Belt fall point dust removal system

A drop and belt technology, applied in the field of belt drop point dust removal systems, can solve the problems of uneven wind speed at the mouth of the vacuum hood, unsatisfactory cleaning effect, and improper matching of the size of the mouth of the hood, so as to achieve ideal dust removal effect and reduce The effect of inducing air volume and smooth movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

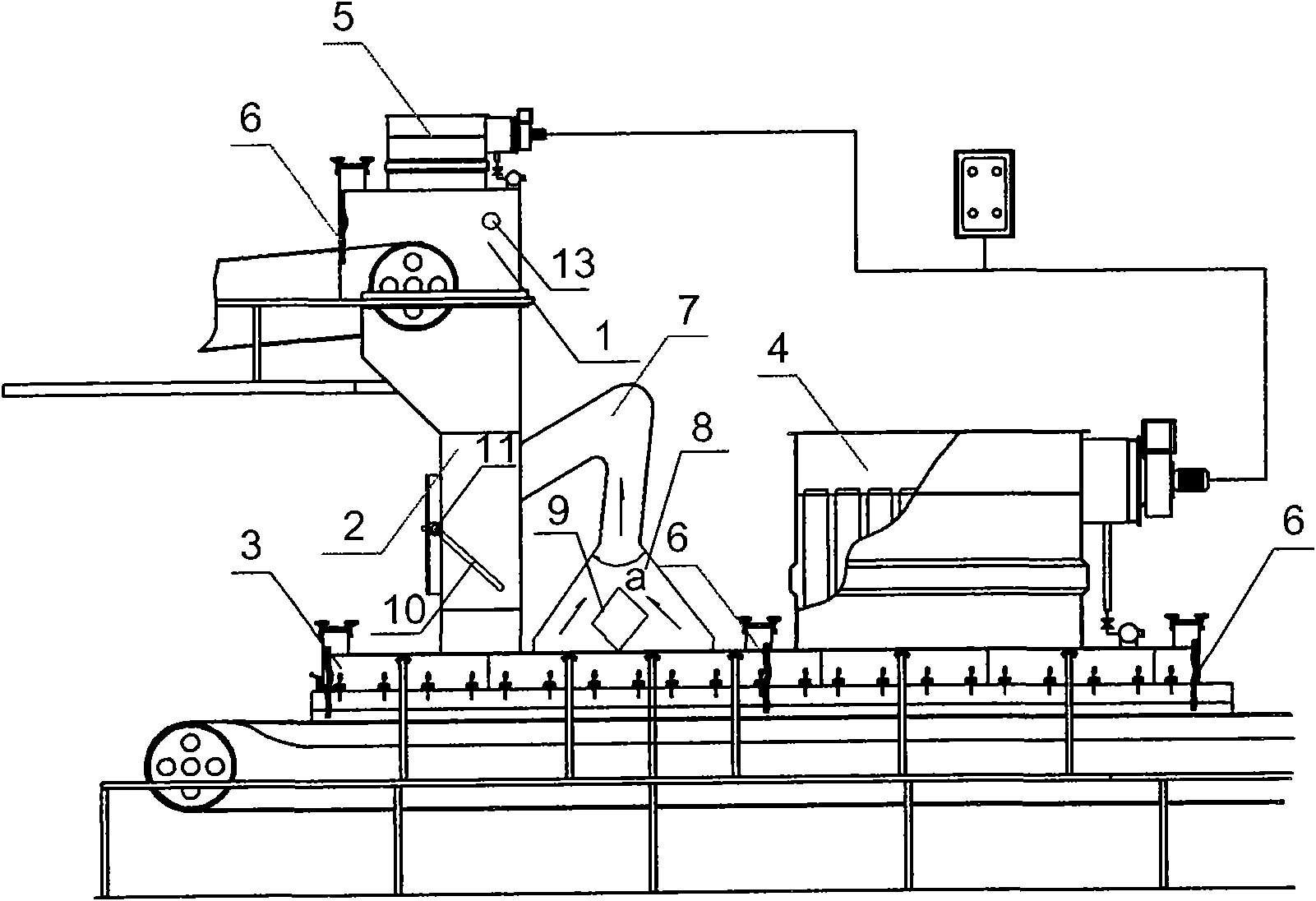

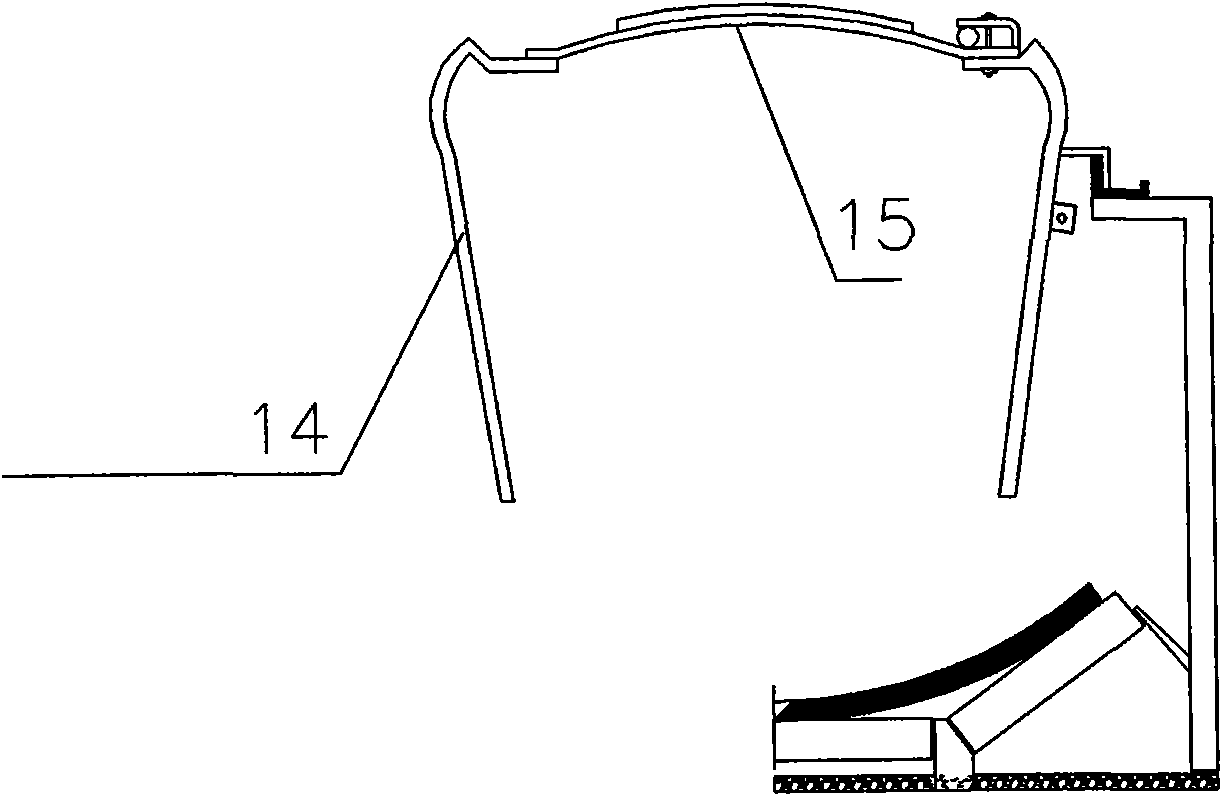

