Heat exchanger and vertical type air conditioner provided with same

A vertical air conditioner and heat exchanger technology, which is applied in the field of vertical air conditioners, can solve the problems such as the inability of the heat exchanger to fully utilize the space, and achieve the effects of simple structure, sufficient contact, and increased heat exchange speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

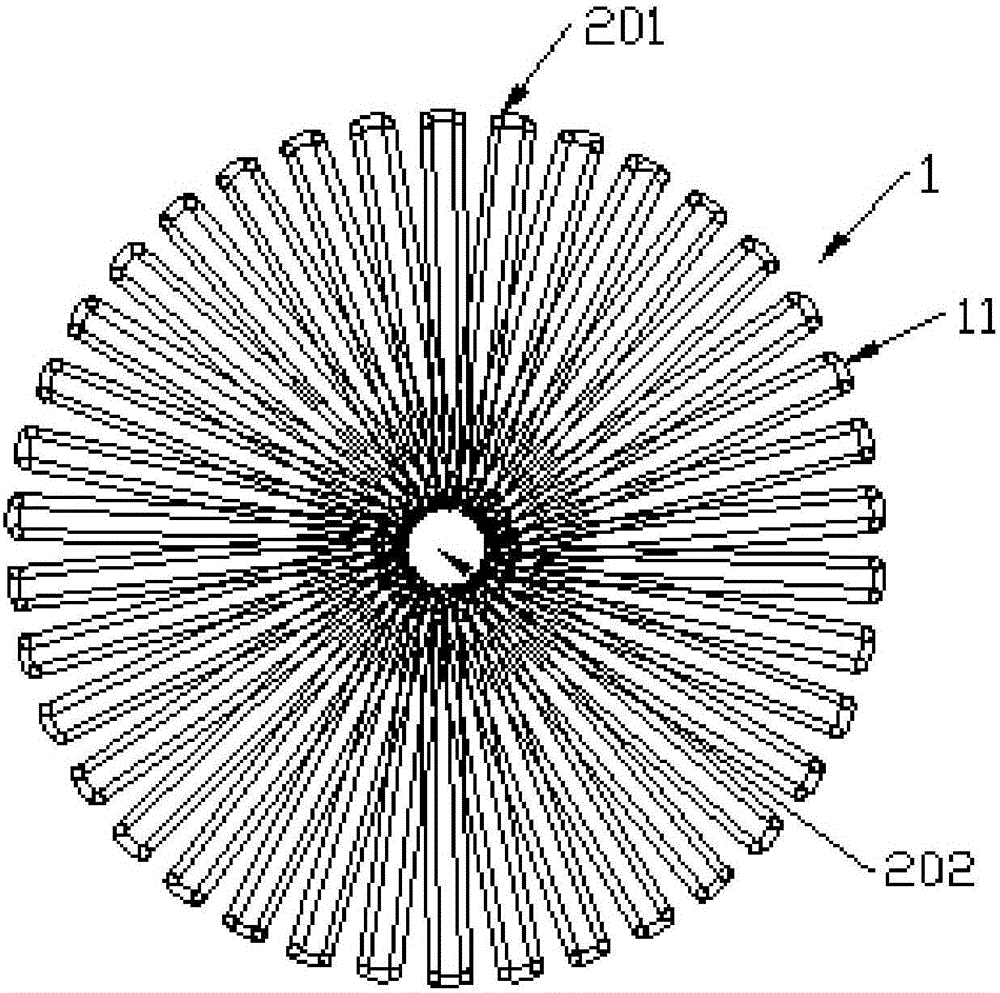

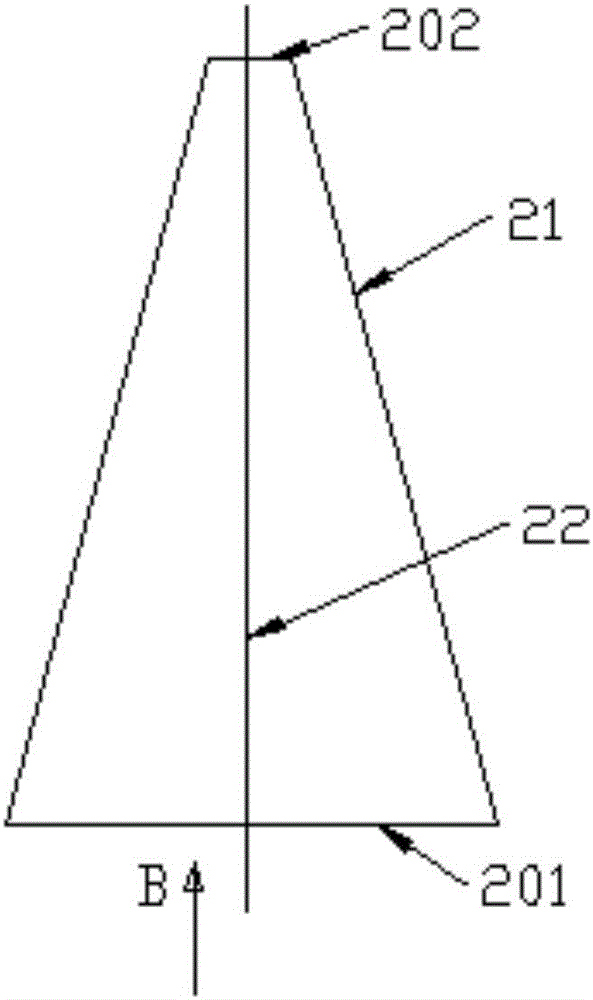

[0043] figure 1 The heat exchanger 1 in this embodiment includes the heat exchange tube 11 in the flow channel of the heat exchange gas, and the heat exchange tube 11 is arranged on a surface formed by rotating the busbar 21360 degrees around the vertical axis 22, Such as figure 2As shown, the gas flow channel has an incoming flow direction B, the incoming flow is the inflow of heat exchange gas, and flows out from the air outlet channel, that is, the heat exchanger 1 described in this embodiment can perform heat exchange at 360 degrees, making full use of At the same time, due to the fact that heat exchange can be performed at 360 degrees, the air outlet of the centrifugal fan 7 has a large contact area with the heat exchange tube 11 at the same time, so the heat exchange effect and heat exchange speed are greatly improved. In the heat exchanger 1 described in this embodiment, the formed surface is a tapered surface 20; the gap between adjacent heat exchange tubes 11 is a h...

Embodiment 2

[0047] The heat exchanger 1 in this embodiment includes heat exchange tubes 11 in the flow channel of the heat exchange gas, and the heat exchange tubes 11 are arranged on a surface formed by rotating the bus bar 21 around the vertical axis 22 by 360 degrees. , that is, the heat