Sodium chloride ammonium chloride separated crystallization process and device

An ammonium chloride and sodium chloride technology, which is applied in the field of sodium chloride ammonium chloride salt separation crystallization process and devices, can solve the problems of affecting the process of enterprise projects, incomplete treatment of waste liquid, and high energy consumption in the treatment process, and achieves functional efficiency. The effect of low consumption, reduced dependence on boiler installations, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

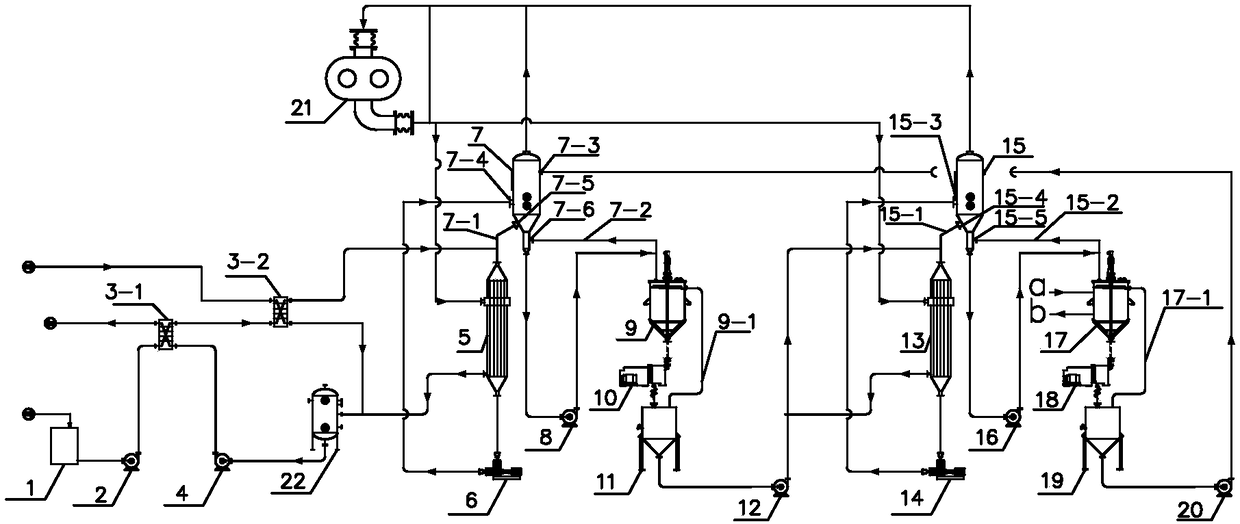

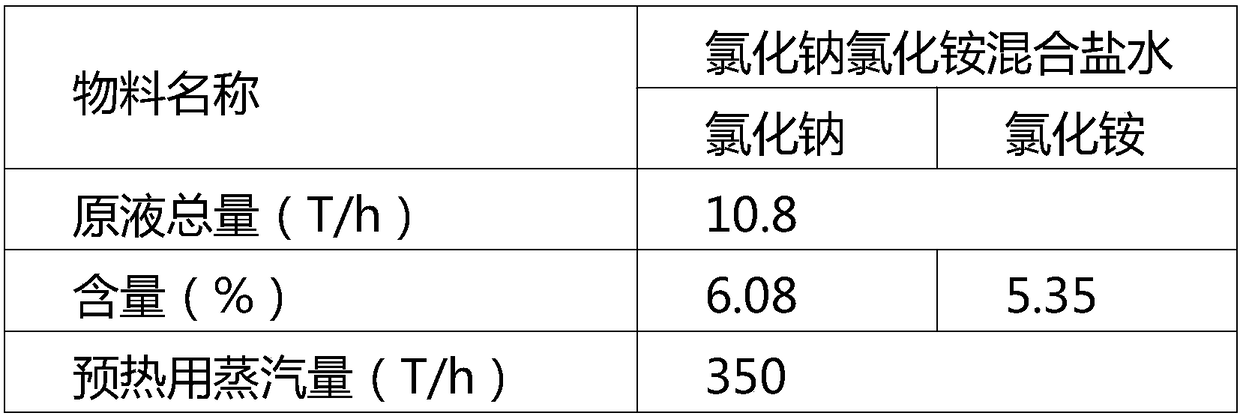

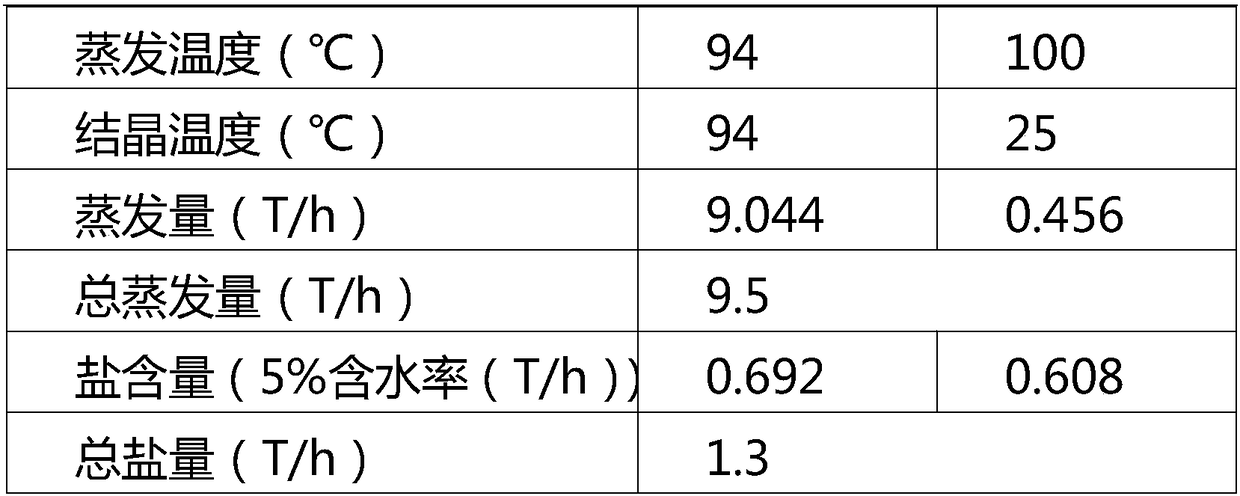

[0039] Such as figure 1 As shown, a sodium chloride ammonium chloride salt separation crystallization process, the mass fraction of sodium chloride in the waste water is 6.08%, the mass fraction of ammonium chloride is 5.35%, and the total flow of waste water is 10.8t / h, including the following steps:

[0040]S1. Preheating, waste water is pumped into the preheater from the raw material buffer tank 1 through the feed pump 2 for preliminary temperature rise, and the temperature rise is divided into two steps: the waste water first passes through the hot water preheater (ie, hot water plate preheater) 3- 1 Heating, the heat source is high-temperature condensed water at 105°C, and the waste liquid can be heated to 82°C; and then heated by a steam preheater (steam plate preheater) 3-2, the heat source is steam at 110°C, and the waste water can be heated to 93-95°C;

[0041] S2. evaporation and concentration to obtain supersaturated sodium chloride waste water, the waste water aft...

Embodiment 2

[0065] Such as figure 1 As shown, the structure of the device in this example is the same as that in Embodiment 1, and will not be repeated here.

[0066] A sodium chloride and ammonium chloride salt separation crystallization process, the mass fraction of sodium chloride in wastewater is 5.53%, the mass fraction of ammonium chloride is 7.02%, and the total flow of wastewater is 24.78t / h, comprising the following steps:

[0067] S1. Preheating, waste water is pumped into the preheater from the raw material buffer tank 1 through the feed pump 2 for preliminary temperature rise, and the temperature rise is divided into two steps: the waste water first passes through the hot water preheater (ie, hot water plate preheater) 3- 1 Heating, the heat source is high-temperature condensed water at 105°C, and the waste liquid can be heated to 81°C; and then heated by a steam preheater (steam plate preheater) 3-2, the heat source is steam at 110°C, and the waste water can be heated to 95°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com