A needle control device capable of adjusting the nozzle area of the injector and the injector

A nozzle area, control device technology, applied in the direction of spraying device, spraying device, etc., can solve the problems of poor environmental adaptability, complex control system, bulky stepping motor, etc., and achieve the effect of improving performance and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

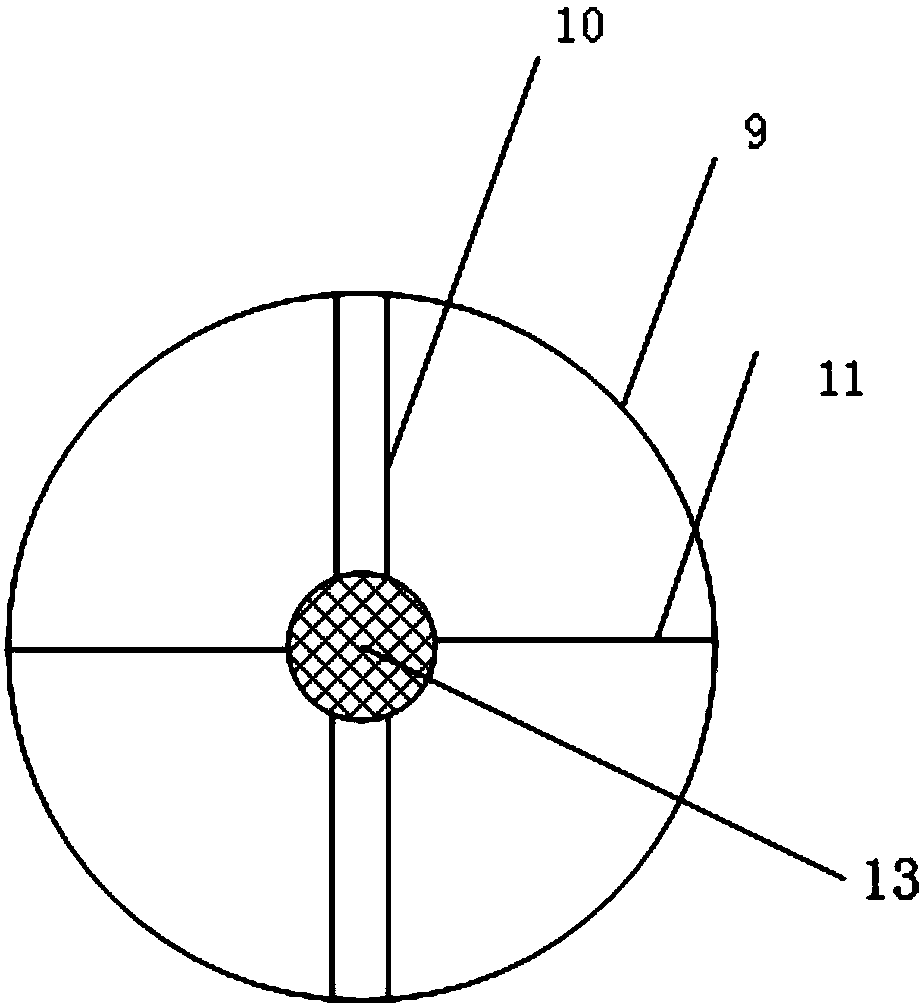

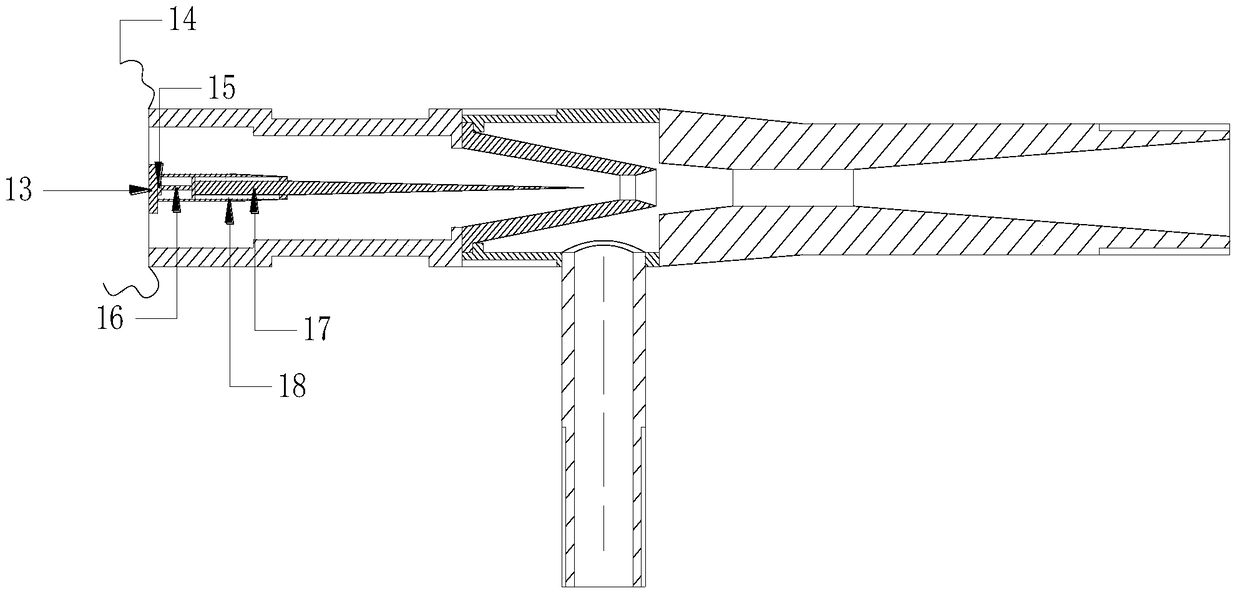

[0052] Such as image 3 and Figure 7 As shown, the needle motion control device includes: a heating resistor 15 arranged inside the needle support tube 18 and connected to a fixed bracket, the heating resistor 15 is connected to the injection needle 17 through a material 16 that expands with heat and contracts with cold; the heating wire of the heating resistor 15 14 is drawn out through the hollow beam 10 of the fixed support;

[0053] Power is supplied to the heating resistor 15 through wires, and the temperature of the resistor is changed by changing the power supply current or voltage. The thermal expansion and contraction material 16 will be deformed due to the principle of thermal expansion and contraction, thereby driving the needle 17 to move.

[0054] The thermal expansion and contraction material 16 is heated by the heating resistor 15, so that the thermal expansion and contraction material 16 is deformed to control the movement of the needle 17 to a position close...

Embodiment 2

[0059] Such as Figure 4 and Figure 8 As shown, the needle motion control device includes: an electromagnet 19 arranged inside the needle support tube 18 and connected to the fixed bracket, a permanent magnet 22 is arranged at the end of the needle 17 near the end of