Method for synthesizing 2-nitro-3-methylbenzoic acid

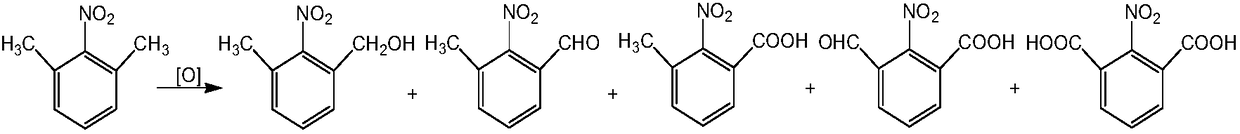

A technology of toluic acid and m-toluic acid is applied in the preparation of nitro compounds, organic chemistry, etc., and can solve the problem of low yield of 2-nitro-3-methylbenzoic acid, many nitration by-products, and product problems such as low selectivity, to achieve the effect of optimizing process parameters, simple process and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Put 500 g of concentrated nitric acid with a mass fraction of 92% into a four-necked glass bottle with a volume of 1000 mL, start mechanical stirring, and cool down to -15°C. Add 50g of toluic acid powder with an average particle size of 180 microns into a glass bottle for reaction, keep stirring during the reaction and control the reaction temperature at -15°C, and stop the reaction after 10 minutes of reaction to obtain the main product 2-nitro- The nitration reaction liquid of 3-methylbenzoic acid, through HPLC analysis, the conversion ratio of raw material m-toluic acid is 99.1%, the selectivity of target product 2-nitro-3-methylbenzoic acid is 75.2%, to the obtained nitration Water was added to the reaction liquid, and filtered to obtain 2-nitro-3-methylbenzoic acid product with a purity of 99.2%.

Embodiment 2

[0045] Put 500 g of concentrated nitric acid with a mass fraction of 94% into a four-neck glass bottle with a volume of 1000 mL, turn on mechanical stirring, and cool down to -17°C. Add 66.6g of toluic acid powder with an average particle size of 160 microns into a glass bottle for reaction. During the reaction, keep stirring and control the reaction temperature -17°C. After 120 minutes of reaction, the reaction is terminated, and the main product is 2-nitro The nitration reaction solution of -3-methylbenzoic acid was analyzed by HPLC, the conversion rate of raw material m-methylbenzoic acid was 99.3%, and the selectivity of target product 2-nitro-3-methylbenzoic acid was 78.4%. Add water to the obtained nitration reaction solution, and filter to obtain 2-nitro-3-methylbenzoic acid product with a purity of 99.4%.

Embodiment 3

[0047] Put 500 g of concentrated nitric acid with a mass fraction of 96% into a four-neck glass bottle with a volume of 1000 mL, turn on mechanical stirring, and cool down to -17.8°C. Add 74.7g of toluic acid powder with an average particle size of 150 microns into a glass bottle for reaction. During the reaction, keep stirring and control the reaction temperature -17.8°C. After 35 minutes, the reaction is terminated, and the main product is 2-nitro -The nitration reaction liquid of 3-methylbenzoic acid, analyzed by HPLC, the conversion rate of raw material m-toluic acid is 99.4%, the selectivity of target product 2-nitro-3-methylbenzoic acid is 79.8%. Add water to the obtained nitration reaction solution, and filter to obtain 2-nitro-3-methylbenzoic acid product with a purity of 99.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com