Thermally stable cocurrent gasification system and associated methods

a gasification system and cocurrent technology, applied in the field of gasification apparatus, can solve the problems of increasing the downtime and operating cost of the gasifier, the oxidation and cracking of the pyrolysis gas, and the low gas residence time within the bed and the capital cost of the system, so as to reduce the amount of solid waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

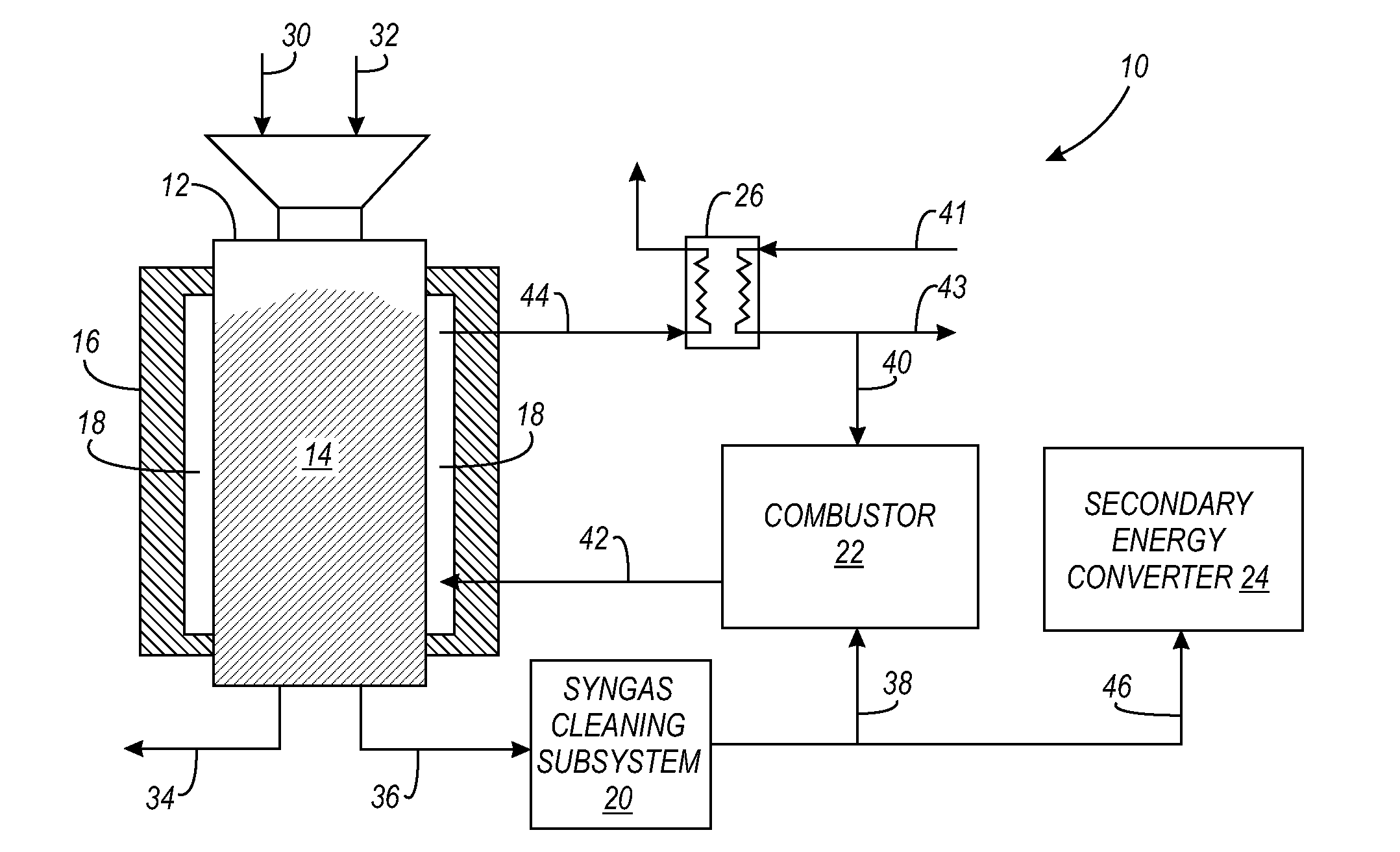

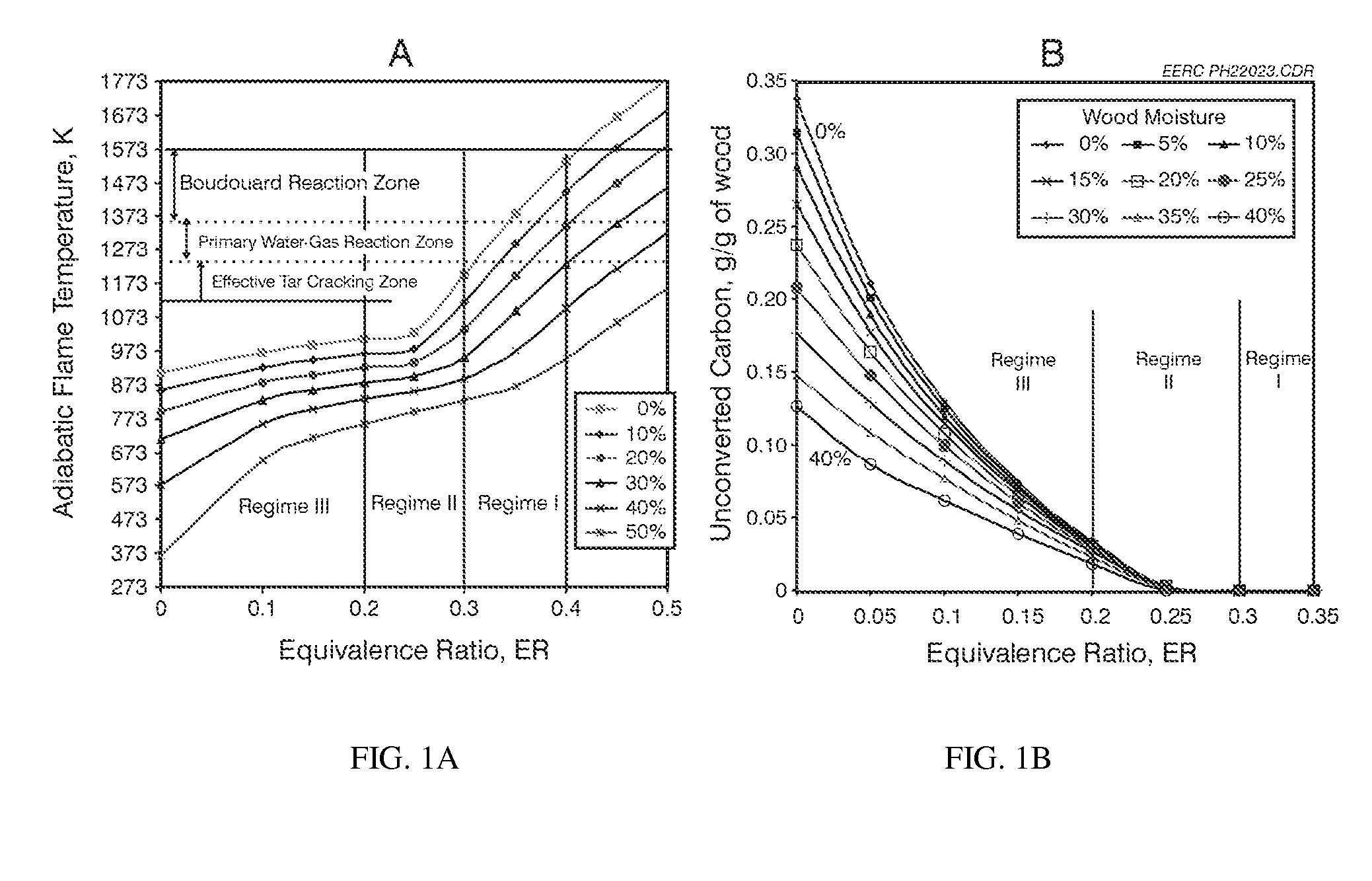

