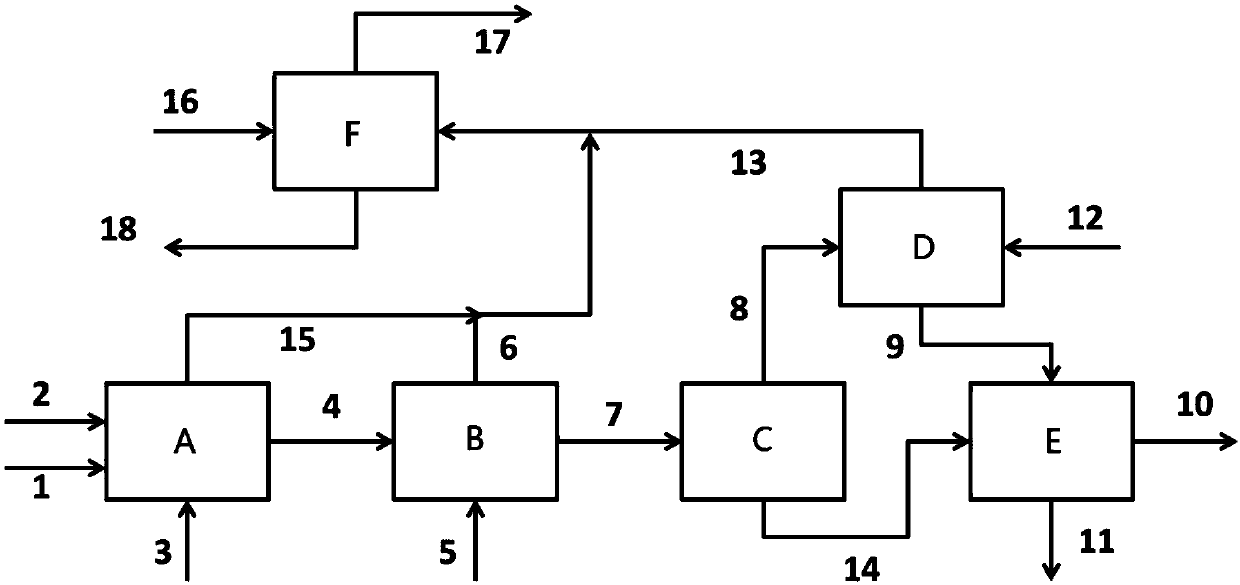

Preparation method and system of mono-isocyanate

A monoisocyanate and isocyanate technology, applied in the field of monoisocyanate preparation, can solve the problems of increased total organic matter, urea or hydrochloride, poor economy, etc., and achieve the effect of low solid waste and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

