Oil paint spraying system

A paint and spray booth technology, applied in coating, spray booth, spray device, etc., can solve the problems of difficult to control product quality, large difference in film thickness, unstable product quality, etc., to reduce the possibility and save paint. , the effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

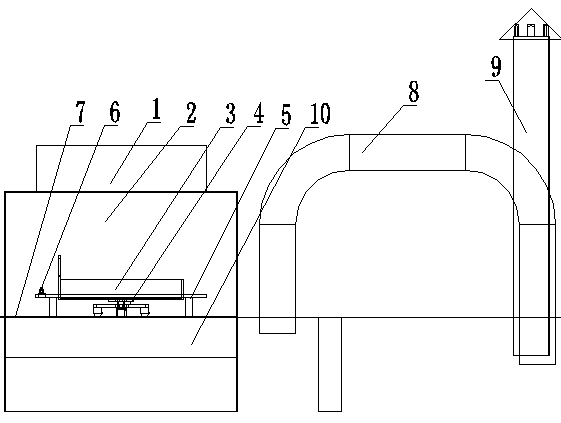

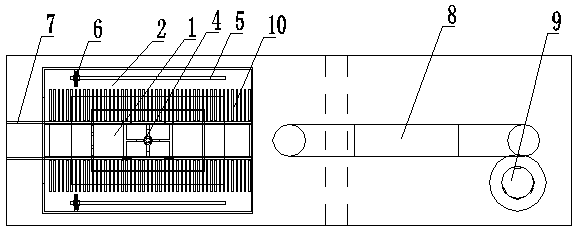

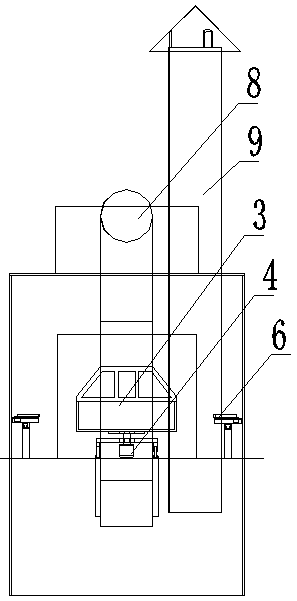

[0023] Such as Figure 1 to Figure 3 The paint spraying system shown includes the spray booth 2, the exhaust duct 10 is located below the ground level of the spray booth 2 and communicates with the spray booth 2 through a fence hole, the entrance of the exhaust duct is provided with paint absorbent cotton, and the exhaust pipe 8 is connected to the spray booth 2. The exhaust channel 10 is connected, the dust-removing water curtain 9 is connected with the exhaust pipe 8, and a purification pool and a circulating water pump are arranged under the dust-reducing water curtain 9, between the purifying water pool and the circulating water pump, and between the circulating water pump and the dust-reducing water curtain (9) Connected with the pipeline, the circulating water pump pumps the liquid in the purified pool to the dust-reducing water curtain 9, and the exhaust pipe behind the dust-reducing water curtain 9 is communicated with the induced draft fan. The top of the spray booth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com