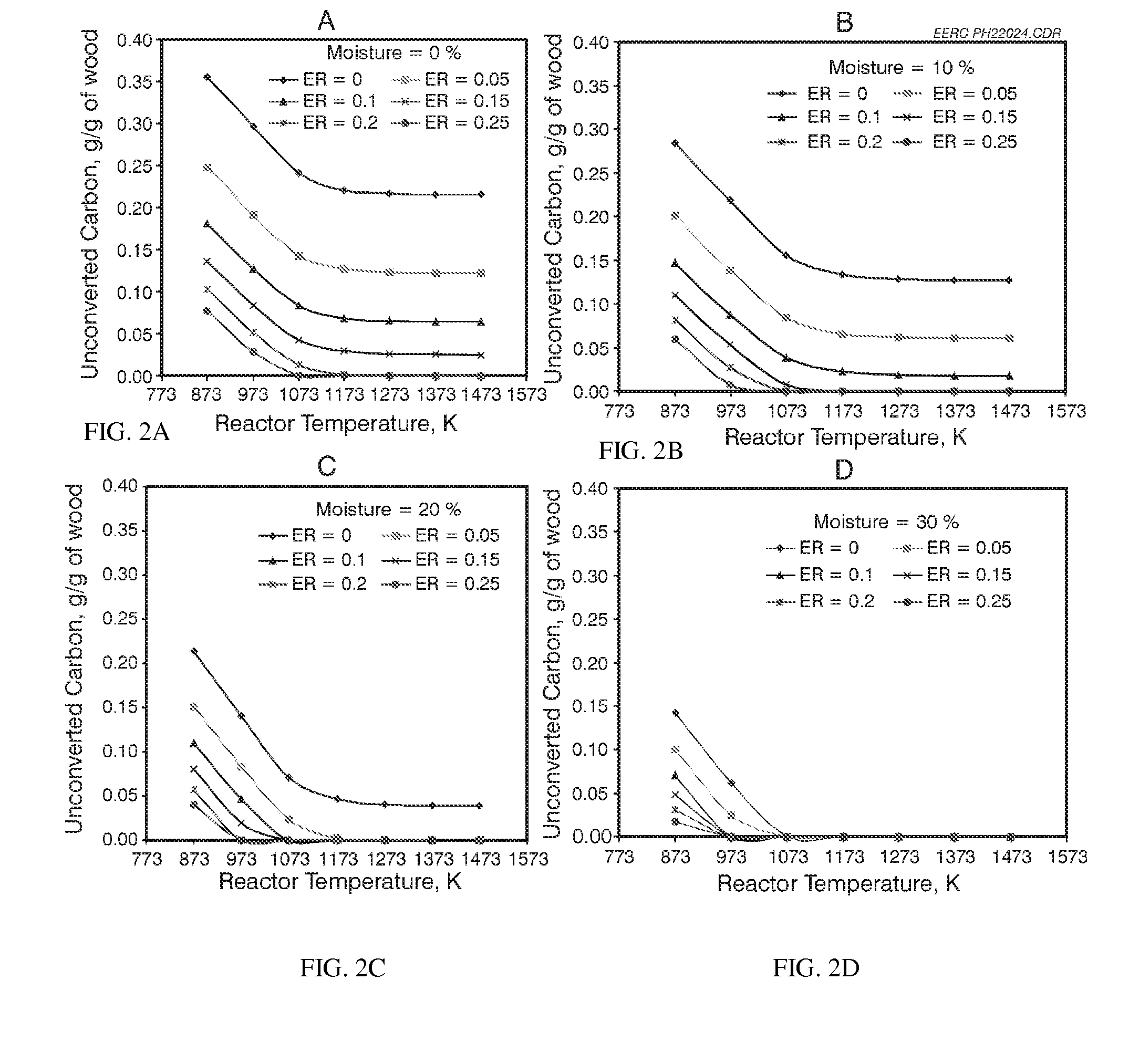

[0024]The present invention overcomes the disadvantages in the prior art described above by maintaining a wide high-temperature heating zone along the length of a gasifier (described in detail below). The wide high-temperature heating zone is maintained by circulating or flowing hot combustible gases through an annular space around the hot zone of the reactor. This creates a quasi-isothermal temperature zone large enough to ensure much longer residence times of gases in the reaction zone of the reactor, particularly reduction zone. In one example, the minimum temperature is 800° C., but preferably greater than 900° C. The minimum residence time is dictated by the feed, temperature, and moisture conditions within the gasifier and is essentially the residence time necessary to achieve near-total destruction of tars and conversion of char. The long temperature zone prevents channeling of pyrolysis gases and eliminates cold spots below 800° C. The hot space around the reactor minimizes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| isothermal temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com