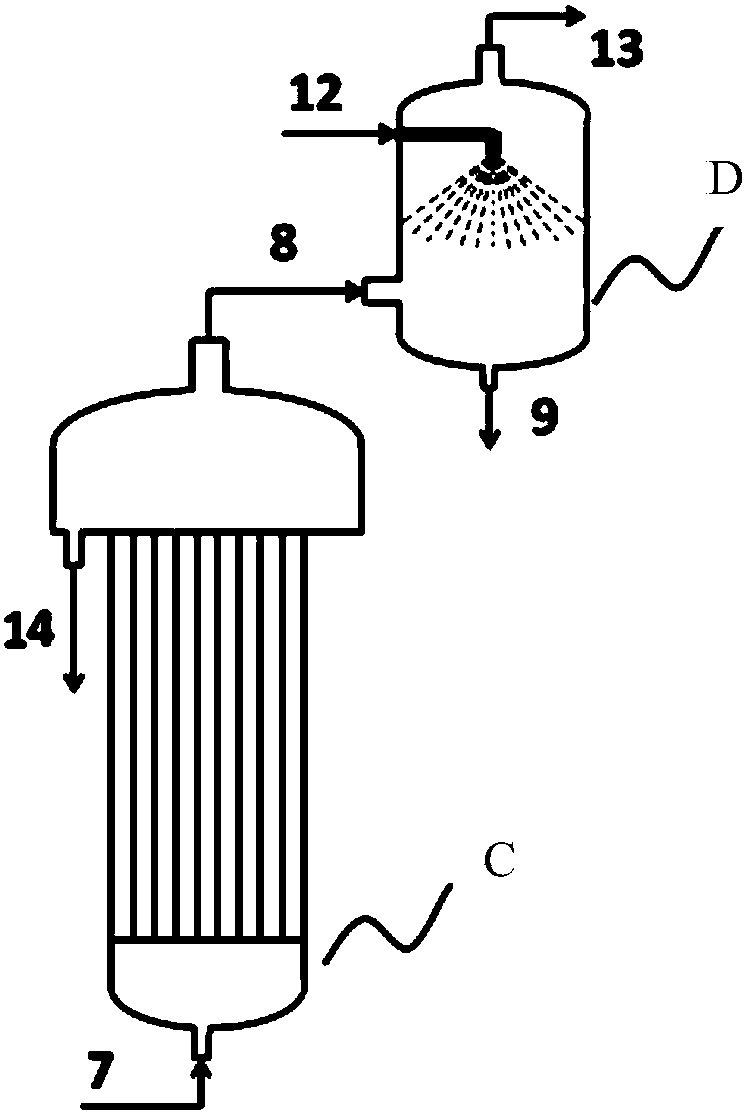

Method used

Image

Examples

Embodiment 1

[0069] Embodiment 1 methyl isocyanate

[0070]In this example, according to the process described above, methyl isocyanate is prepared by gas-phase phosgenation, and the phosgene gasified and heated to 350°C is heated to 350°C with a flow rate of 2000kg / h at a flow rate of 250kg / h. The methylamine gas is sent to the gas phase phosgenation reactor at the same time for phosgenation reaction, the reaction pressure is 10KPa (gauge pressure), the reaction temperature is 350°C, the mixed gas obtained from the gas phase phosgenation reaction is absorbed by the inert solvent chloroform After obtaining the phosgenation reaction solution and the gas phase phosgenation reaction tail gas with a concentration of 20%, the temperature of the reaction solution is controlled at 32°C; The phosgene is removed by gas stripping to obtain the reaction solution with phosgene removed and the tail gas stripped with hydrogen chloride; the reaction solution with phosgene removed is sent to a cracker for...

Embodiment 2

[0073] Embodiment 2 ethyl isocyanate

[0074] In this example, according to the process described in Example 1, ethyl isocyanate was prepared by gas-phase phosgenation, and the phosgene gasified and heated to 320 ° C was used at a flow rate of 900 kg / h, and the flow rate was 150 kg / h and heated to Ethylamine gas at 320°C is simultaneously fed into the gas phase phosgenation reactor for phosgenation reaction, the reaction pressure is 5KPa (gauge pressure), the reaction temperature is 340°C, the mixed gas obtained from the gas phase phosgenation reaction is absorbed by the inert solvent toluene After obtaining the phosgenation reaction liquid and the gas phase phosgenation tail gas with a concentration of 20%, the temperature of the reaction liquid is controlled at 50°C; The phosgene is removed by gas stripping to obtain the reaction liquid and hydrogen chloride stripping tail gas; the reaction liquid is sent to the cracker for cracking, the cracking temperature is 135 ° C, and ...

Embodiment 3

[0077] Embodiment 3 isopropyl isocyanate

[0078] In this example, according to the process described in Example 1, isopropyl isocyanate is prepared by gas phase phosgenation, and the phosgene gasified and heated to 330 ° C is heated at a flow rate of 900 kg / h and a flow rate of 200 kg / h The isopropylamine gas up to 330°C is simultaneously sent into the gas phase phosgenation reactor for phosgenation reaction, the reaction pressure is 0KPa (gauge pressure), the reaction temperature is 350°C, the mixed gas obtained from the gas phase phosgenation reaction is inert solvent chlorine Obtain concentration after benzene absorption and be 20% phosgenation reaction liquid and gas phase phosgenation reaction tail gas, during reaction liquid temperature control at 60 ℃; ) to carry out air stripping to catch phosgene, and obtain the reaction liquid and the hydrogen chloride stripping tail gas that have completely removed phosgene; send the reaction liquid that has completely removed phos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com