exchanger 1 described in this embodiment can exchange heat at 360 degrees, making full use of the space, and also because it can exchange heat at 360 degrees, the air from the centrifugal fan 7 contacts the heat exchange tube 11 at the same time The area is also large, so the heat transfer effect and heat transfer speed are greatly improved. In the heat exchanger 1 described in this embodiment, the formed surface is a cylindrical surface; the gap between adjacent heat exchange tubes 11 is a heat exchange gas channel. In the heat exchanger 1 of this embodiment, the axis 22 extends vertically, and the heat exchange tubes 11 go up and down along the generatrix 21 of the tapered surface 20, the structure i...

Embodiment 3

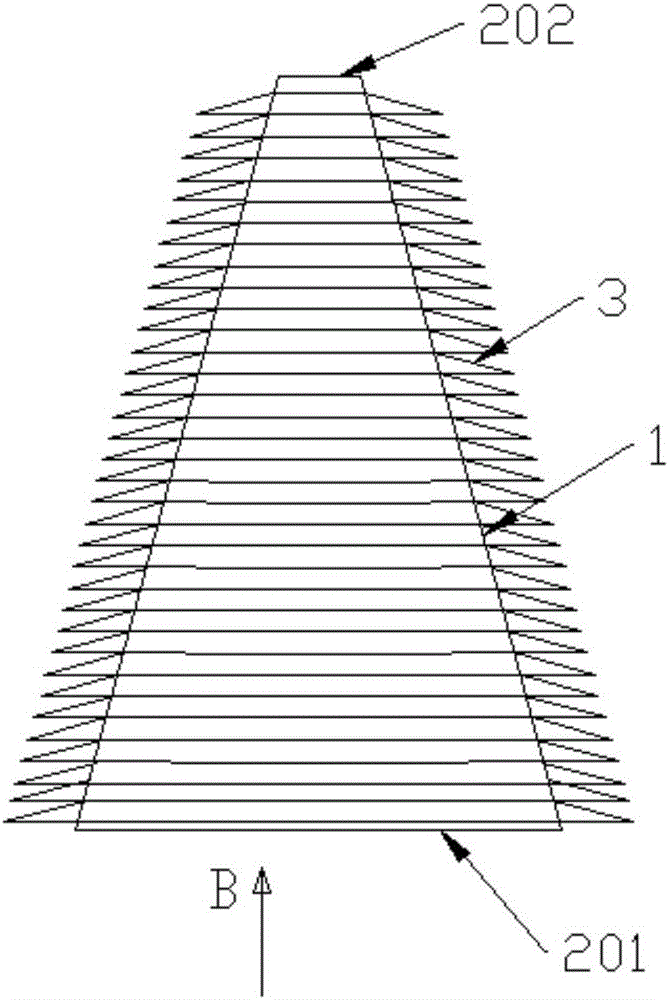

[0050] In this embodiment, on the basis of embodiment 1 or embodiment 2, the heat exchange tube 11 is also provided with multi-layer fins 3, such as Figure 3-6 shown, where Figure 4 To show more clearly, Figure 4 Only the top view of the heat exchanger in which the fin at the small end and the fin at the large end cooperate with the heat exchange tube is shown, and the other fins are omitted. Therefore, the contact area between the fins 3 and the heat exchange gas is further increased, thereby further improving the heat exchange effect.

[0051] Further, on the basis of the above-mentioned embodiments in this embodiment, the fins 3 are trumpet-shaped rings and the large mouth end 31 faces the incoming flow direction B. Therefore, the airflow of the wind flows between the adjacent two layers of fins 3 The heat exchange is carried out between them, and the heat exchange effect is further enhanced. In this embodiment, the angle A between the side wall of the fin 3 and the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com