Method and apparatus for measuring gas transmission rates of deformable or brittle materials

a technology of brittle materials and gas transmission rates, which is applied in the field of apparatus and methods for measuring the transmission rate and nano leakage of gas, and can solve problems such as false positives, failure of mass spectrometers to operate in high-vacuum systems, and failure to detect false positives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

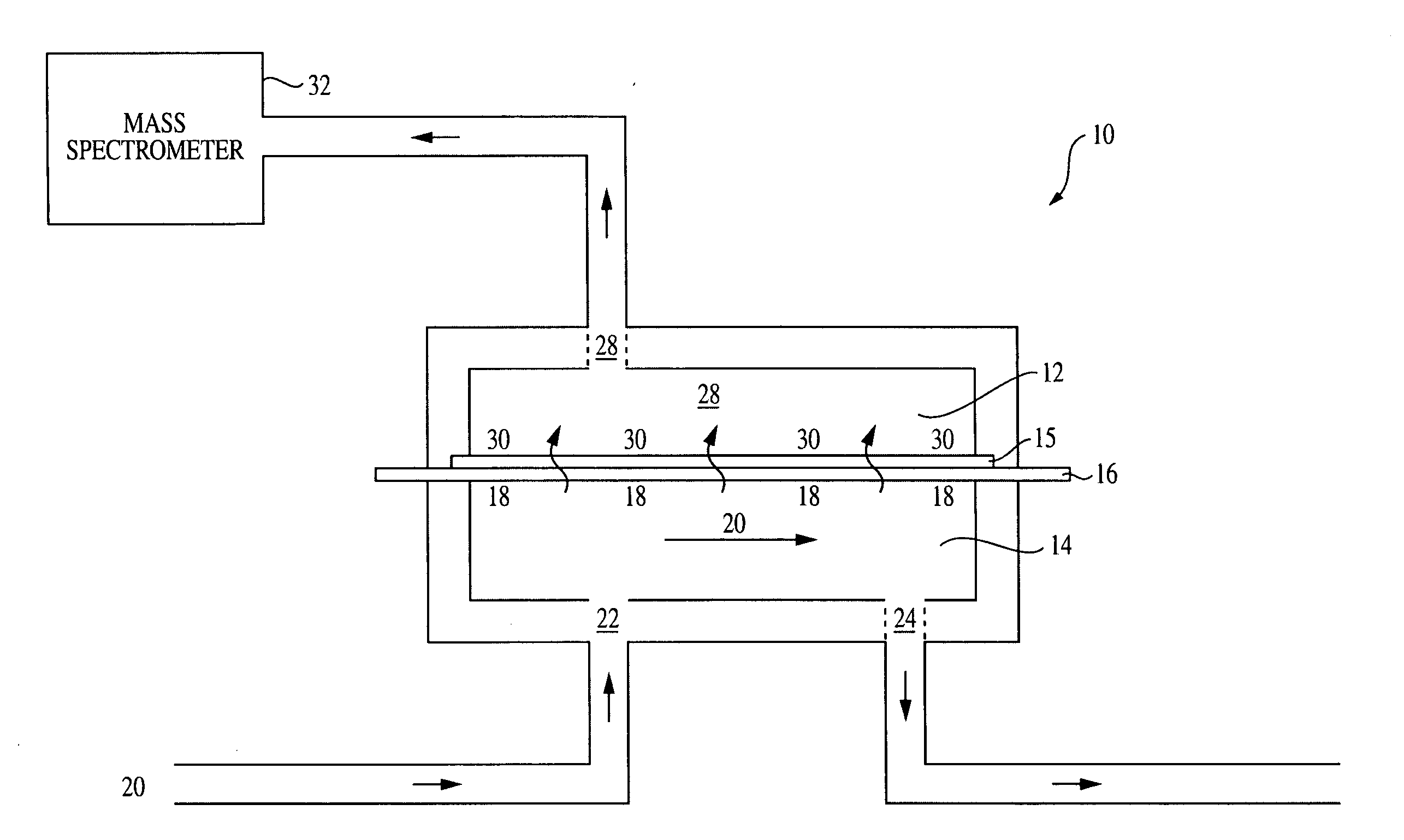

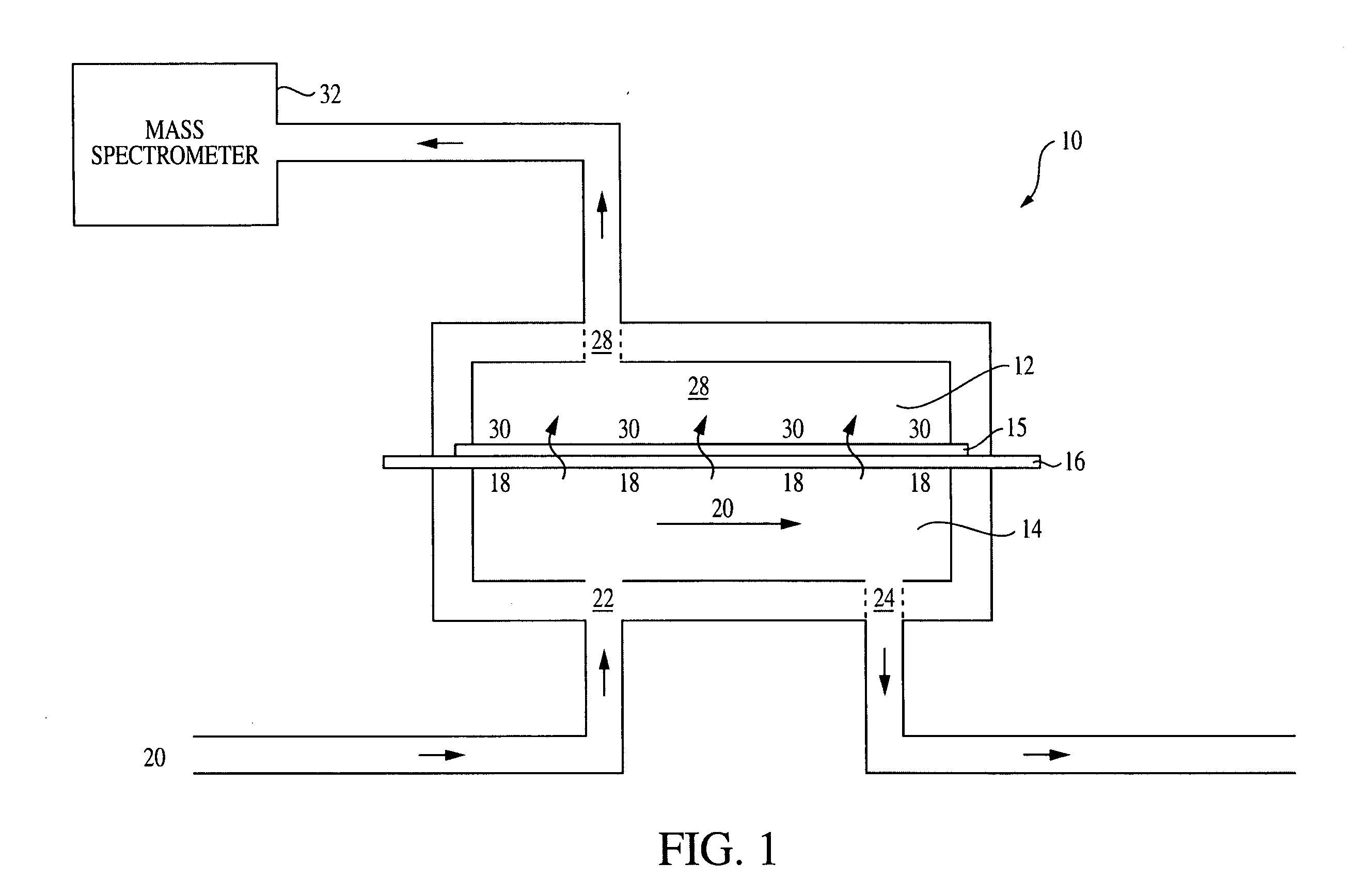

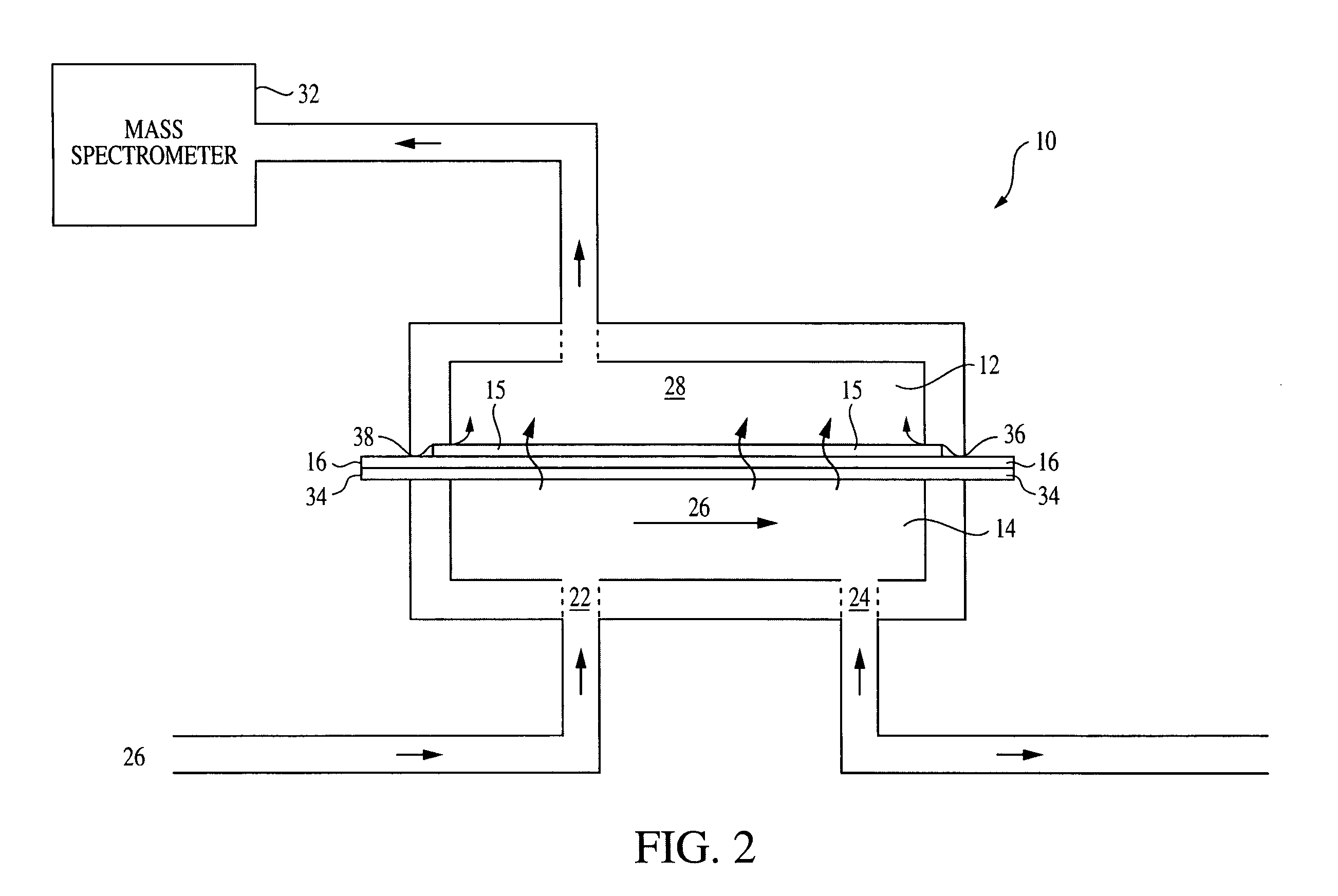

[0021]FIG. 1 illustrates the test setup for conducting the first step of the method in accordance with the present invention. A test chamber 10 includes an upper diffusion cell 12 and a lower diffusion cell 14. A guard material 16 is positioned on top of the lower diffusion cell 14 and a support grid 15 is positioned on top of the guard material. The upper and lower diffusion cells 12 and 14 are then clamped together with support grid 15 and guard material 16 therebetween. It is desirable, but not essential, for the guard material 16 to have a certain rigidity so that it does not deform under the high-vacuum system of the mass spectrometer but the guard material should not be so rigid or brittle that it fractures. Polyester materials such as polyethylene terephthalate (e.g. Mylar® available from Dupont, Wilmington, Del.); polystyrenes such as acrylonitrile butadiene styrene; and polycarbonate materials such as GE Plastics™ and Lexan® may be used. In the alternative, it is not essent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| gas transmission rate | aaaaa | aaaaa |

| mass spectrometer | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com