a large top and a small bottom; the two accommodating cavities Separated by the middle furnace wall; there is a granulator installation space in the middle furnace wall.

[0032] A receiving bin 311 is provided at the bottom of the conical accommodating chamber, and a rotary sealing valve 314 is provided at the bottom of the receiving bin 311 . The outer wall of the receiving bin 311 is provided with a vibration block 313 .

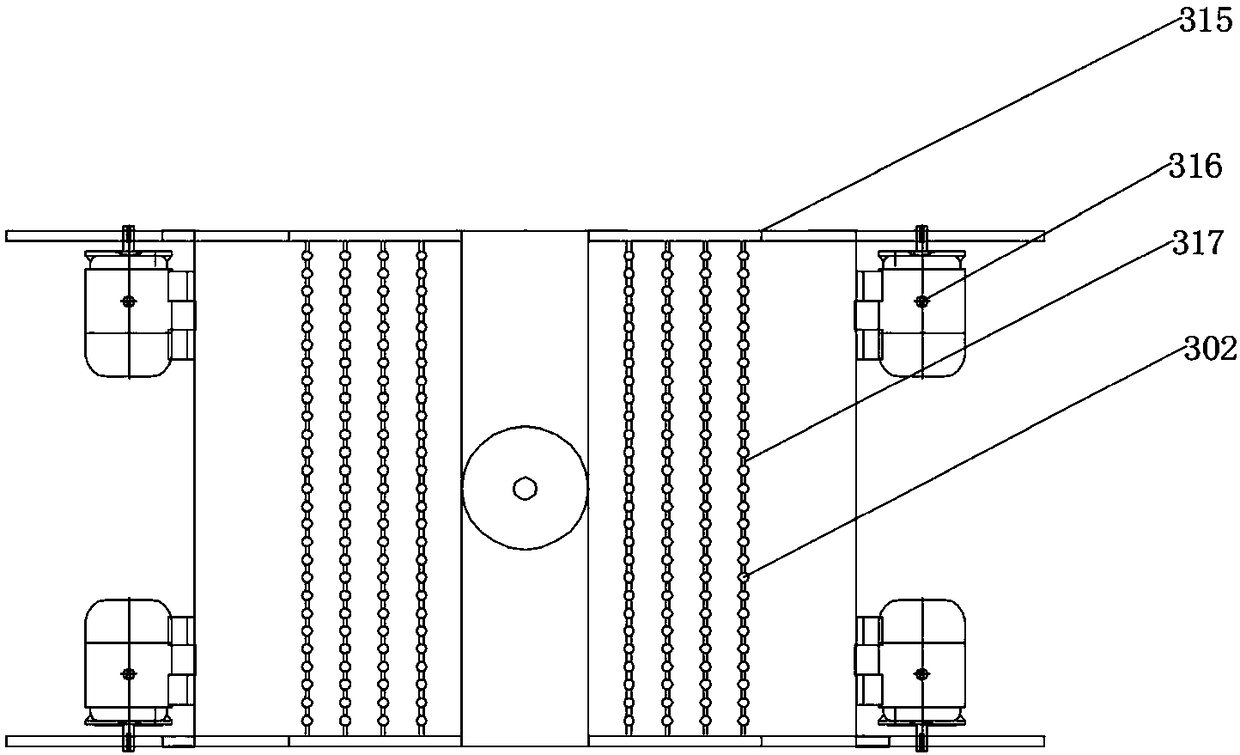

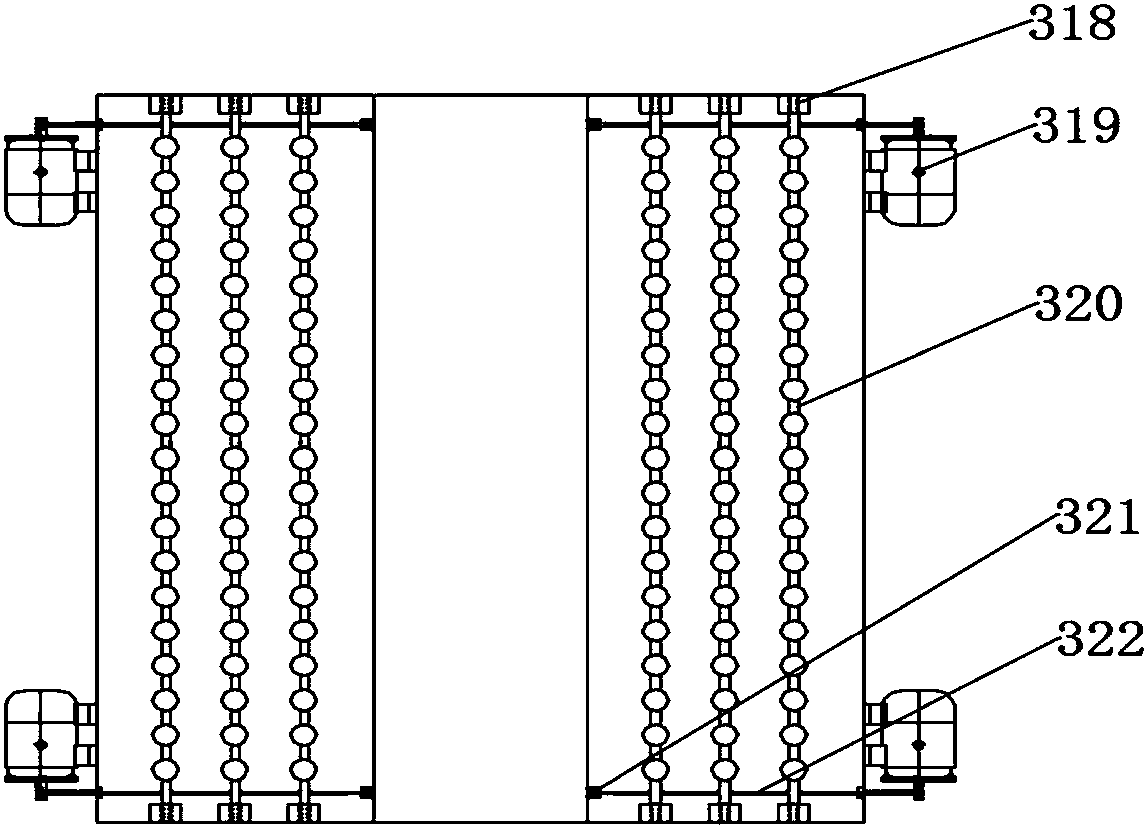

[0033] Dilute-phase ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com