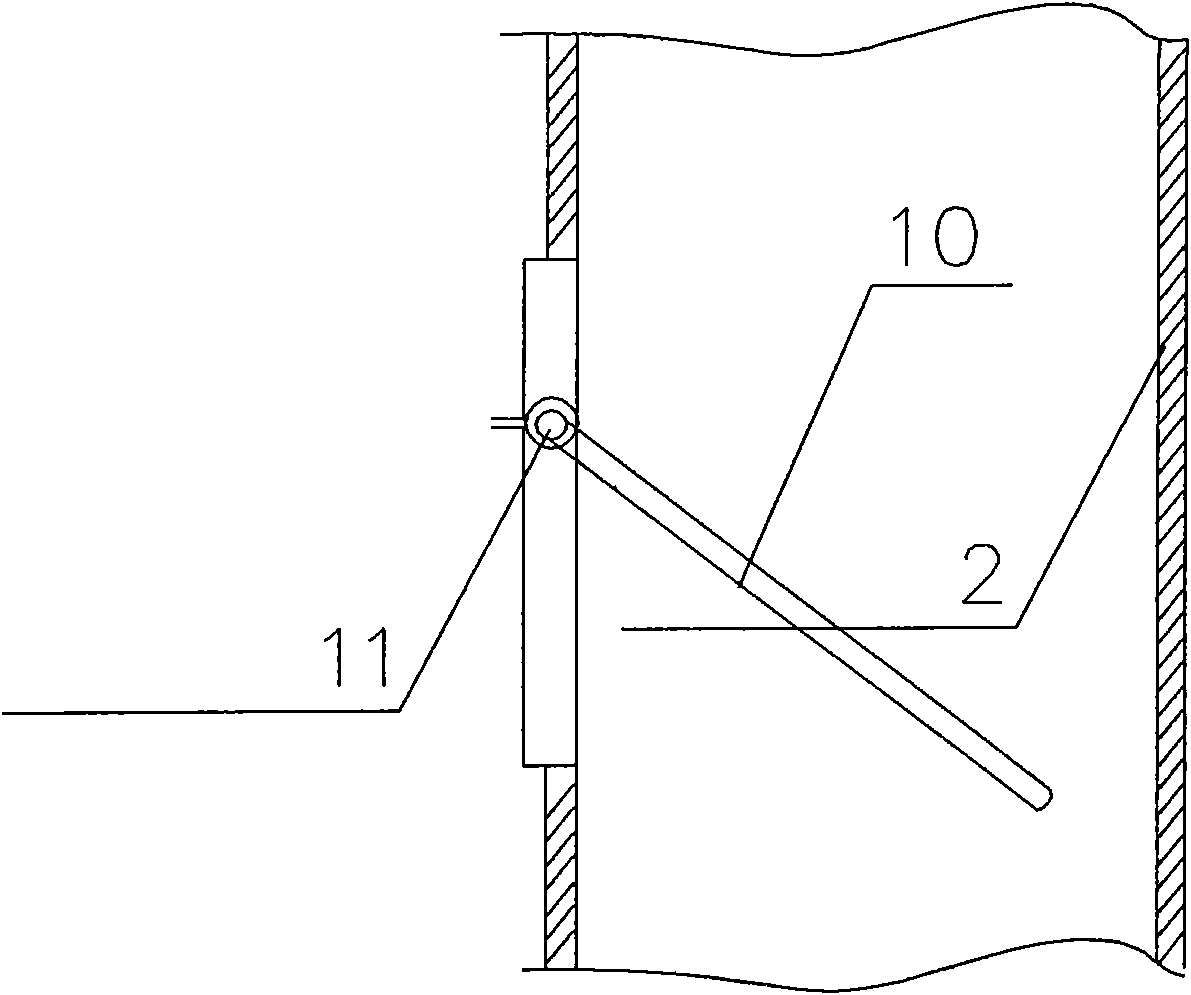

[0020] Such as figure 1 As shown, a belt drop point dust elimination system includes: head closure cover 1, material chute 2 and body lower sealing cover 3; The discharge port of the material flow tank 2 is connected with the feed port of the lower sealing cover 3 of the body; the first dust collector 4 is arranged on the top of the lower sealing cover 3 of the body; the first dust removal The air inlet of device 4 communicates with the air outlet of body lower sealing cover 3; The top of described machine head sealing cover 1 is provided with second dust remover 5; The cavities communicate with each other; the airtight cover 3 at the lower part of the machine body and the airtight cover 1 of the machine head are fixedly equipped with a soft dust-absorbing curtain 6; when the material falls from a high place through the material chute 2, a large amount of air is induced. In order to eliminate the positive pressure and increase the buffering effect, the present invention is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com