Ejector with spray nozzle position adjustable and device

A technology of injectors and nozzles, applied in the direction of injection devices, liquid injection devices, etc., can solve problems such as the decline in the efficiency of injectors, and achieve the effect of improving performance and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

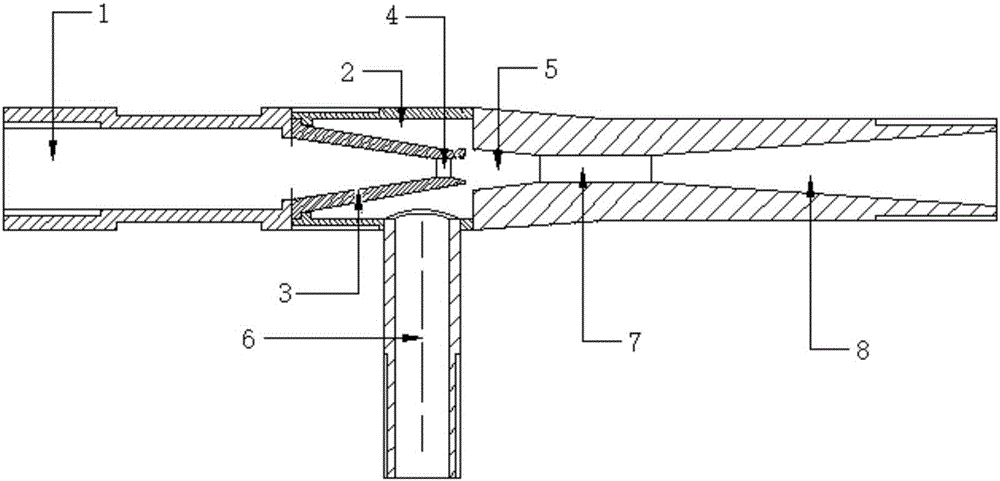

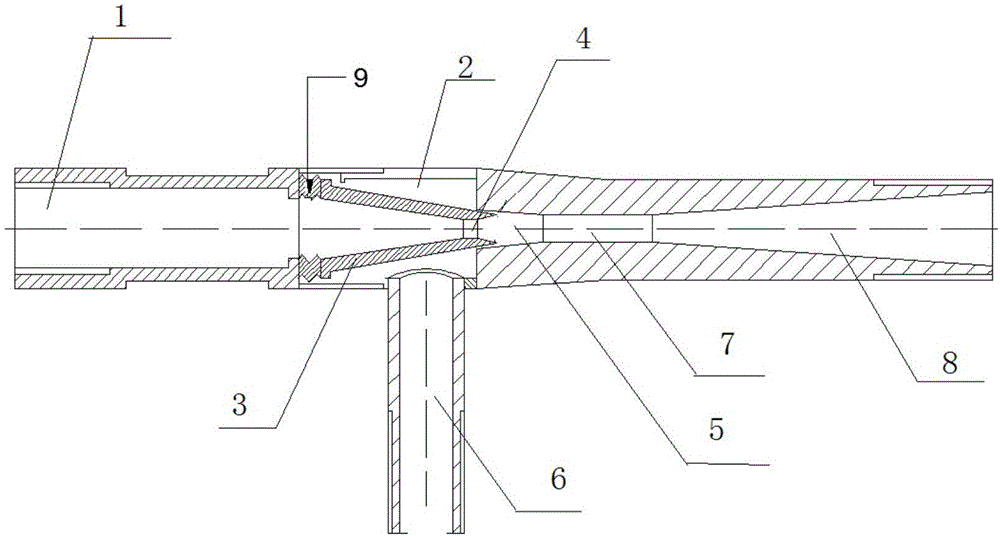

[0030] figure 1 Structural diagram of a traditional injector. Such as figure 1 The structure of the conventional injector shown is:

[0031] The injector includes a primary flow pipe 1, a nozzle 3, a receiving chamber 2, a secondary flow pipe 6, a mixing chamber and a diffusion chamber 8; wherein, the mixing chamber includes two mixing sections, namely an equal pressure mixing section 5 and an equal area mixing section 7.

[0032] The nozzle 3 is connected to the outlet of the primary flow pipe 1, and the nozzle 3 crosses the receiving chamber 2 and enters the mixing chamber; the diffusion chamber 8 is connected to the outlet of the mixing chamber; the secondary flow pipe 6 is placed in the mixing chamber Below, into the mixing chamber.

[0033] How the injector works:

[0034] The primary stream steam (that is, power steam) enters the nozzle 3 for adia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com