Device and method for electrochemically preparing high-purity battery-grade lithium hydroxide

A lithium hydroxide, electrochemical technology, applied in the field of electrochemistry, can solve problems such as environmental pollution and reduction of anodic oxidation reaction potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

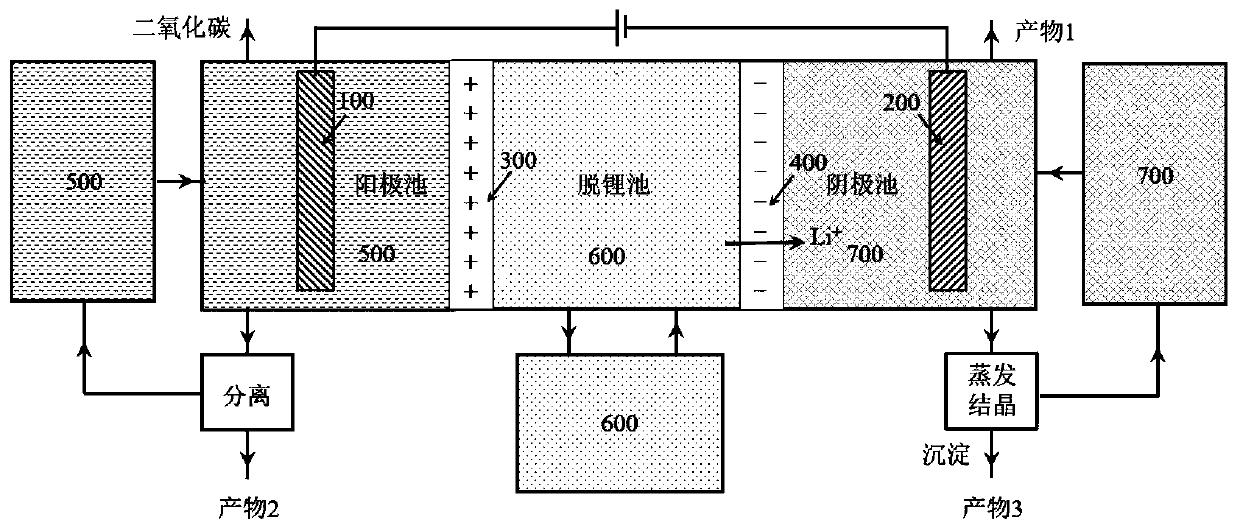

[0080] Such as figure 1 As shown, the device for electrochemically preparing high-purity battery-grade lithium hydroxide of the present invention includes two electrocatalytic electrodes and two diaphragms: an oxidation electrode (100), a hydrogen production electrode (200), an anion exchange membrane (300) and a cation exchange membrane (400);

[0081] The oxidation electrode (100) and the anion exchange membrane (300) form an anode cell;

[0082] The hydrogen production electrode (200) and the cation exchange membrane (400) form a cathode cell;

[0083] It also includes a delithiation pool, the delithiation pool is connected to the anode pool through the anion exchange membrane (300); the delithiation pool is connected to the cathode pool through the cation exchange membrane (400);

[0084] The electrolyte solution in the anode pool is an aqueous solution of organic matter (500), and the aqueous solution of organic matter (500) is used as a sacrificial agent to control the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com