the fixed bracket, and the electromagnet 19 passes through the spring 21 Connect with the permanent magnet 22; the energized wire 20 connected with the electromagnet 19 is drawn out through the hollow beam 10 of the fixed bracket; by changing the magnitude of the current of the electromagnet 19, the electromagnet 19 and the permanent magnet 22 act to control the movement of the spray needle 17; When the electromagnet 19 is not energized, that is, when the spring 21 is not deformed, the position of the spray needle 17 is the initial position. When passing a current to the electromagnet 19 to generate a repulsive force between it and the permanent magnet 22, control the needle 17 to move to the right to reach the ...

Embodiment 3

[0063] Such as Figure 5 and Figure 9 As shown, the needle motion control device includes: a sealing piston 24 is arranged inside the needle support tube 18, a cavity 30 is provided between the sealing piston 24 and the fixed bracket, and the sealing piston 24 is connected with the injection needle 17; The hollow beam 10 leads out the fluid introduction pipe 23, and the fluid introduction pipe 23 communicates with the cavity 30 through the fluid introduction port 25;

[0064] The fluid is introduced or extracted into the cavity 30 through the fluid introduction tube 23. According to the volume of the fluid introduced or extracted, when the fluid is extracted, the pressure in the cavity 30 decreases, the piston 24 drives the injection needle 17 to move to the left, and the piston 24 drives the injection needle. 17 moves to the left; when the fluid is injected, the pressure in the cavity 30 increases, pushing the piston 24 to move to the right, and the piston 24 drives the spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com